Fully-automatic sticking machine of secondary battery electrode slice insulating tape

A technology of insulating tape and secondary battery, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of uneven bonding strength, high labor intensity, easy fatigue of hands and eyes, etc., achieves convenient installation and use, and simplifies the bonding process , The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

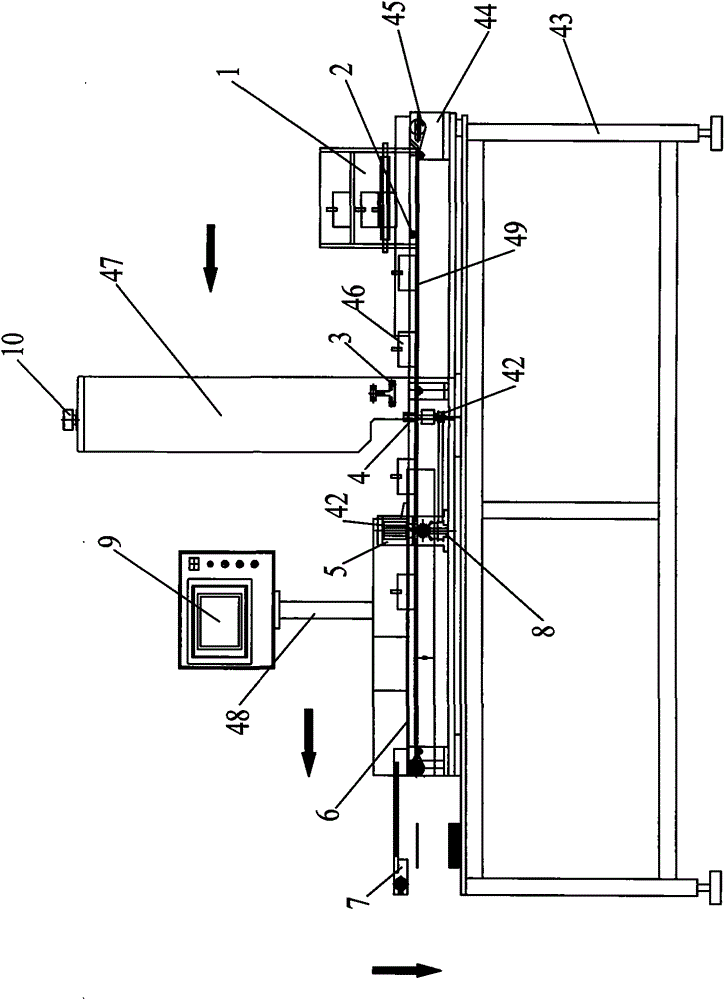

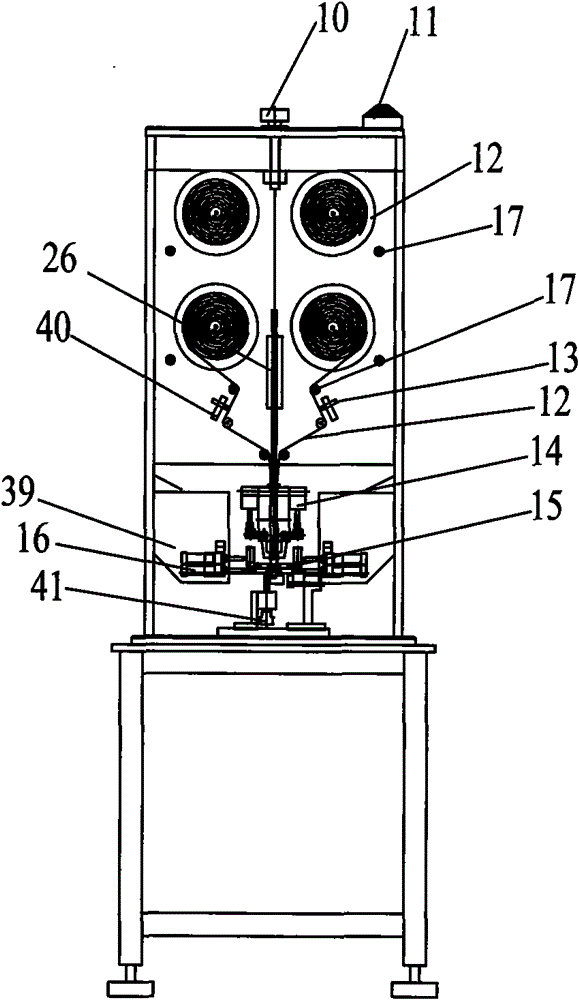

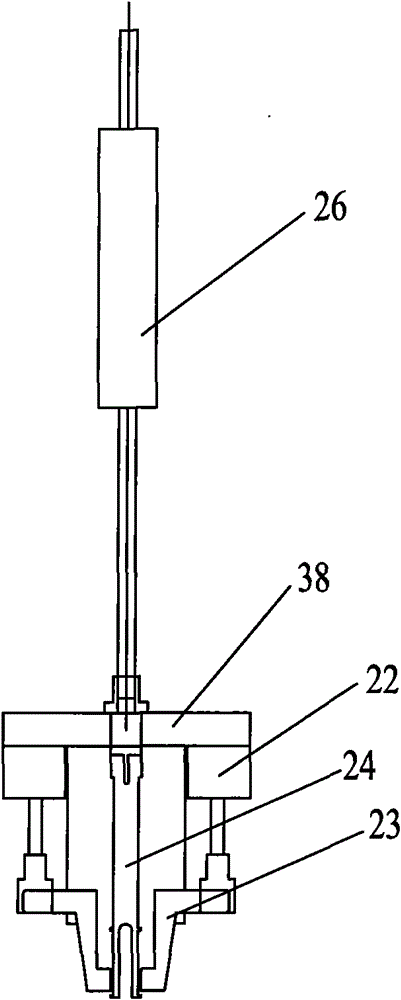

[0019] Such as Figure 1 to Figure 6 As shown: the present invention includes a lower hopper 1, a discharge sensor 2, a tab position sensor 3, a pole piece roller 4, an insulating tape roller 5, a conveyor belt 6, a material receiving mechanism 7, a stepping motor 8, a control Device 9, adjusting screw 10, warning light without insulating tape 11, insulating tape feeding tray 12, insulating tape shortage sensor 13, automatic insulating tape feeding mechanism 14, insulating tape fusing mechanism 15, pole piece clamping mechanism 16, insulation Tape guide wheel 17, insulating tape fusing cylinder 18, electrode fixture 19, heating sheet 20, pole piece clamping block 21, clamping cylinder 22, insulating tape clamping block 23, insulating tape feeder 24, insulating tape straightening air hole 25. Insulation tape feeding cylinder 26, feeding conveyor belt 27, silo 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com