Submerged pump with spiral labyrinth seal device

A labyrinth seal and screw seal technology, applied in pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as affecting submersible pumps and leaking liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

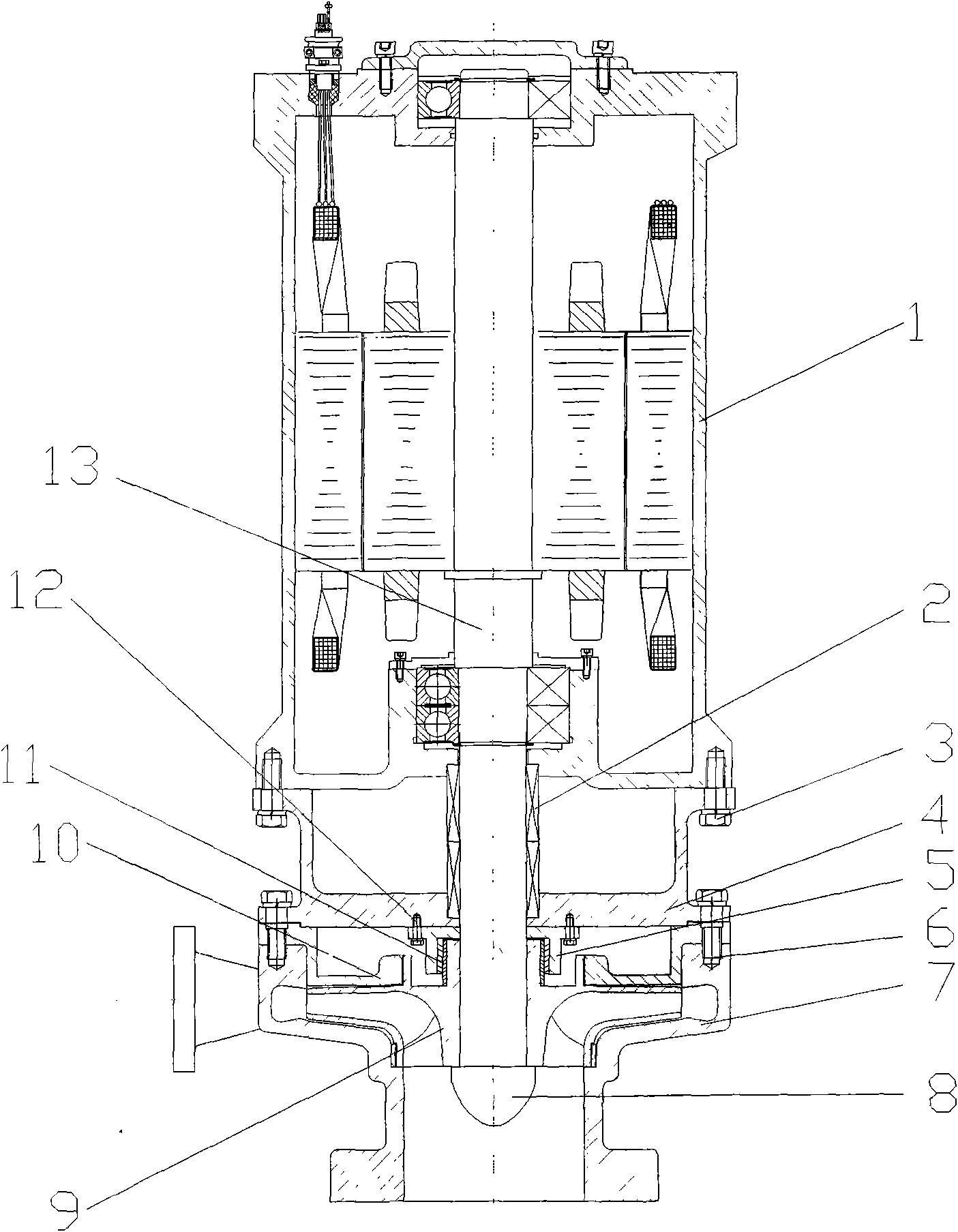

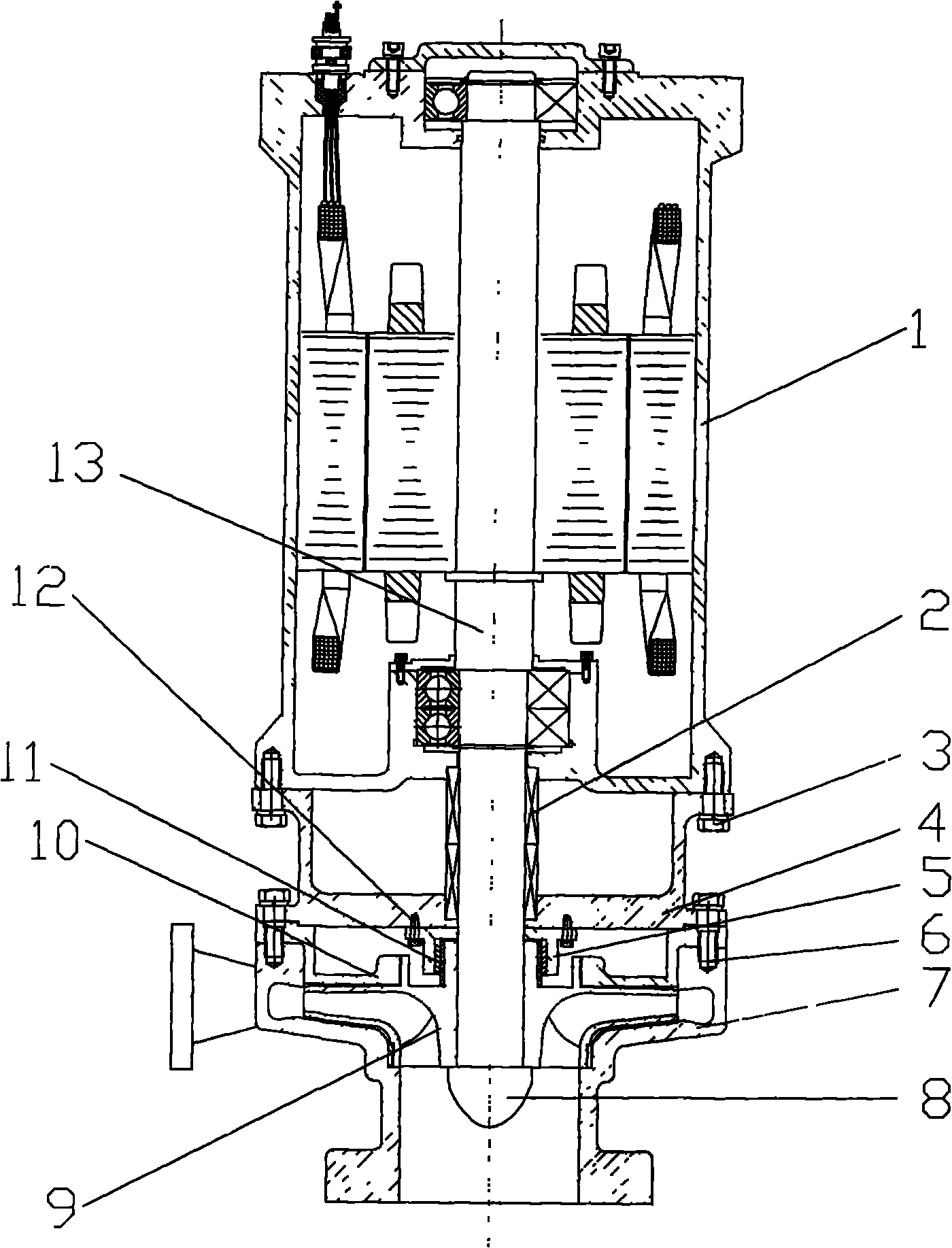

[0008] Such as figure 1 As shown, the impeller 9 is fixed on the motor shaft 13 through the impeller nut 8, and a pump cover 10 is arranged above the impeller 9. The pump cover 10 is fixed with the pump body 7 through the connecting bolt 6. The pump cover 10 and the impeller 9 rear cover The first seal is formed between the seal rings at the plate to prevent the leakage of the conveying medium in the pump body 7. A right-handed spiral seal ring 11 is provided on the back of the impeller 9 close to the motor shaft 13, and a pass through impeller 9 is provided above the impeller 9. The connecting bolt 12 is fixed on the left-handed sealing ring 5 on the sealing chamber 4, and the right-handed sealing ring 11 and the left-handed sealing ring 5 form a labyrinth sealing device to form a second seal to prevent further leakage of the conveying medium in the pump body 7. The sealing chamber 4 is equipped with a mechanical seal 2 to form a third sealing device to ensure that the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com