Universal flexible multi-functional coupling

A technology of universal flexibility and couplings, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve problems such as difficult installation, adjustment, high precision requirements, and single use conditions, so as to achieve the goal of not being easily damaged. Large shaft and fatigue torque, time-saving and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

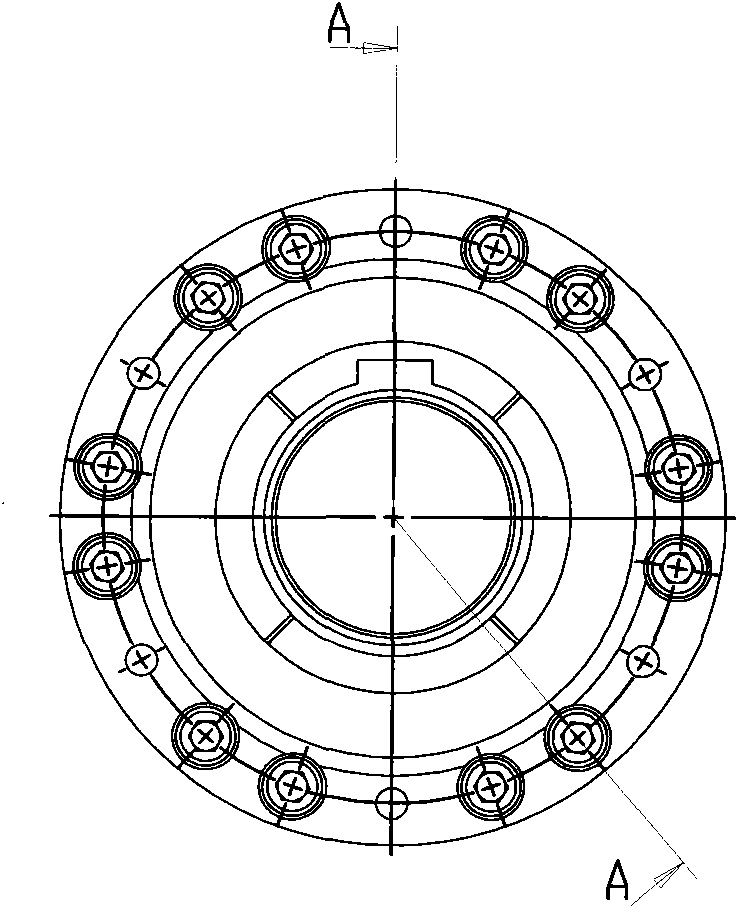

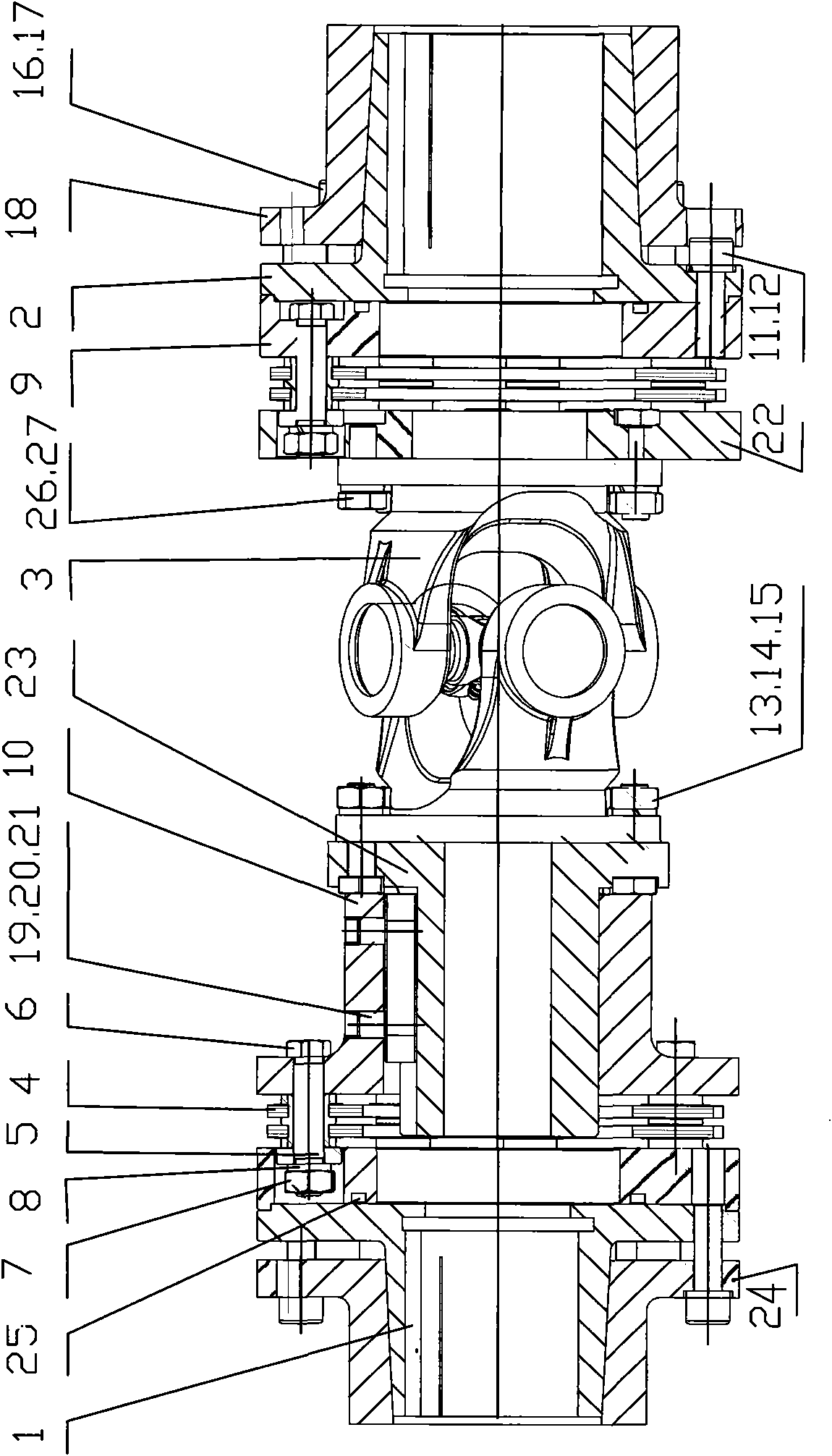

[0021] The shaft coupling of the present invention will be further described in detail below in conjunction with the embodiments.

[0022] Such as figure 1 , 2 , 3, and 4, the shaft coupling of this example is from the passive end tapered sleeve 24 to the active end tapered sleeve 18, followed by the passive end semi-connected sleeve 1, the elastic ring 25, the docking disc I28, and the overlapping film Sheet group 4, slidable adjustable shaft sleeve 10, slidable adjustable mandrel 23, universal joint 3, docking disk II22, overlapping diaphragm group 4, docking disk III9, semi-connected taper sleeve 2 at the driving end. One end of the passive end tapering sleeve 24 with a flange is placed on the cone of the passive end half coupling sleeve 1, and they are fixed by bolts; There is a ring of grooves on one end surface of the sleeve 1 near the inner hole, and an elastic ring 25 is installed in the grooves; the other end of the docking disk I28 and the overlapping diaphragm gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com