Cyanide-free alkaline copper plating solution and preparation method thereof

A technology of cyanide-free alkaline copper plating and copper plating solution, which is applied in the field of preparation of cyanide-free alkaline copper plating solution and cyanide-free alkaline copper plating solution, and can solve the problem of poor bonding force of the plating layer, affecting the bonding force of the plating layer, and deposition Speed drop and other problems, to achieve the effect of good dispersion ability of plating solution, strong throwing and covering power, strong throwing ability and covering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

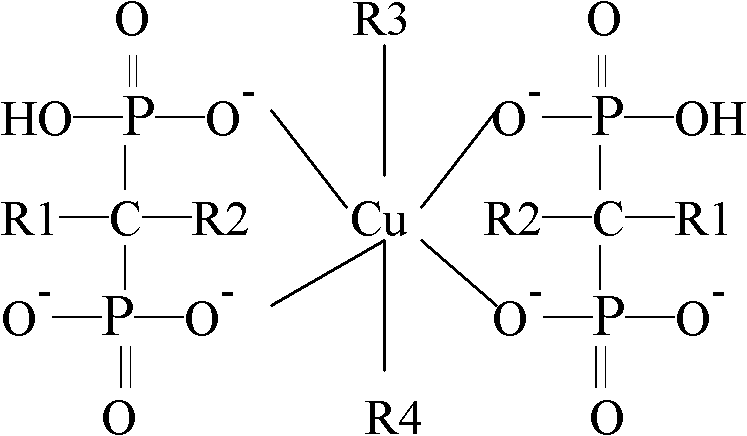

Method used

Image

Examples

Embodiment 1

[0043] Plating solution composition:

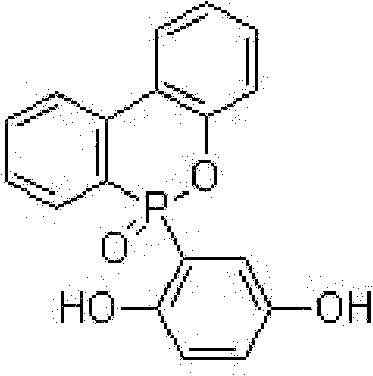

[0044] 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide

[0045] 200g / L

[0046] Copper ion in basic copper carbonate 8g / L

[0047] Potassium hydroxide 20g / L

[0048] Potassium carbonate 30g / L

[0049] Preparation:

[0050] ①. Use distilled water to make basic copper carbonate into a paste; ②. Dissolve the complexing agent with distilled water, and then add potassium hydroxide or sodium hydroxide solution to adjust the pH to 8.0-9.0; ③. Under stirring conditions Next, slowly add solution ① to solution ② to make it fully complexed; ④, dissolve potassium carbonate with distilled water, and gradually add it to solution ③; ⑤, use potassium hydroxide or sodium hydroxide to dissolve the plating solution Adjust the pH value to between 9-10; ⑥, use distilled water to make up the volume before use.

[0051] The cathode current density of the electroplating bath is 0.5A / dm during electroplating 2 , the pH value of the ...

Embodiment 2

[0053] Plating solution composition:

[0054] 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide

[0055] 250g / L

[0056] Copper ion in basic copper carbonate 10g / L

[0057] Potassium hydroxide 30g / L

[0058] Potassium carbonate 35g / L

[0059] Preparation:

[0060] ①Use distilled water to make basic copper carbonate into a paste; ②Dissolve the complexing agent in distilled water, then add potassium hydroxide or sodium hydroxide solution, and adjust the pH to 8.0-9.0; ③Under stirring conditions, mix Add solution ① slowly to solution ② to make it fully complexed; ④ dissolve potassium carbonate with distilled water and add it to solution ③; ⑤ adjust the pH value of the plating solution to 9 with potassium hydroxide or sodium hydroxide again Between -10; ⑥It can be used after making up to volume with distilled water.

[0061] Electroplating copper bath cathode current density 1.0A / dm 2 , the pH value of the plating solution is 9.5, and the temperature o...

Embodiment 3

[0063] Plating solution composition:

[0064] 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide

[0065] 300g / L

[0066] Copper ions in copper nitrate 12g / L

[0067] Potassium hydroxide 30g / L

[0068] Potassium carbonate 40g / L

[0069] Preparation method:

[0070] ①Use distilled water to make basic copper carbonate into a paste; ②Use distilled water to dissolve 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide , then add potassium hydroxide or sodium hydroxide solution, and adjust the pH to between 8.0-9.0; ③ under stirring conditions, slowly add solution ① to solution ② to make it fully complexed; ④ use potassium carbonate Dissolve in distilled water and add to the solution ③ successively; ⑤ Adjust the pH value of the plating solution to 9-10 with potassium hydroxide or sodium hydroxide again;

[0071] Electroplating copper bath cathode current density 1.5A / dm 2 , the pH value of the plating solution is 10.0, and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com