High-low temperature cycling four-layer separation decoking method during biomass gasification process

A high-low temperature circulation and biomass technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems that the purification effect can only barely meet the requirements of internal combustion engines, difficult realization, secondary pollution, etc., and achieve easy implementation and high utilization rate , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A high-low temperature cycle four-layer separation decoking method in the process of biomass gasification, comprising the following steps:

[0021] (1) Put the material into the fuel barrel of the gasifier, and at the same time ignite it from the bottom of the gasifier and let in air.

[0022] (2) After the air is heated to 1000-1200°C when passing through the ash layer, it enters the oxidation zone in the gasifier.

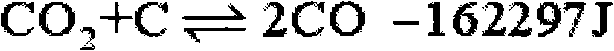

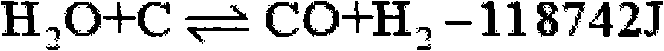

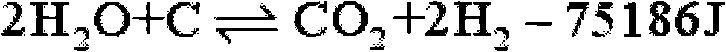

[0023] (3) In the oxidation zone, the charcoal generated after burning with fuel undergoes a combustion reaction at a temperature of 1000-1200 ° C to generate carbon monoxide and carbon dioxide, and release heat at the same time. Due to oxygen-limited combustion, the supply of oxygen is insufficient, so the incomplete combustion reaction and complete combustion reaction occur simultaneously. The reaction heat generated in this reaction process provides a heat source for the subsequent reduction reaction in the reduction zone, cracking and drying of materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com