Long-tail type rifle grenade

A gun grenade and bomb tail technology, which is applied in the direction of warheads, ammunition, weapon accessories, etc., can solve the problems of small initial velocity, large volume, low energy utilization rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

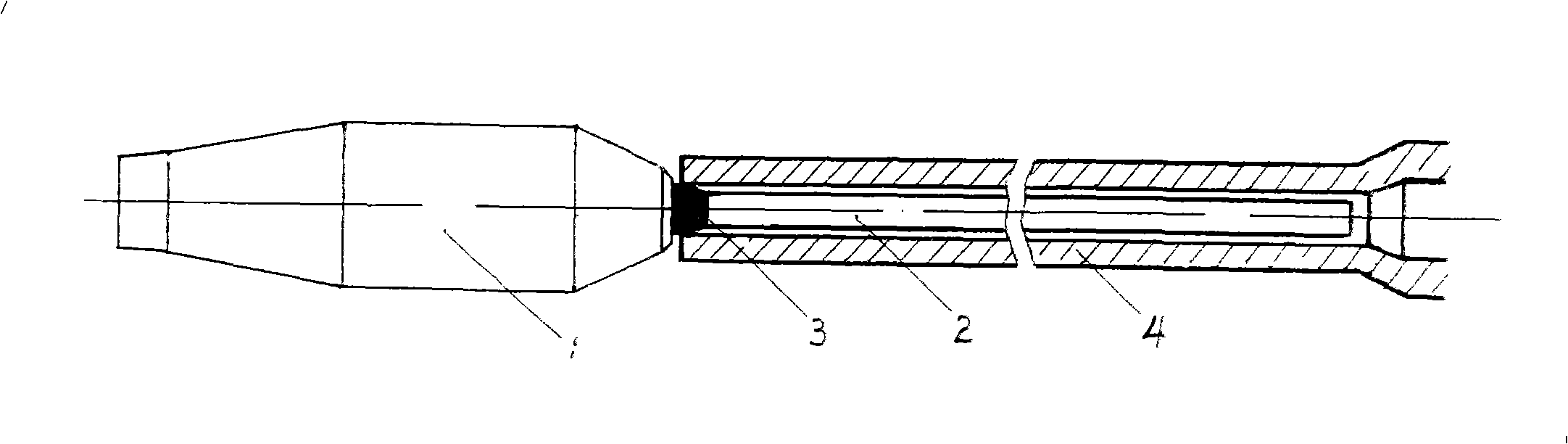

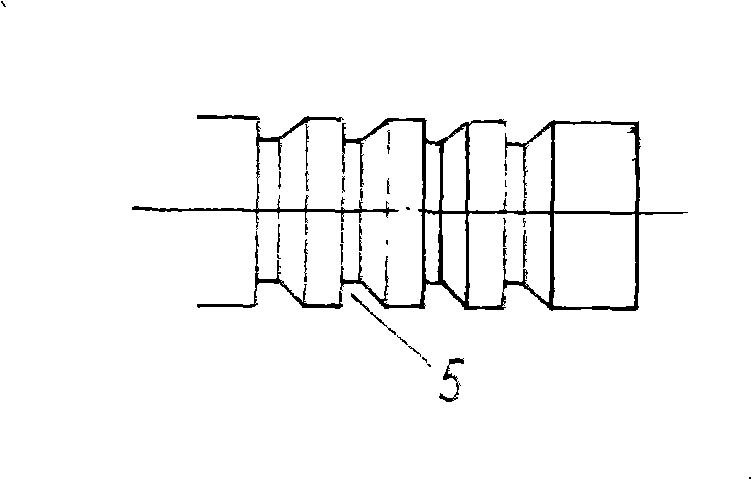

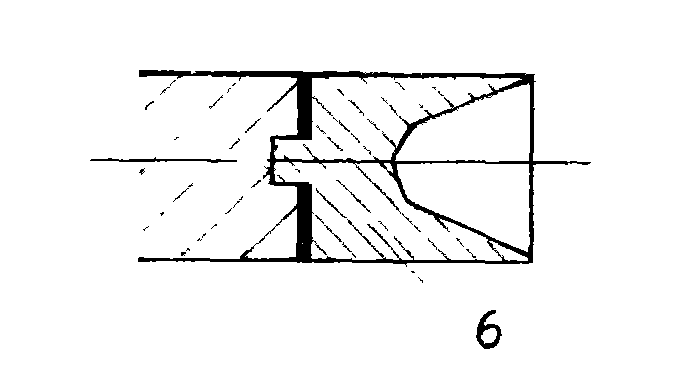

[0020] figure 1 Among them, the bullet tail (2) adopts a steel pipe or an aluminum alloy rod, and the diameter is slightly smaller than the caliber of the gun, and is connected with the rifle grenade warhead (1) in a threaded or inserted manner. A circle of elastic paint layer (3) (material is rubber or plastics) is coated with a circle of elastic paint layer (3) (material is rubber or plastics) to fix rifle grenade on the shell tail outer surface behind the joint. There is a sealing device at the end of the bullet tail, and the structure of the sealing device can be a "vortex groove" structure or an "expansion bowl" structure, or a combined structure of a "vortex groove" and an "expansion bowl". Use gun propellant with a thicker burning layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com