Processing method of low-salt ferment local-flavor fresh hot-pepper sauce

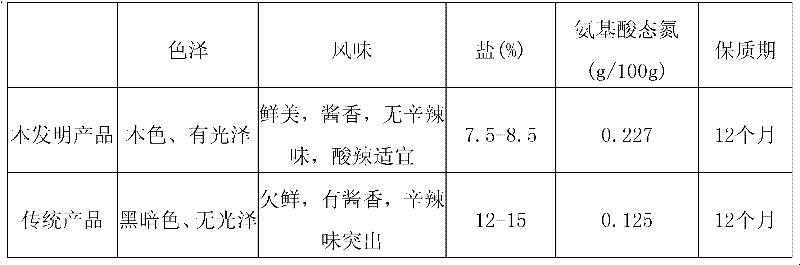

A processing method and technology of fermented flavor, applied in the processing field of low-salt fermented flavor fresh chili sauce, can solve problems such as difficult production management control of chili sauce, difficult control of fermentation conditions, difficulty in ensuring sanitation, etc., so as to speed up the cycle of equipment and capital , solve color problems and quality and safety problems, and appetizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 35kg of wheat, 45kg of oats and 20kg of soybeans as raw materials, soak them in 230kg of tap water for 8 hours, take them out and drain them, cook them at 110°C for 18 minutes, and cool them down naturally to make the water content of the cooked materials reach 135%. 235kg; The raw material after cooling is equally divided in two fermenting containers, admixed in a container is the rhizopus powder of 0.15% of raw material weight in the container, and is admixed in another container and is the rhizopus powder of 0.15% of raw material weight in the container, After mixing evenly, stack and keep warm at 26°C for 12 hours; put the heat-preserved raw materials in the two fermentation containers on the koji plate with a stacking thickness of 3 cm, and keep them fermented at 26°C. After 46 hours of normal fermentation, the formed koji surface The water evaporates, and the koji weighs 210kg at this time; 14.7kg of salt is added to the koji to make koji, and it is cooked at 4...

Embodiment 2

[0030]Take 40kg of raw materials wheat, 35kg of oats and 25kg of soybeans, soak them in 250kg of tap water for 9 hours, take them out and drain them, cook them at 115°C for 19 minutes, and then cool them naturally to make the water content of the cooked materials reach 140%. 240kg; divide the cooled raw materials equally into two fermentation containers, mix in the rhizopus powder and aspergillus oryzae powder which are 0.18% of the raw material weight in the container respectively, and add the weight of rhizopus powder and aspergillus oryzae powder in equal amounts, and stir evenly , stacked and kept at 28°C for 10 hours; put the heat-preserved raw materials in the two fermentation containers on the bent plate, with a stacking thickness of 3 cm, and kept them fermented at 28°C. After 48 hours of fermentation, the water on the surface of the formed koji was evaporated. The weight of the koji is 220kg; add 16.5kg of salt to the koji to form the fermented rice, heat it at 45°C an...

Embodiment 3

[0035] Take 45kg of raw wheat, 40kg of oats and 15kg of soybeans, soak them in 270kg of tap water for 10 hours, take them out and drain them, cook them at 120°C for 20 minutes, and cool them down naturally to make the water content of the cooked materials reach 145%. 245kg;; Divide the cooled raw materials into two fermentation containers, mix them into the Rhizopus powder and Aspergillus oryzae powder which are 0.2% of the weight of the raw materials in the container respectively, add the Rhizopus powder and Aspergillus oryzae powder in equal weight, and mix evenly Finally, stack and keep warm at 30°C for 12 hours; put the heat-preserved raw materials in the two fermentation containers on the bent plate, with a stacking thickness of 3cm, and heat and ferment at 30°C. After 50 hours of fermentation, the water on the surface of the formed bent blank is evaporated. The koji weighed 220kg at the time; 17.6kg of salt was added to the koji to make the koji, and it was cooked at 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com