Niobate or tantalite fluorescent material used for white light LED and preparation method thereof

A fluorescent material, niobate technology, applied in the field of fluorescent materials, can solve the problem of few research reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

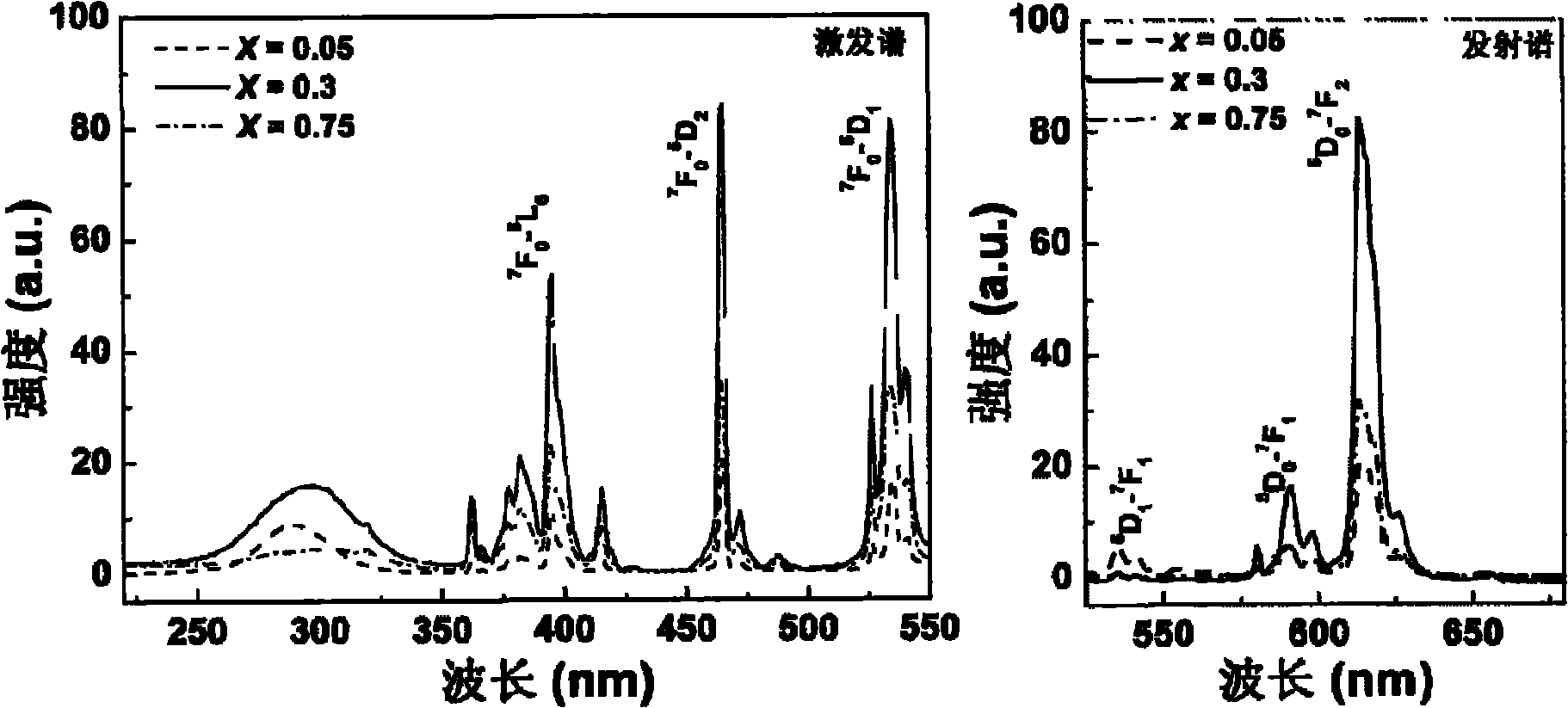

[0133] Raw material CaCO 3 、Eu 2 o 3 , Nb 2 o 5 According to Ca 2 EuNbO 6 The stoichiometric ratio was weighed, mixed evenly in a mortar, put into a corundum crucible with a cover and pre-fired at 625°C for 24h. The obtained powder is fully ground and then fired at 1000°C, 1200°C, and 1500°C for 24 hours respectively. Made into pure Ca 2 EuNbO 6 fluorescent material. see test results figure 1 .

Embodiment 2

[0135] Raw material CaCO 3 、Eu 2 o 3 , Nb 2 o 5 According to Ca 2 EuNbO 6 The stoichiometric ratio was weighed, mixed evenly in a mortar, put into a corundum crucible with a cover, and pre-fired in a hydrogen atmosphere furnace at 625°C for 24h. The obtained powders were fully ground and then fired at 1700°C for 24 hours respectively. Made of pure Ca2EuNbO6 fluorescent material. Test result is comparable with embodiment 1.

Embodiment 3

[0137] Raw material CaCO 3 、Eu 2 o 3 , Nb 2 o 5 According to Ca 2 EuNbO 6 The stoichiometric ratio was weighed, mixed evenly in a mortar, put into a corundum crucible with a cover, and pre-fired in an oxygen atmosphere furnace at 625°C for 24h. The obtained powders were fully ground and then fired at 1300°C for 24 hours respectively. Made into pure Ca 2 EuNbO 6 fluorescent material. Test result is comparable with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com