Aerosol aspirator

An aspirator and aerosol technology, applied in the field of aerosol aspirators, can solve problems such as the inability to maintain the quality of the solution, that is, aerosol, and thermal deterioration, and achieve the effect of ensuring quantitativeness and quality, and preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

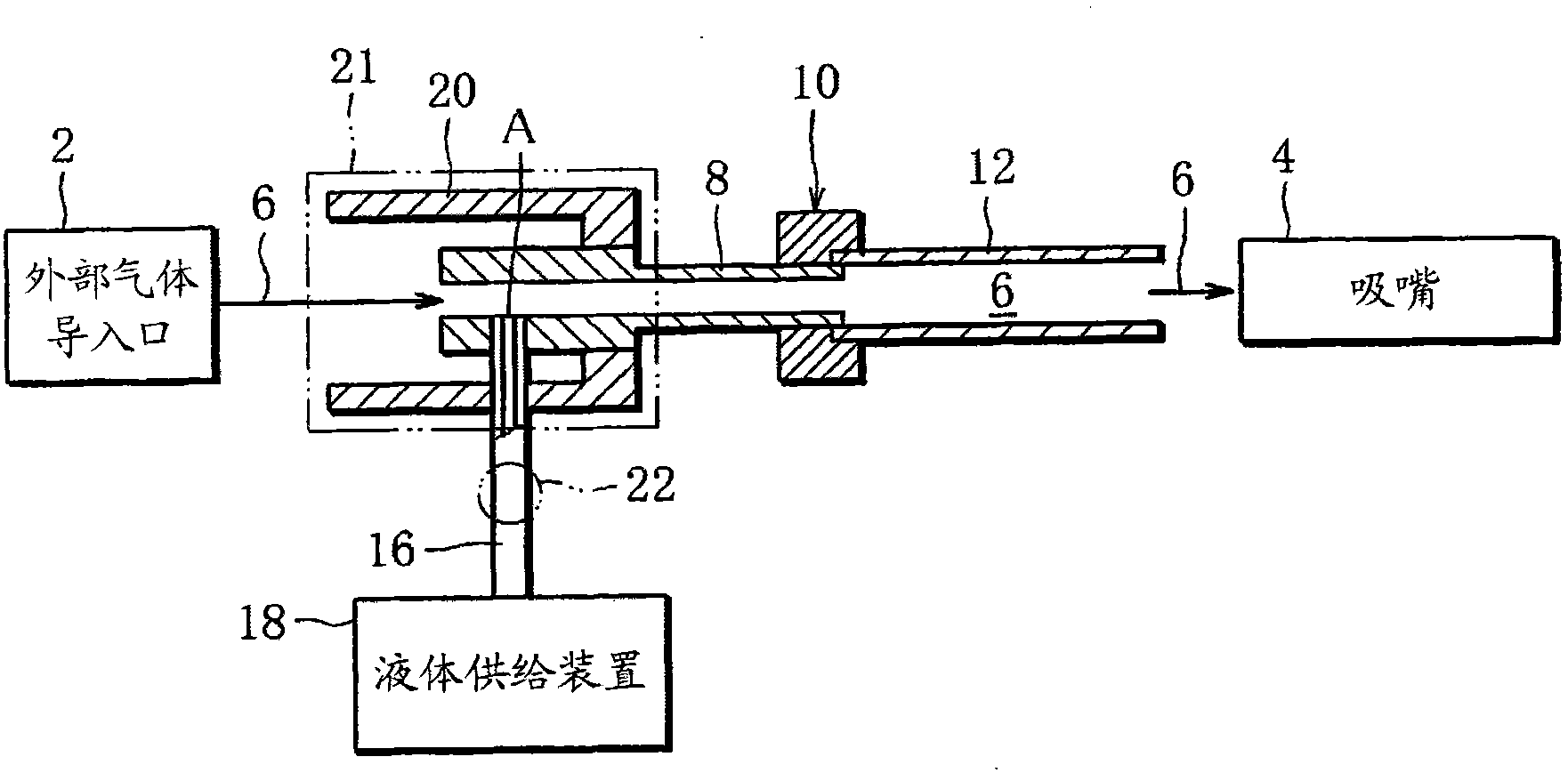

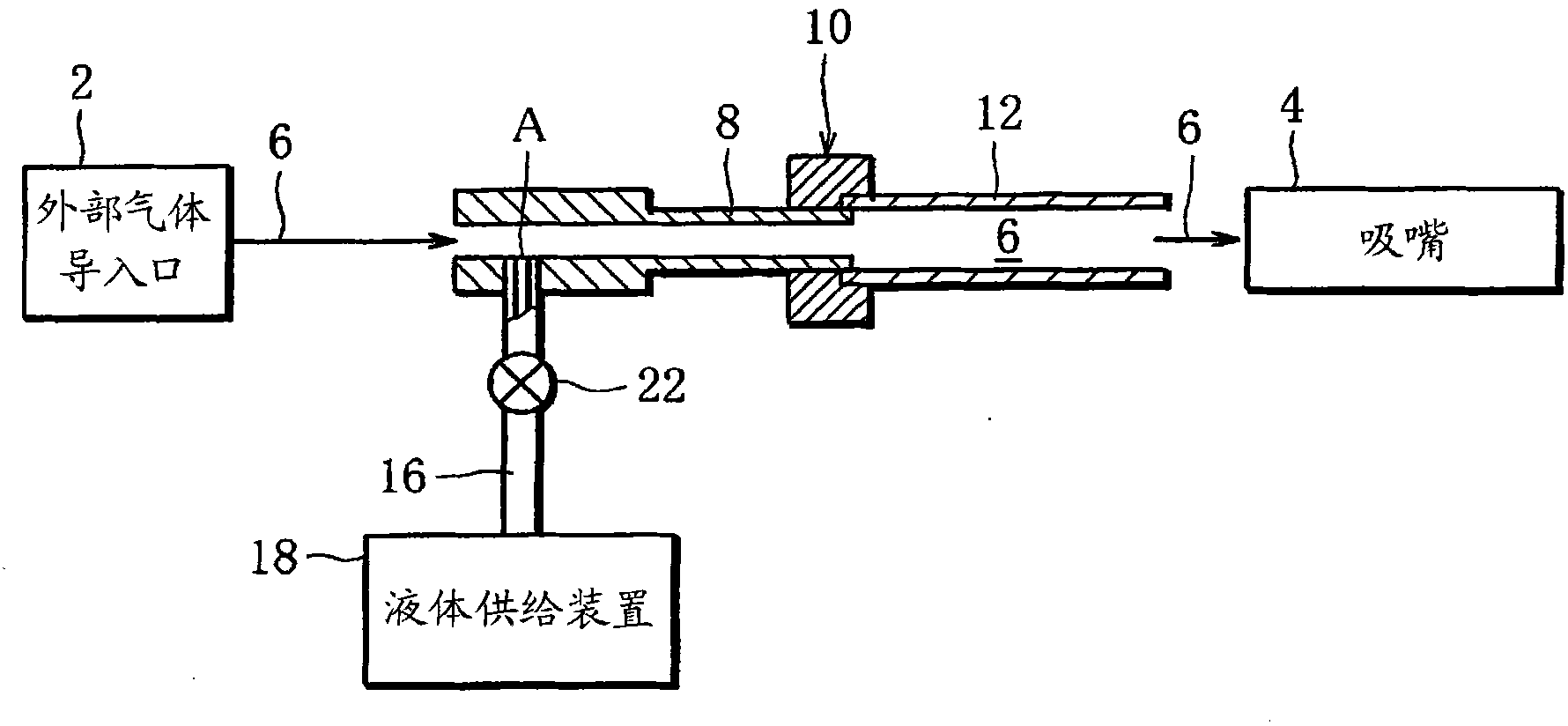

[0022] refer to figure 1 , the aerosol inhaler of the first embodiment has a housing (not shown). The housing has an external air introduction port 2 at its front end, and a suction nozzle 4 protruding from the housing at its rear end. In addition, the casing defines a gas mist generating flow path 6 inside thereof, and the gas mist generating flow path 6 extends from the external air inlet 2 to the suction nozzle 4 . Specifically, in the case of this embodiment, a part of the gas mist generation flow path 6 is formed by the air introduction tube 8 and the tubular ceramic heater 12 .

[0023] The air introduction pipe 8 is formed of stainless steel and has a stepped shape. That is, the air introduction pipe 8 has a large-diameter portion located on the outside-air introduction port 2 side and a small-diameter portion located on the suction nozzle 4 side. The small-diameter end, that is, the downstream end of the air introduction pipe 8 is connected to a ceramic heater 12 vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com