Preparation method for synthesizing isobornyl acetate by esterification of camphene and acetic acid

A technology for the synthesis of isobornyl acetate, which is applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., to achieve the effects of high conversion rate, high activity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

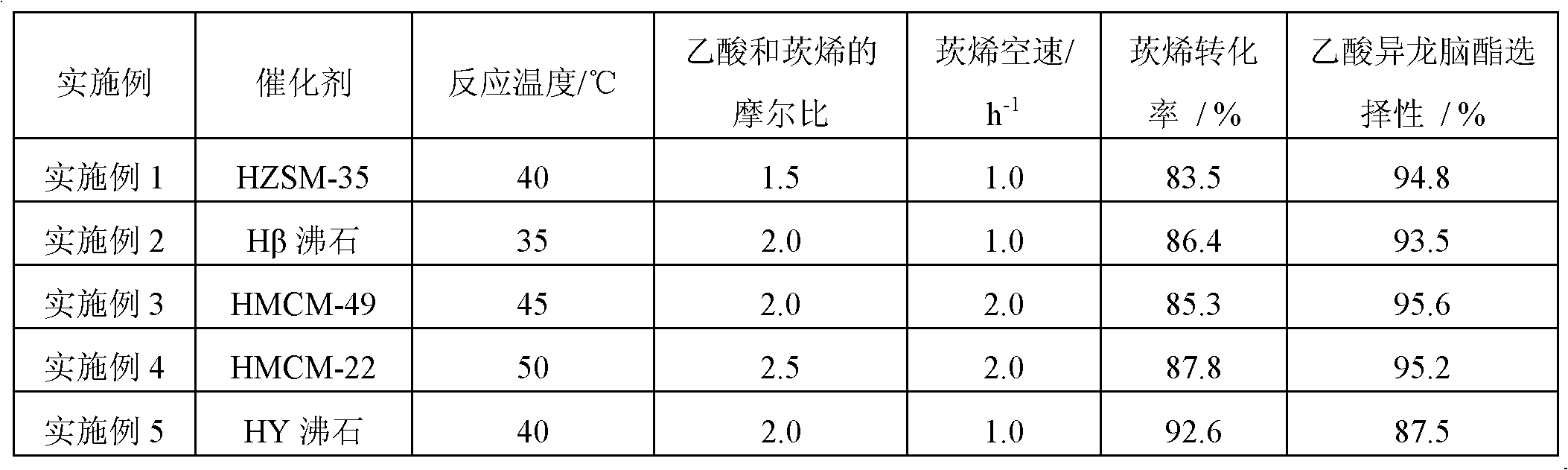

[0013] 100 grams of the synthesized molecular sieve catalysts were respectively loaded into a fixed-bed tubular reactor, and amphene and acetic acid raw materials were injected into the reactor in a certain proportion with a metering pump to carry out normal pressure reaction. The specific reaction conditions and reaction results are shown in Table 1.

[0014] Table 1

[0015]

Embodiment 6~10

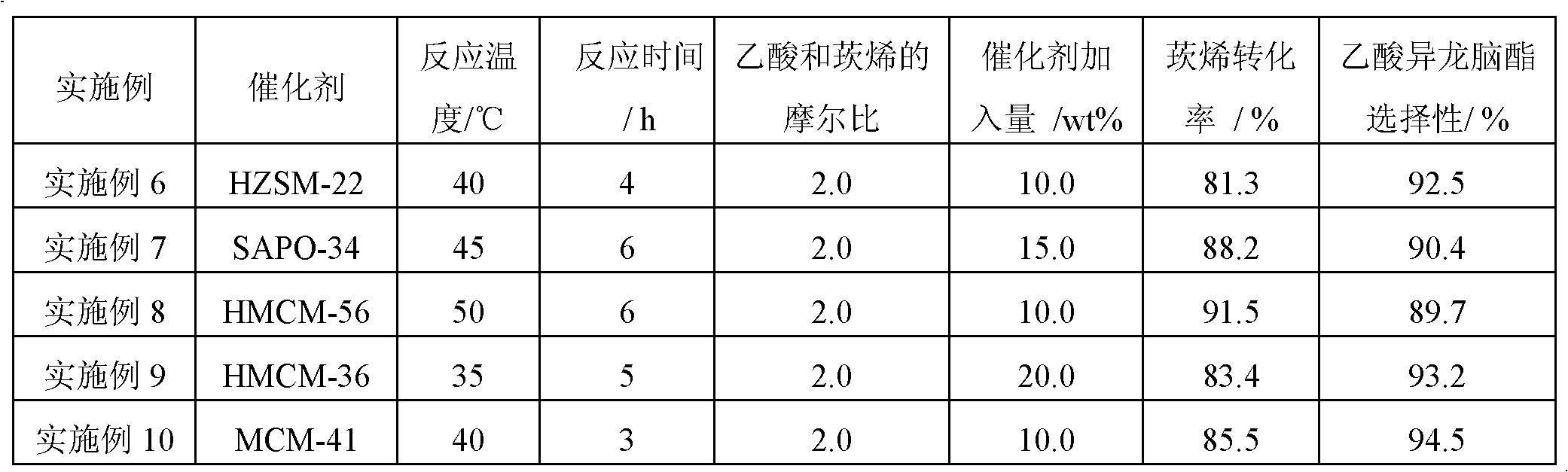

[0017] In 500 milliliters of stainless steel stirred reactors, respectively add 300 grams of mixed raw materials and a certain amount of catalysts (based on the reaction raw materials) by a certain acetic acid / amphene mol ratio, then heat up and carry out normal pressure reaction, specific reaction conditions and The reaction results are shown in Table 2.

[0018] Table 2

[0019]

[0020] Can find out from above-mentioned table 1, table 2: owing to having selected highly active catalyzer, the selectivity of the isobornyl acetate that preparation method of the present invention makes is up to 95.6%, and the camphene conversion rate is up to 92.6%, and the The preparation method has mild reaction conditions and is environmentally friendly, and can be widely used in the industrial synthesis of isobornyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com