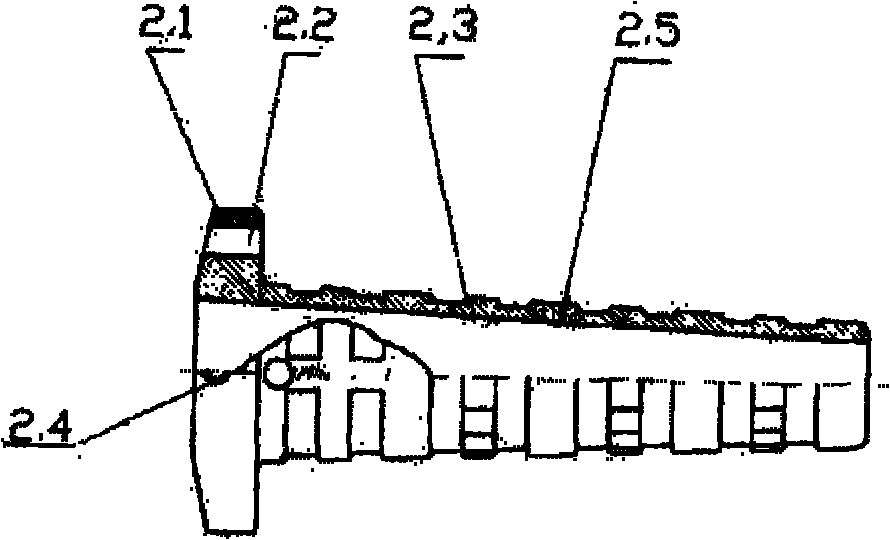

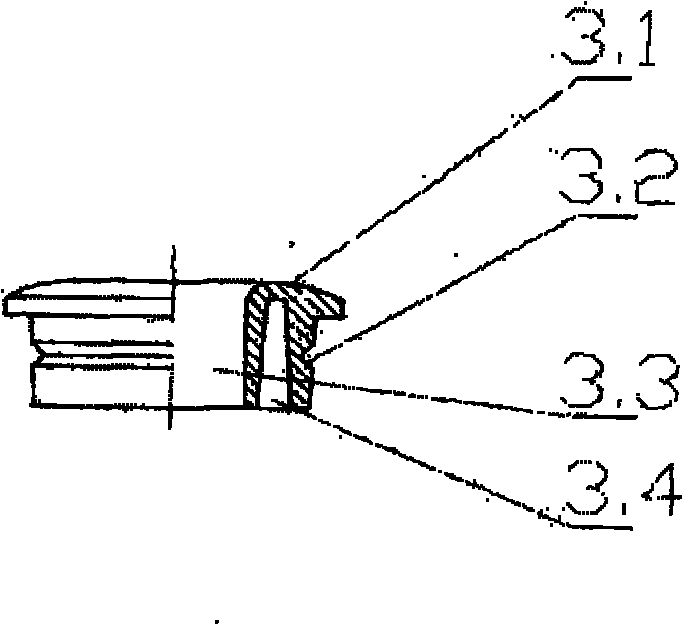

Taper type anti-skidding strain clamp

A tension clamp, anti-skid technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of poor mechanical properties, plastic aging, reduction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] When installing and using the line, after assembling all the tapered non-slip and strain-resistant clamps as mentioned above, use the wire head or a special tool to align the inner holes of the three claws of the three anti-slip clamps and push them inward to a proper position. Because the endoporus of the conical housing 2 is tapered, the anti-slip clamping line three jaws 5 are displaced to the outside by the elastic force of three even melon springs 7, and the enlarged aperture is convenient for wire insertion. Insert the wire into an appropriate length, then release the wire tensioner, and use the tension of the wire's own weight. At this time, the three non-slip clamping claws 5, due to the action of the push melon spring 4, the three non-slip clamping claws 5 will move outwards, and at this time the anti-slip The inner threads of clamp claw 5 are tightly wrapped to hold the wire, and the greater the pulling force of the wire, due to the taper effect, the greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com