Process for producing ammonia from urea used for denitration of boiler smoke and system thereof

A technology for boiler flue gas and urea, which is applied in the field of urea-to-ammonia production process and its system, can solve the problem of high operating costs, and achieve the effects of reducing operating costs, safe process operation, and stable temperature conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

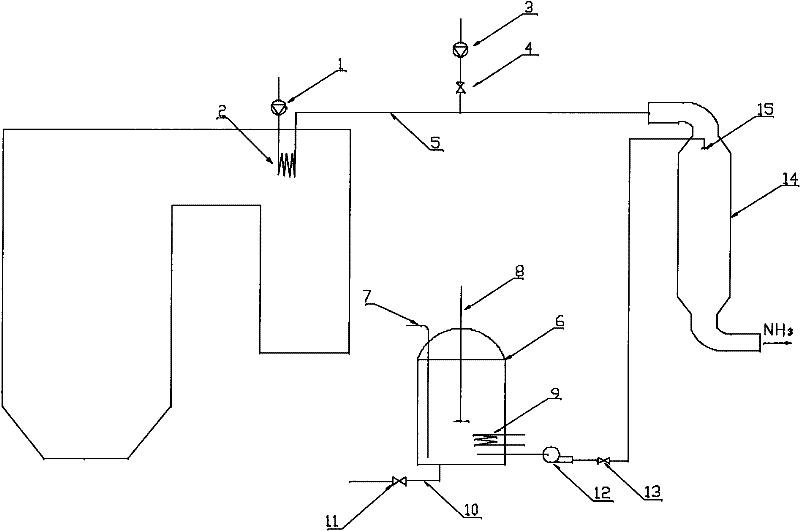

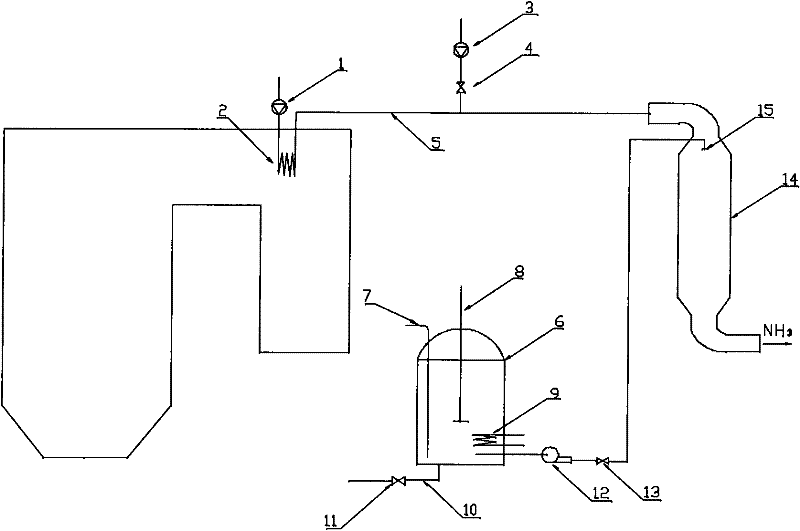

[0030] figure 1 Shown is the schematic diagram of the system used in the urea ammonia production process for boiler flue gas denitrification of the present invention, including: a urea solution supply system, a heat source system and a decomposition chamber connected to the urea solution supply system and the heat source system through pipelines respectively 14.

[0031] Wherein, the urea solution supply system includes a storage tank 6, a feeding pipe 7 inserted into the storage tank 6 from the top of the storage tank 6, an agitator 8 and a heater 9 arranged inside the storage tank 6, The blowdown pipeline 10 that is arranged at the bottom of the storage tank 6 and the blowdown valve 11 connected with the blowdown pipeline 10, and the feed pump 12 that is arranged on the pipeline that is used to connect the storage tank 6 and the decomposition chamber 14 and outlet valve 13.

[0032] The top of the decomposition chamber 14 is provided with a nozzle 15 .

[0033] The heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com