Cooling water pipe for electric vehicle and production technology thereof

A technology for cooling water pipes and electric vehicles, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc. It can solve problems such as poor product quality, many processes, and complicated production processes, and achieve simplified production processes and good product quality , strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

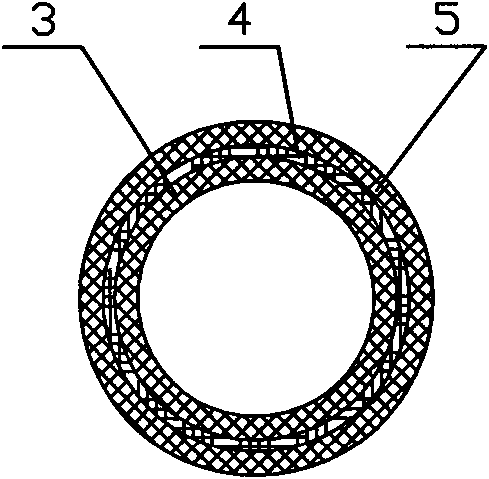

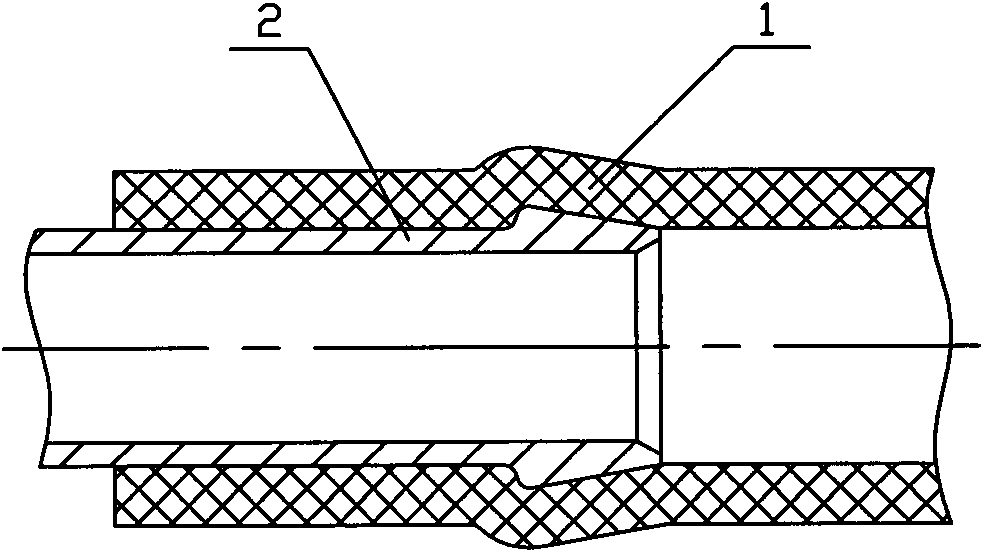

[0050] Depend on figure 1 , figure 2 The shown schematic diagram of the structure of the cooling water pipe of the present invention for electric vehicles shows that it includes a cooling water pipe 1 made of rubber. 5. The inner and outer tube rubber layers include the following components:

[0051] EPDM 100 parts by weight

[0052] Peroxide vulcanizing agent 5 parts by weight

[0053] 2.5 parts by weight of crosslinking agent TAIC

[0054] Antiaging agent RD 2 parts by weight

[0055] Reinforcing agent 550 80 parts by weight

[0056] Plasticizer 2250 12 parts by weight

[0057]1.5 parts by weight of stearic acid

[0058] Total: 203 parts by weight

[0059] The fiber thread reinforcement layer 4 is an aramid thread layer.

[0060] One end of the cooling water pipe 1 has a quick joint 2 made of plastic, and the quick joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com