Conveying system of digital control processing machine

A conveying system and processing machine technology, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of slow and slow conveying speed of the conveying body 3, and achieve the effect of increasing the allowable rotational speed and increasing the conveying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The advantages and features of the present invention, as well as the methods for realizing them, will be more clearly understood through the accompanying drawings and the embodiments described in detail below.

[0040] Throughout the specification, the same reference signs refer to the same structural elements.

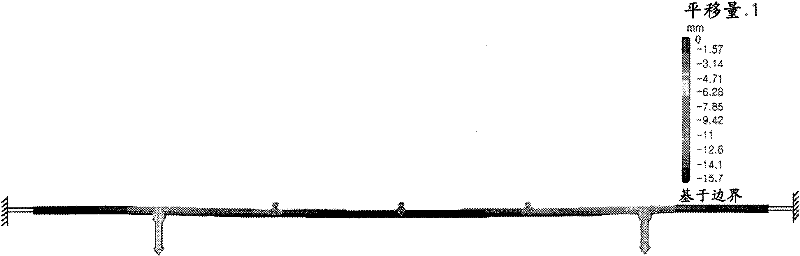

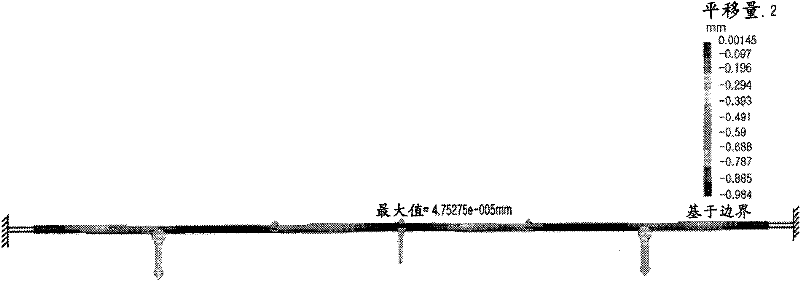

[0041] Below, refer to image 3 and Figure 7A conveying system of a numerically controlled processing machine according to a first embodiment of the present invention will be described.

[0042] In the attached picture image 3 is an exemplary plan view for explaining a conveying system of a numerically controlled processing machine according to a first embodiment of the present invention, Figure 4 yes image 3 An illustration of the X-X line section.

[0043] Such as image 3 and Figure 4 As shown, according to the conveying system of the numerical control processing machine according to the first embodiment of the present invention, the servo motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com