Projection-type capacitive touch screen

A capacitive touch screen, projective technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problem of increased reflected light, poor display effect and visual uniformity of the touch screen, and cannot be completely improved The appearance characteristics of the touch screen and other issues can be eliminated to eliminate the difference in reflected light intensity, the best display effect and visual uniformity, and the effect of eliminating electrode shadow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

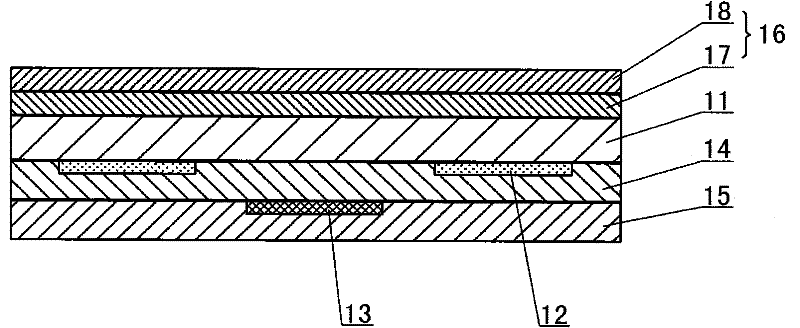

Embodiment 1

[0030] Such as figure 1 As shown, this projected capacitive touch screen includes a transparent substrate 11, on which a touch sensing component is arranged, and the touch sensing component includes a plurality of first sensing electrodes 12 extending along a first direction and a plurality of sensing electrodes 12 extending along a second direction. The second sensing electrodes 13 extending in the same direction, the first sensing electrodes 12 and the second sensing electrodes 13 are interlaced to form a sensing array, the first sensing electrodes 12 are not electrically connected to each other, and the second sensing electrodes 13 are not electrically connected to each other, and the first sensing electrodes 12 and the second sensing electrodes 13 are not electrically connected. The touch sensing part of the projected capacitive touch screen of the present embodiment has a single-sided double-layer structure, that is to say, the first sensing electrode 12 and the second se...

Embodiment 2

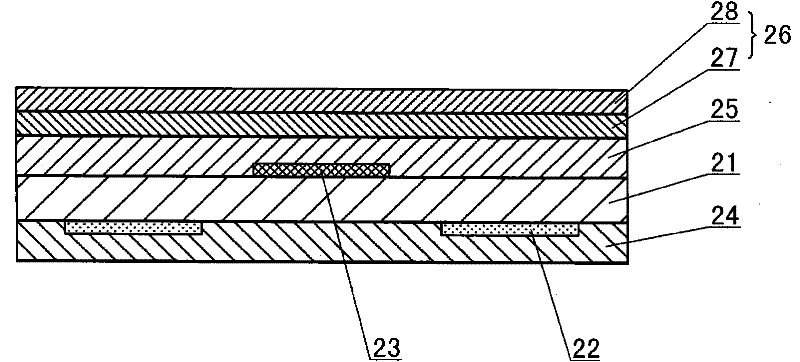

[0034] Such as figure 2 As shown, the touch sensing part of this projected capacitive touch screen is a double-sided structure, and the first sensing electrode 22 and the second sensing electrode 23 of the touch sensing part are respectively arranged on the first conductive film and the second conductive film (touch The sensing component includes a plurality of first sensing electrodes 22 extending along a first direction and a plurality of second sensing electrodes 23 extending along a second direction, the first sensing electrodes 22 and the second sensing electrodes 23 intersect each other A sensing array is formed, each first sensing electrode 22 is electrically disconnected from each other, each second sensing electrode 23 is electrically disconnected from each other, and the first sensing electrode 22 and the second sensing electrode 23 are electrically disconnected. sex is not connected), the first conductive film is on the inner side of the transparent substrate 21, a...

Embodiment 3

[0036] Such as image 3 As shown, the touch sensing part of this projected capacitive touch screen is a single-sided single-layer structure, and the first sensing electrode 32 and the second sensing electrode 33 of the touch sensing part are all arranged on the same conductive surface located on the inner side of the transparent substrate 31. film, and ensure its conduction in their respective directions through a certain bridging structure at the intersection point; the inner side of the entire touch sensing component is covered with an insulating layer 35; the outer surface of the transparent substrate 31 is attached with a polarizer 36 ( Obviously, the polarizer 36 is on the outside of the touch sensing part), the polarizer 36 contains a quarter-wave plate 37 and a polarizing layer 38, the polarizing layer 38 is on the outside of the quarter-wave plate 37, and the absorption axis of the polarizing layer 38 The included angle with the optical axis of the quarter wave plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com