Paint spraying machine for inner wall of steel pipe

A technology for the inner wall of a steel pipe and a spraying machine, which is applied in the direction of coating, a device for coating liquid on the surface, etc., can solve the problems of complicated operation process, environmental pollution and high cost, and achieve simple operation, paint saving, and low spraying cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe in further detail below in conjunction with accompanying drawing and embodiment of the present invention:

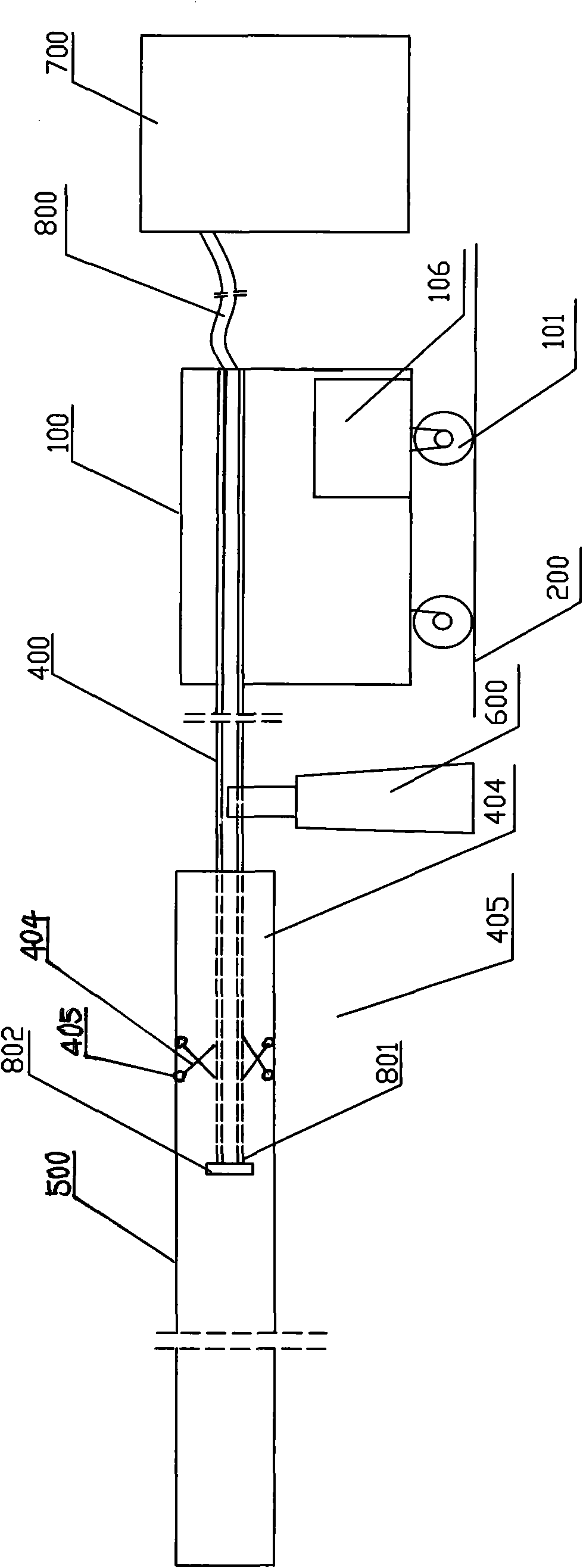

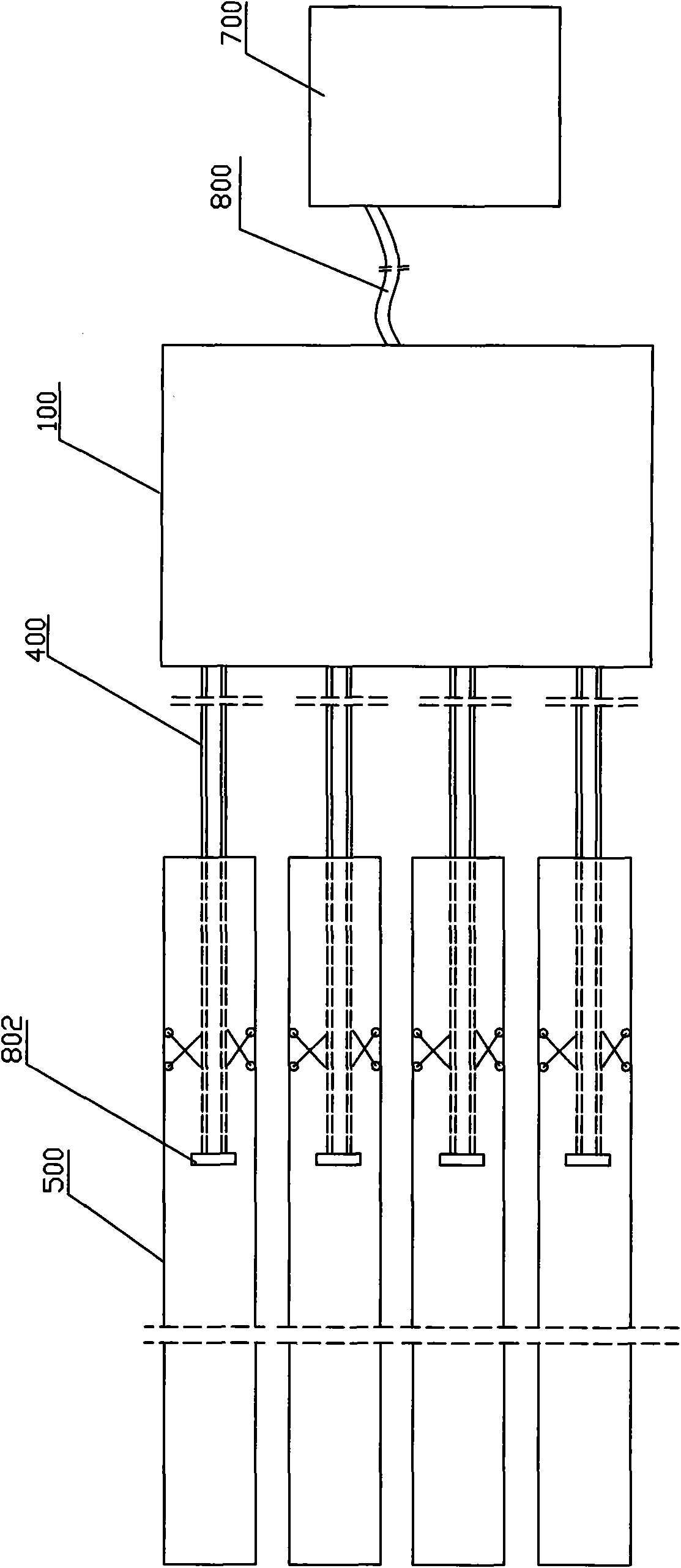

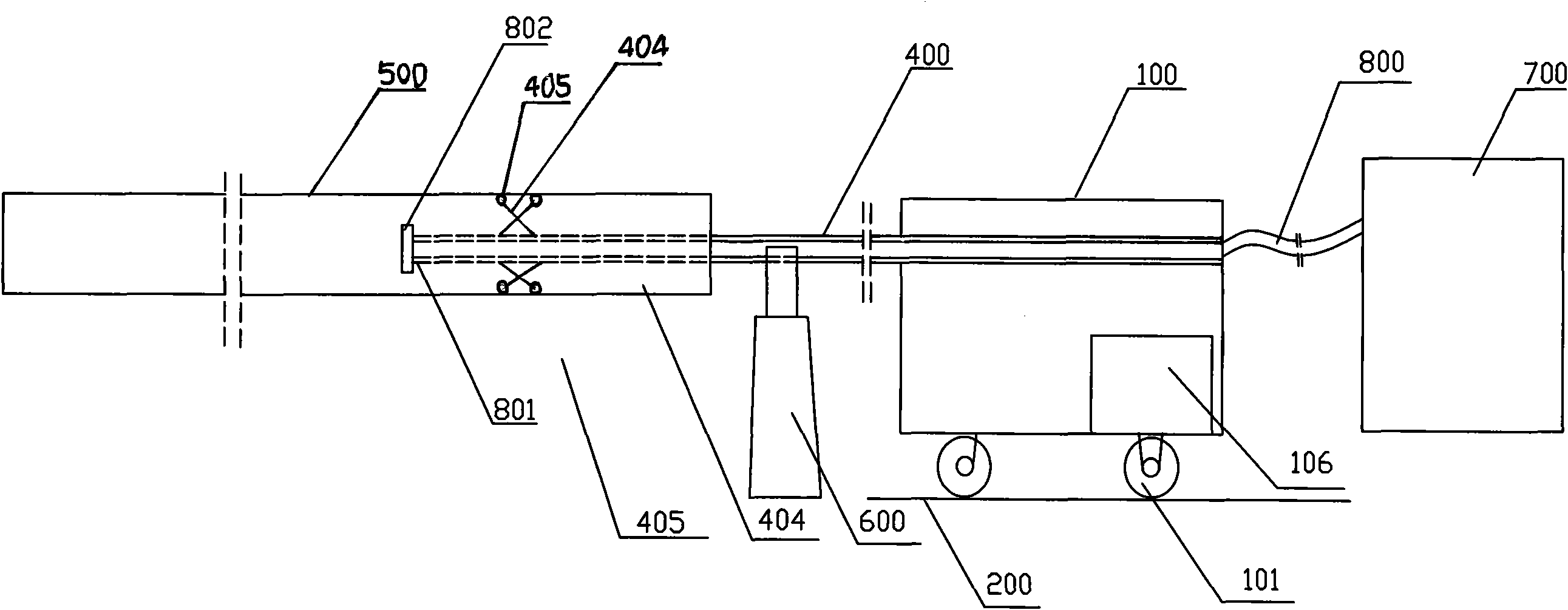

[0015] figure 1 A schematic diagram of an embodiment of a steel pipe inner wall paint spraying machine of the present invention is shown. like figure 1 As shown, a trolley 100 is provided on the track 200 , the bottom of the trolley 100 has wheels 101 , and the trolley 100 can slide on the track 200 . The trolley 100 is provided with a drive motor 106 , which is connected to the wheels 101 through gears. Starting the drive motor 106 can drive the wheels 101 to rotate, and then drive the trolley 100 to slide on the track 200 . Four slender straight pipes 400 are fixed on the trolley 100, and extend out of the trolley 100 and stretch forward. A paint nozzle 802 is installed on the front end of each straight pipe 400. The straight pipe 400 is hollow and has a A paint conveying pipe 800 for conveying paint, one end of the paint conveying pipe 800 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com