3-freedom-degree wheel clearance detection platform

A detection platform and degree of freedom technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as complex structures, car accidents, and harsh working environments, and achieve the effects of simple and compact structure, intelligent measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific content and working principle of the present invention will be further described below according to the embodiments shown in the accompanying drawings.

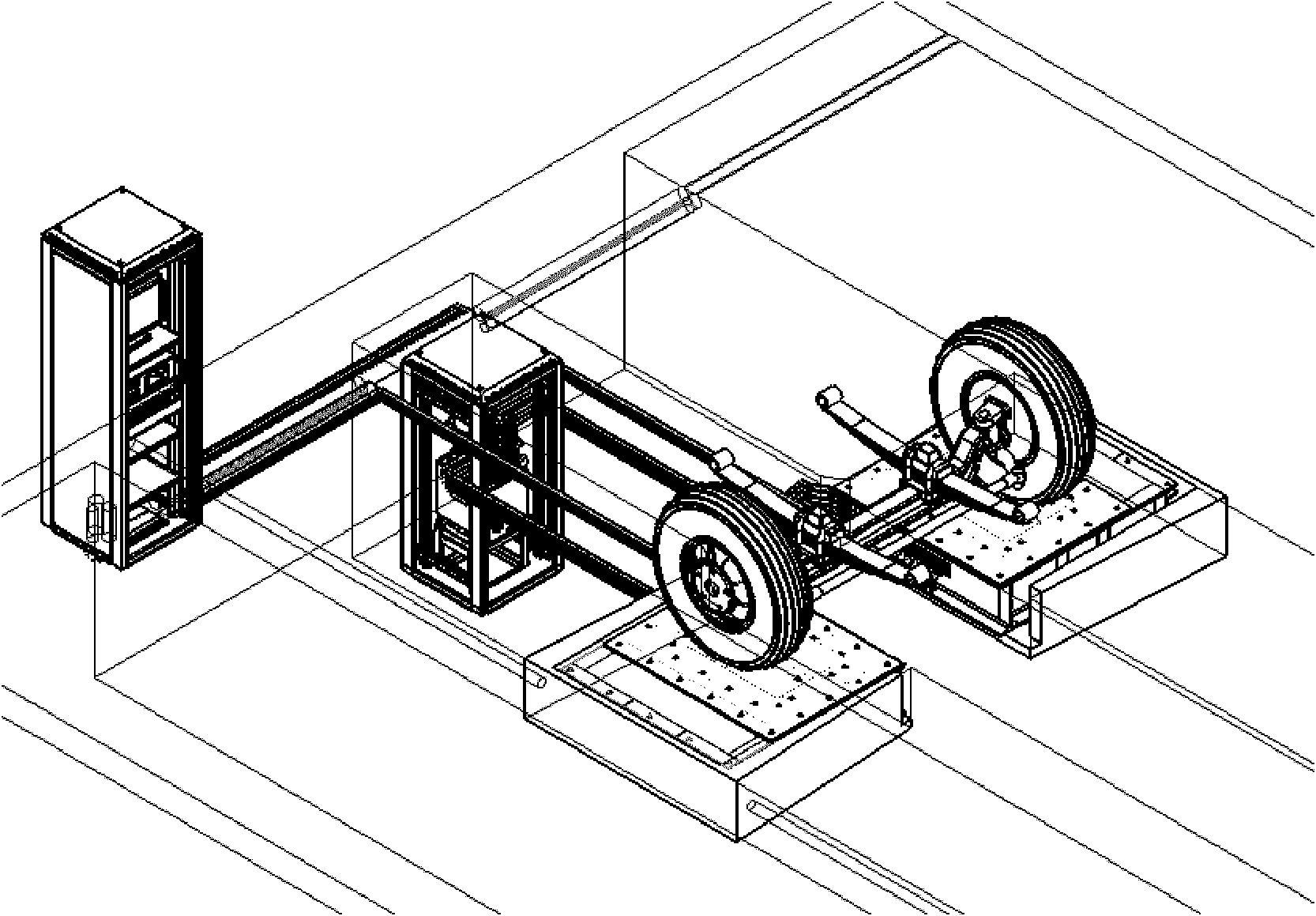

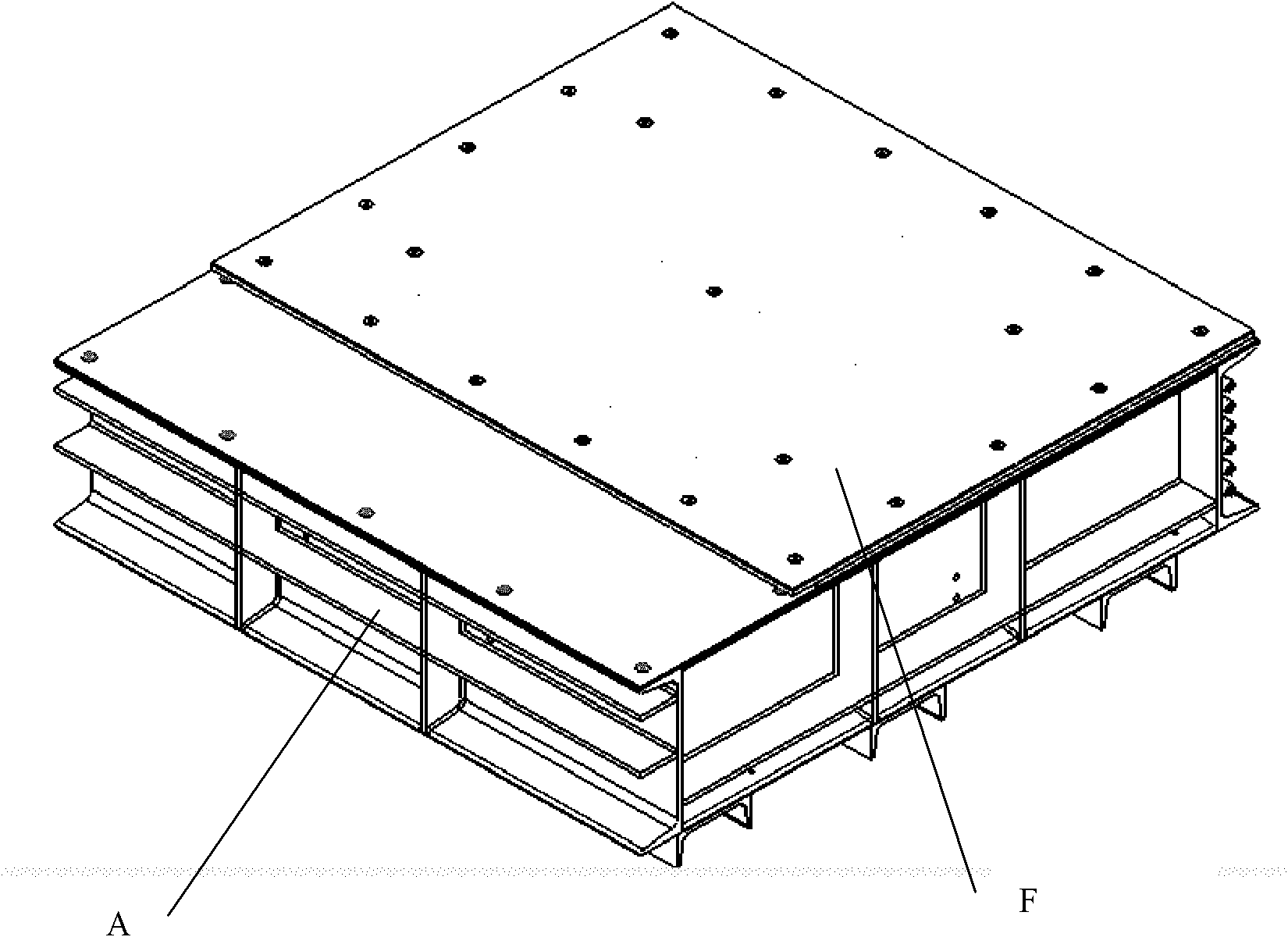

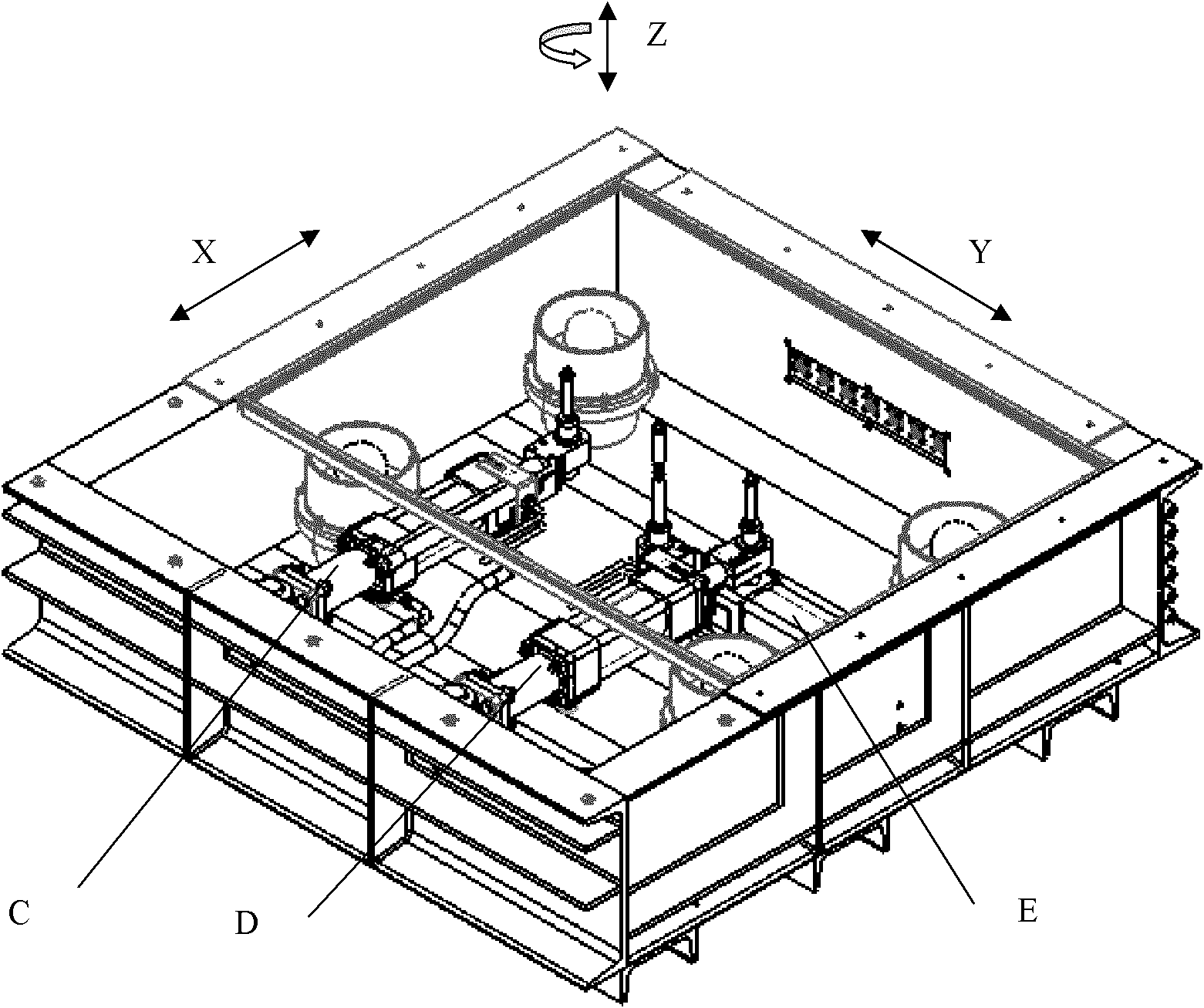

[0046] A three-degree-of-freedom wheel clearance detection platform according to the present invention is mainly composed of two symmetrical wheel clearance detection platforms, left and right, and each detection platform includes: a wheel clearance frame assembly A, an upper plate skeleton assembly B, Rear double-piston-rod cylinder assembly C, rear double-piston-rod cylinder assembly D, longitudinal single-piston-rod cylinder assembly E, upper deck assembly F.

[0047] The wheel gap frame assembly A is fixed in the secondary pouring cement of the vehicle inspection ditch, that is, on the foundation; The ball 5 slides upward, and the upper deck skeleton 18 of the upper deck skeleton assembly B is connected with the three oil cylinder assemblies through the piston rod ear ring pin 35, and the telescopic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com