Anode active material and secondary lithium battery

A technology for positive active materials and lithium secondary batteries, applied in secondary batteries, active material electrodes, battery electrodes, etc., can solve problems such as difficulty in inhibiting the reaction between positive active materials and electrolytes, poor cycle characteristics, and thermal stability problems , to achieve the effect of improving high temperature storage characteristics, preventing dissolution, and increasing discharge potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

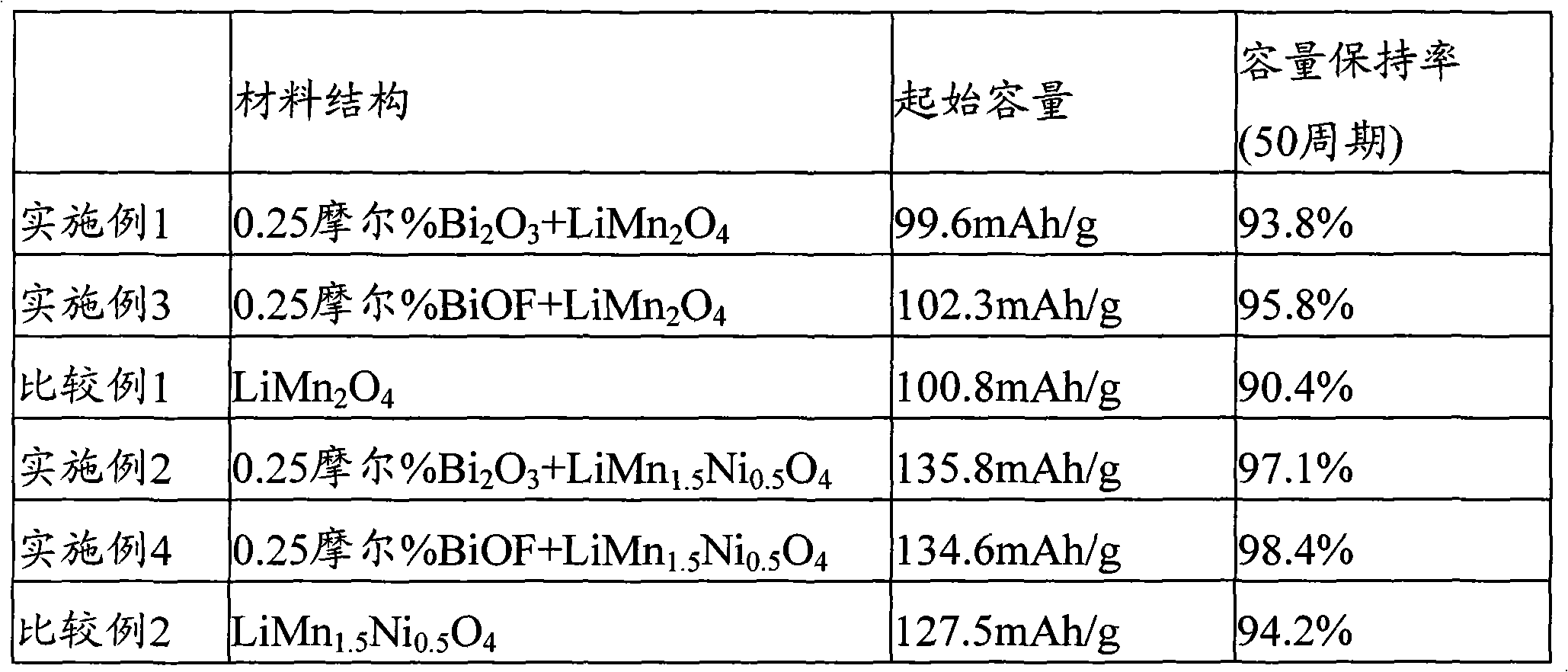

Embodiment 1

[0096] (Example 1) preparation has Bi-containing 2 o 3 Positive electrode active material for surface modification layer

[0097] Put 50g of LiMn in the stirred reactor that 600ml distilled water is housed 2 o 4 , followed by NH 4 OH to adjust the pH to 10. Prepare Bi(NO 3 ) 3 ·5H 2 O solution, at this time, relative to 100 mol% LiMn 2 o 4 , using 0.25 mol% Bi(NO 3 ) 3 ·5H 2 O.

[0098] Under the condition of keeping the temperature at 30°C, to the stirring LiMn 2 o 4 Bi(NO 3 ) 3 ·5H 2 O solution. After stirring the resulting mixture for 6 hours, it was filtered to prepare the surface with Bi(OH) 3 LiMn 2 o 4 .

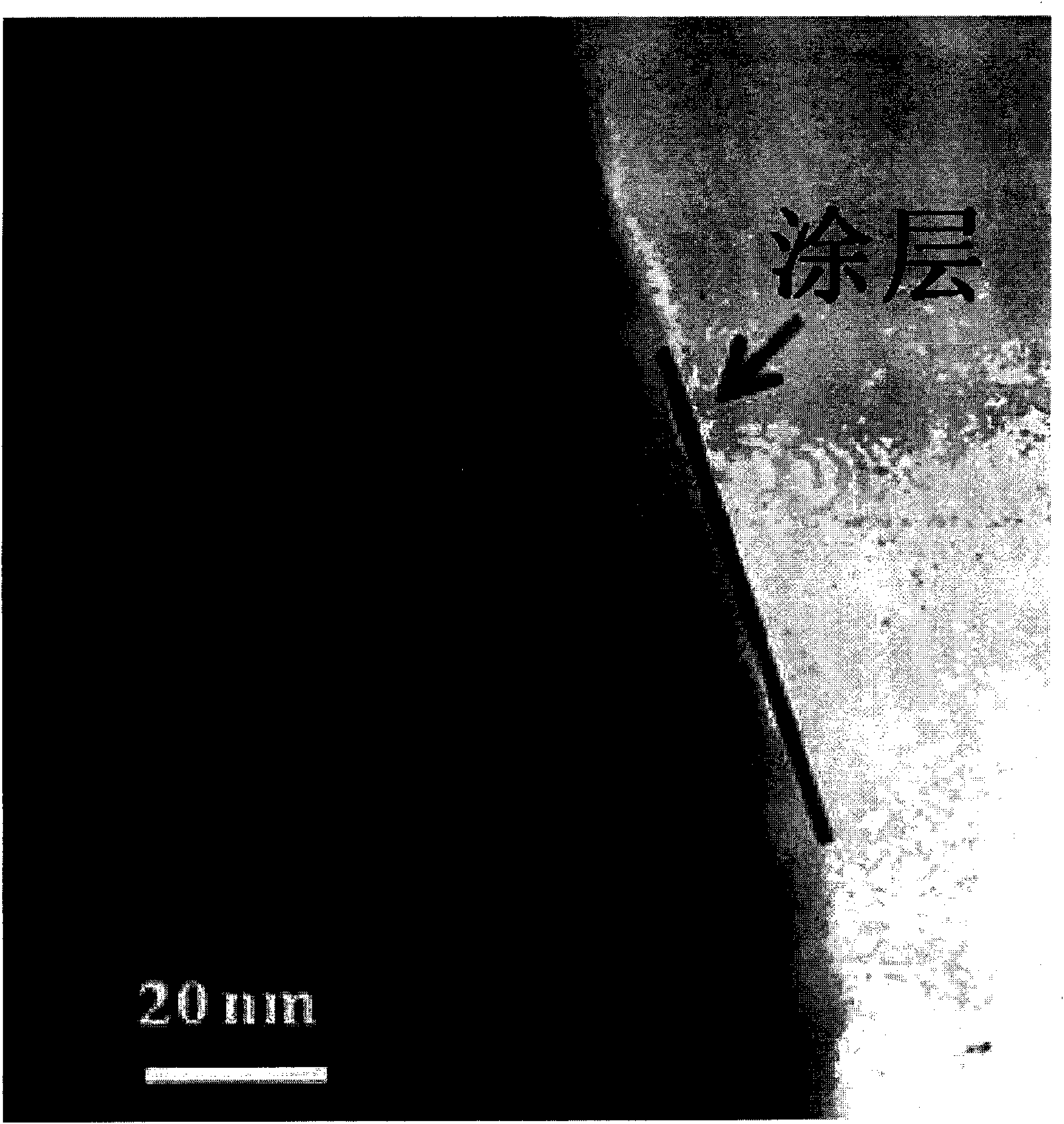

[0099] After drying the obtained compound in a constant temperature bath at 110°C for 12 hours, heat treatment was carried out at 400°C for 5 hours to prepare LiMn 2 o 4 Bi on the surface 2 o 3 surface-modified cathode active materials. In the prepared cathode active material, compared to LiMn 2 o 4 , the Bi 2 o 3 The coating amount is 0...

Embodiment 2

[0101] In addition to changing the active compound to LiMn 1.5 Ni 0.5 o 4 In addition, the same method as in Example 1 was used for surface modification.

Embodiment 3

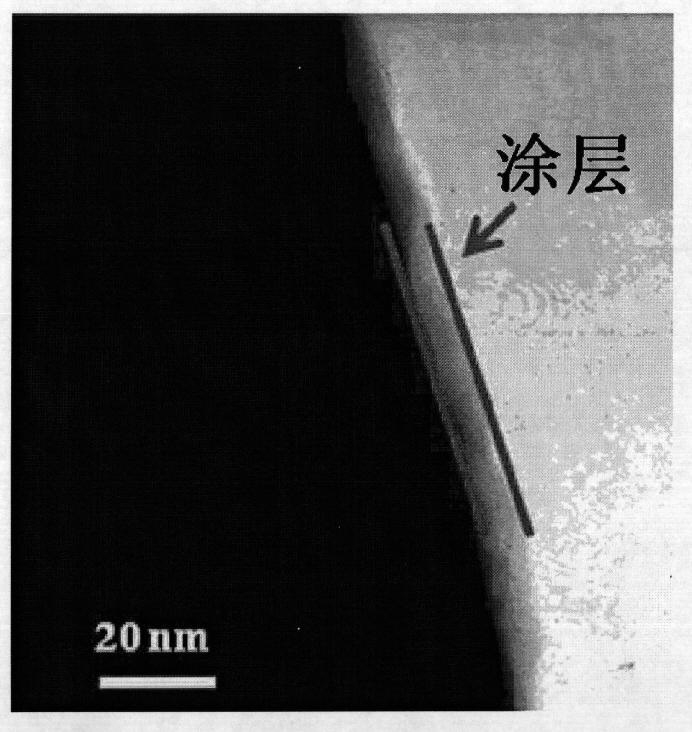

[0102] (Example 3) Preparation of positive electrode active material with BiOF-containing surface modification layer

[0103] Put NH in a stirred reactor with 600ml of distilled water 4 F and make it dissolve, at this time relative to 100 mol% LiMn 2 o 4 , the NH 4 The dosage of F was 0.75 mol%. Add the LiMn of 50g to the resulting solution afterwards 2 o 4 After using NH 4 OH to adjust the pH to 7.

[0104] Dissolve Bi(NO) in 400ml distilled water 3 ) 3 ·5H 2 O to prepare bismuth compound precursors. At this time, relative to 100 mol% LiMn 2 o 4 , the Bi(NO 3 ) 3 ·5H 2 The amount of O used is 0.25 mol%.

[0105] Under the condition of keeping the temperature at 30° C., the bismuth compound precursor solution was slowly put into the stirred reactor. After stirring the resulting mixture for 6 hours, it was filtered to prepare 4 Bi 3 f 10 LiMn 2 o 4 .

[0106] The resulting product was dried in a constant temperature bath at 110°C for 12 hours, and then he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com