Blanking and drawing composite die for aluminium shell of capacitor

A capacitor and composite mold technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems affecting product quality and production efficiency, difficult to reduce production costs, waste and defective products, etc. The effect of cracking and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

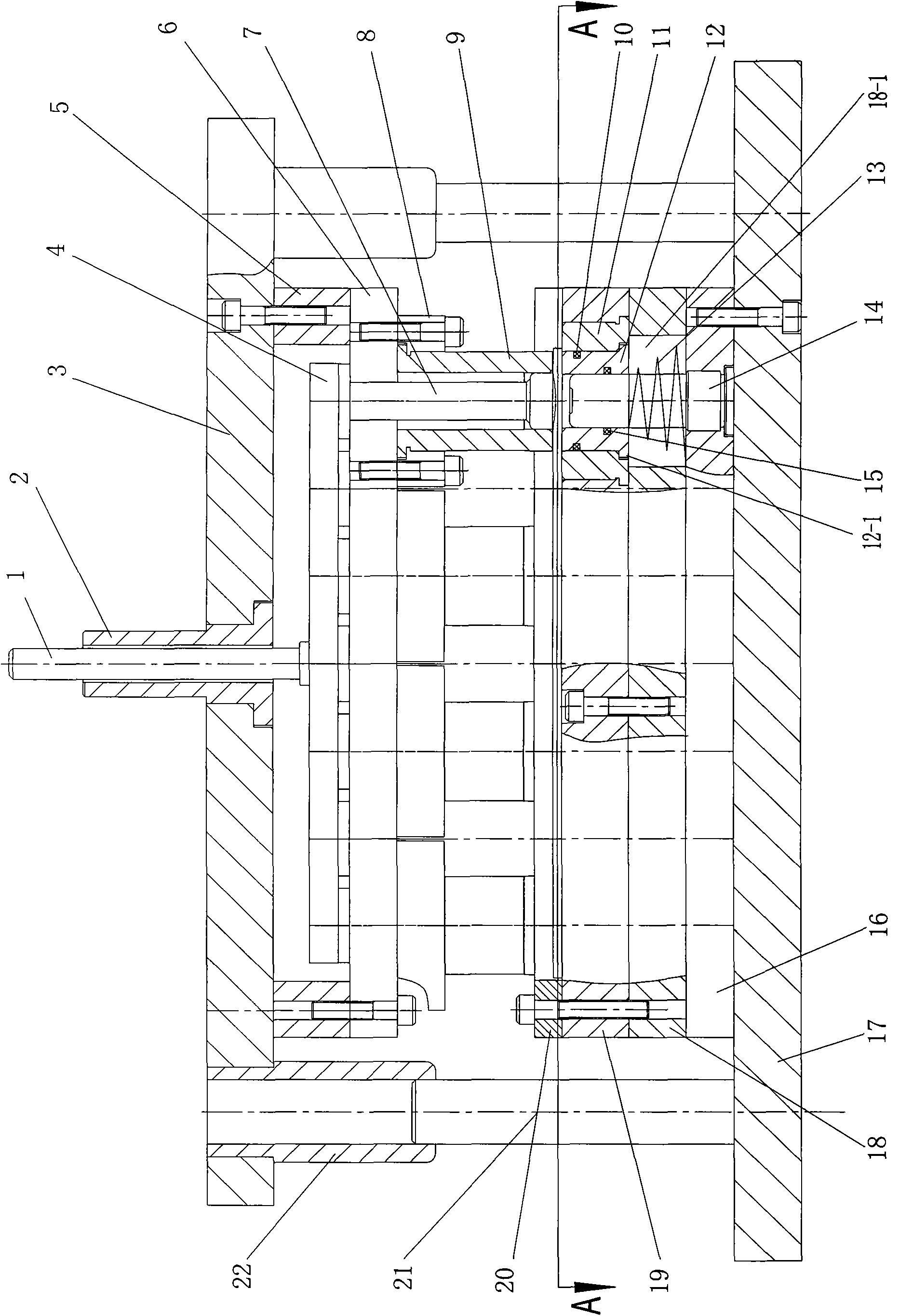

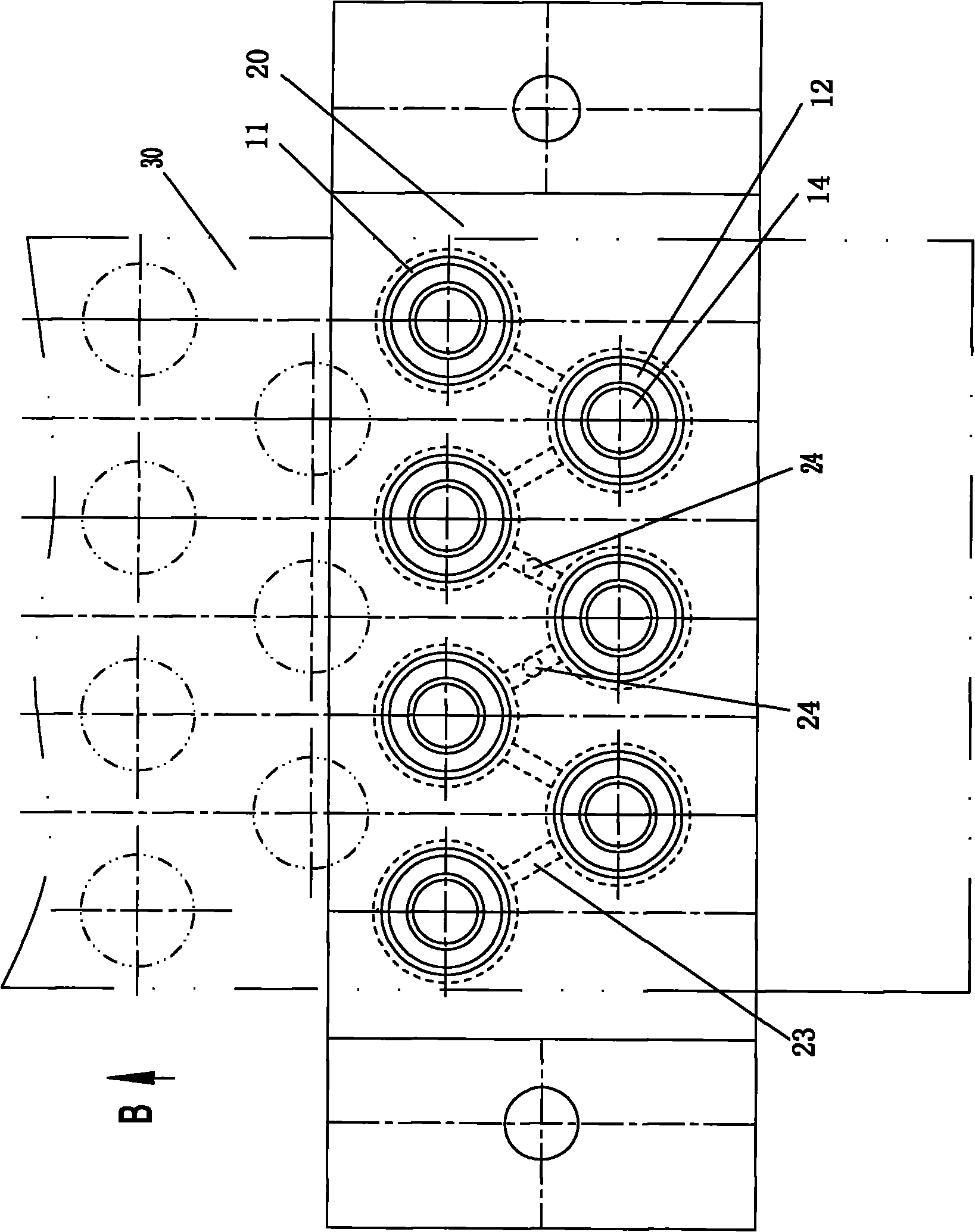

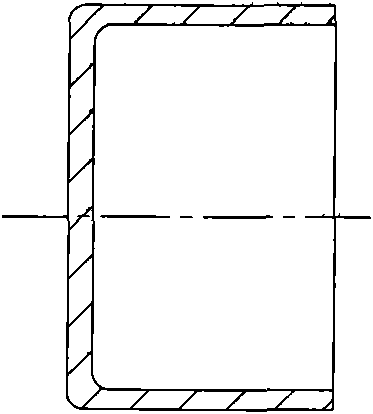

[0017] As shown in the accompanying drawings, the capacitor aluminum shell blanking and deep drawing composite mold includes a lower mold base 17 fixed on the frame and an upper mold base 3 driven by a power mechanism and relatively moving with the lower mold base through guide rails (Fig. The guide rail shown in is a guide post 21 vertically fixed on the lower die base, and a guide sleeve 22 which is vertically fixed on the upper die base and can be slidably matched with the guide post), and several concave holes are vertically fixed on the lower die base. Die 11, a punch 14 is vertically fixed in the center of the cavity of each die, and several concave-convex dies that are vertically suspended downwards and are respectively matched with the die and punch one by one are fixed on the upper die. 9 (it can be seen in the figure: the punch holder 16, the lower backing plate 18, the die holder 19 and the lower die cover 20 are fixed sequentially from bottom to top on the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com