Twisted carbon fibre composite core lead splicing sleeve

A composite core and carbon fiber technology, applied in the direction of connection contact materials, multi-core cable end parts, overhead line/cable equipment, etc., can solve the problems that have not yet reached the ideal level, can not meet the use requirements, etc., to achieve convenient installation, Smooth ride and strong grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

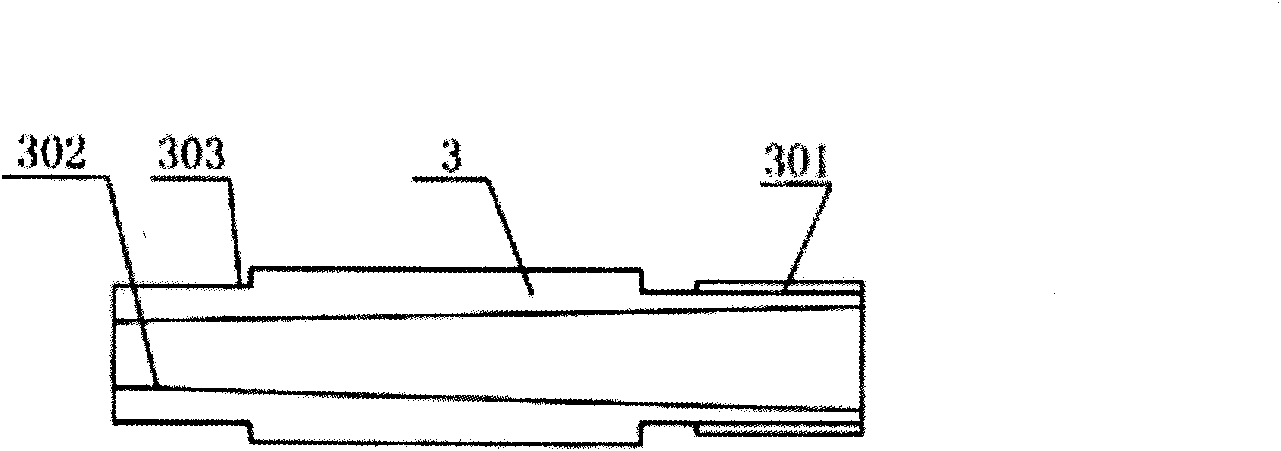

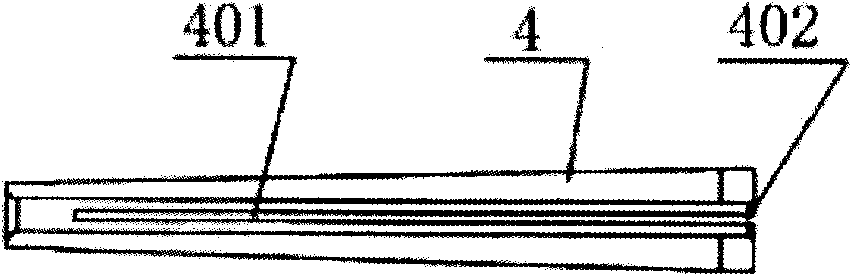

[0026] First, a certain outer cone inner spiral sandwich core 4 is threaded with the first stranded CFCC carbon fiber composite core wire 7 stranded carbon fiber composite core 8 to ensure that at least a little twisted carbon fiber composite core 4 needs to be exposed at the large end of the outer cone inner spiral sandwich core 4. Core 8. The outer cone and inner spiral sandwich core 4 with twisted carbon fiber composite core 8 is inserted into the inner cone and outer thread jacket 3 to ensure that the outer taper of the outer cone and inner spiral sandwich core 4 is consistent with the inner cone and outer thread jacket. 3 The internal taper 302 coincides. Simultaneously, for the second section of stranded CFCC carbon fiber composite core wire 7 stranded carbon fiber composite core 8, implement according to the implementation method of the first section of stranded CFCC carbon fiber composite core wire 7 stranded carbon fiber composite core 8.

[0027] Screw one end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com