Combined welding machine tool box

A toolbox and combined technology, used in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficiency of the number of welding machines, messy stacking of welding machines on site, and reduced production efficiency, etc. Clean construction site and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

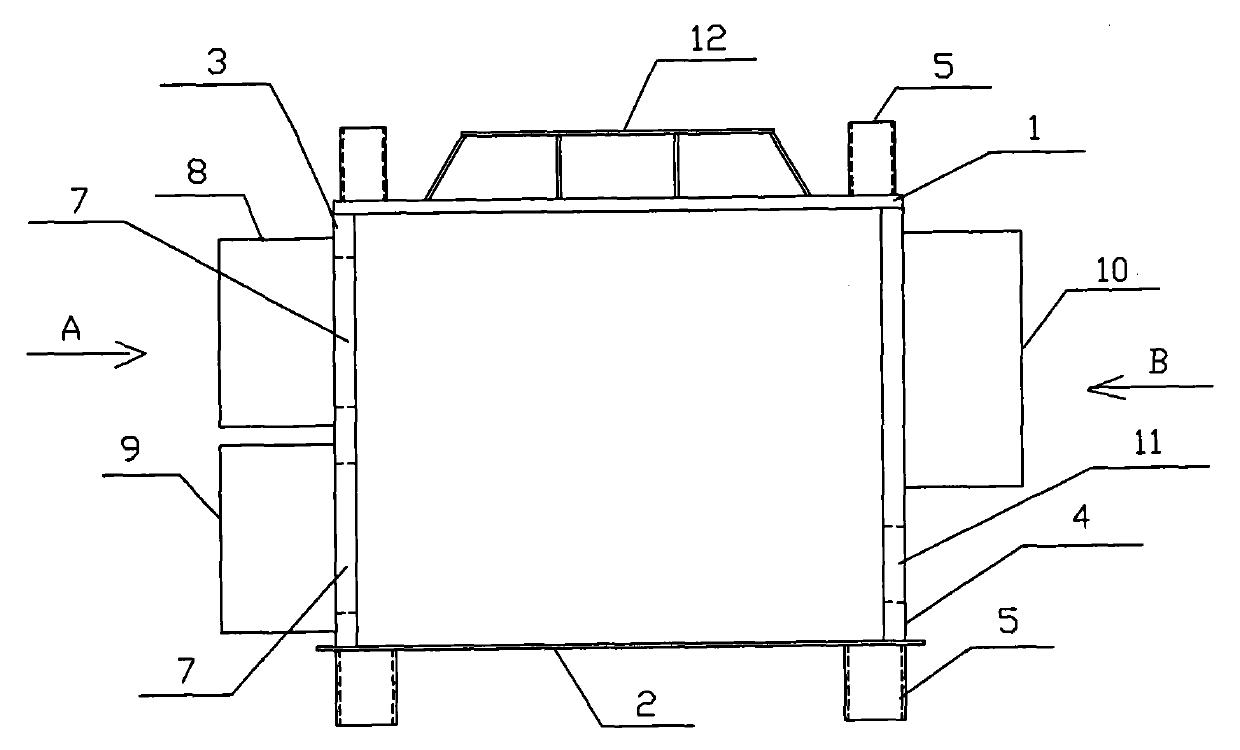

[0013] like figure 1 , figure 2 and image 3 Shown is an embodiment of the combined welding machine toolbox of the present invention, comprising a top plate 1, a bottom plate 2, a left side plate 3 and a right side plate 4 are longitudinally provided between the top plate 1 and the bottom plate 2, the top plate 1, the bottom plate 2 and the Two side plates form a three-dimensional frame, and the upper surface and the lower surface of the three-dimensional frame are connected with a plurality of supporting feet 5, and the plurality of supporting feet 5 are evenly arranged on four end points of the three-dimensional frame. The upper surface and the lower surface are all connected with four supporting feet 5, and the four supporting feet 5 are placed on the four end points of the three-dimensional frame, and the two ends of the outer walls of the left side plate 3 and the right side plate 4 are connected with A plurality of straight ladders 6, the plurality of straight ladders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com