Non-contact on-line detection device of micro gap of wire wrapped screen

A wire-wrapped screen tube and detection device technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of easy fatigue and error of personnel, inconvenient measurement operation, waste of raw materials, etc., to solve the problem of radial vibration and avoid Blurred imaging and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

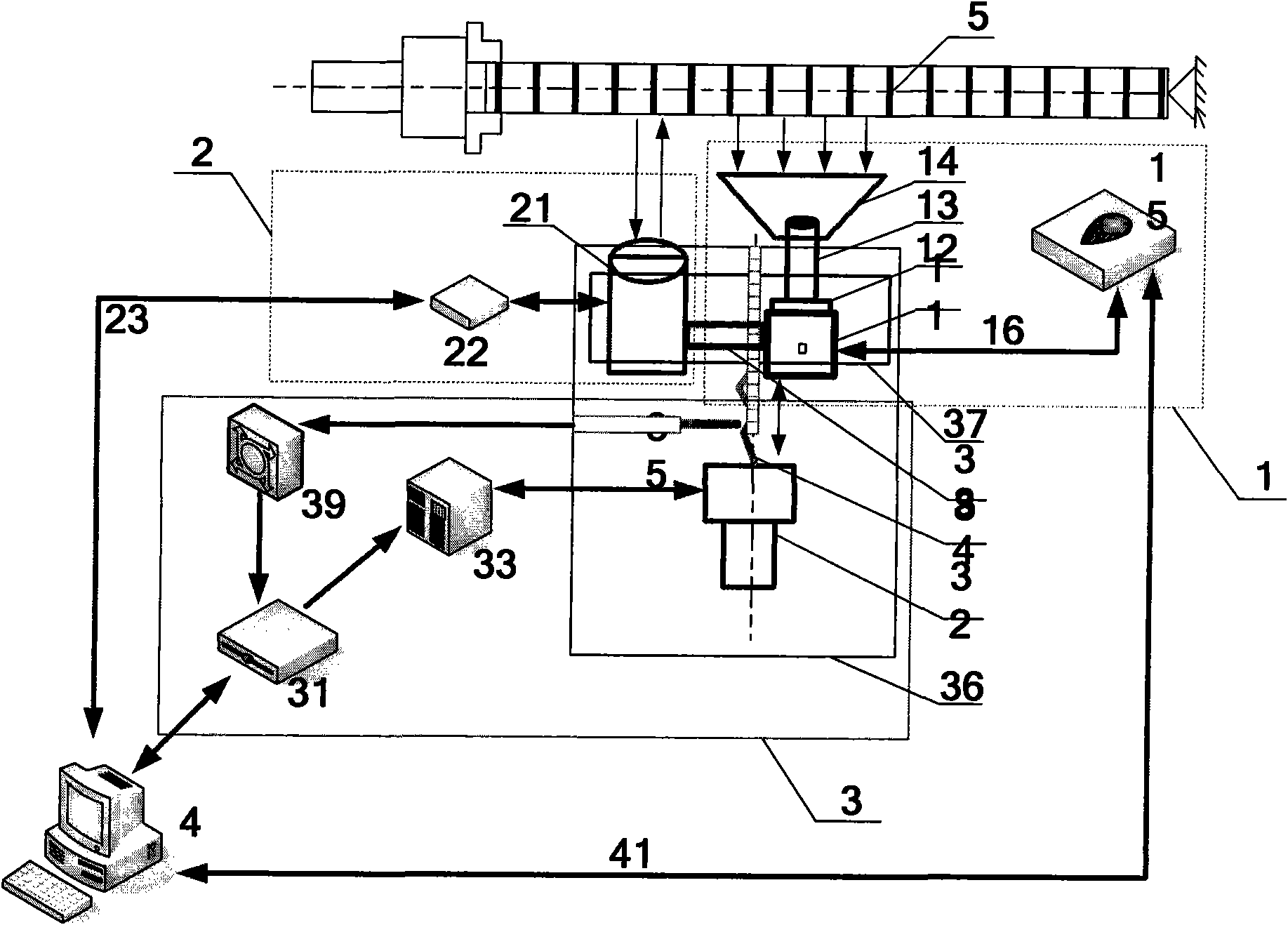

[0038] like figure 1 As shown, the non-contact online detection device for the tiny gap of the wire-wrapped screen tube of the present invention is characterized in that it includes: an image acquisition unit 1, a laser vibration measurement unit 2, an imaging focusing unit 3 and a host computer unit 4, wherein

[0039] The image acquisition unit 1 realizes the real enlarged imaging of the tiny gap of the screen tube 5 under test, and it includes an area array industrial camera 11, an adapter 12, a microscope lens 13, a spherical integrating light source 14 and an image acquisition card 15; wherein the area array industrial camera 11 is connected to the microscope lens 13 through the transfer interface 12; the spherical integral light source 14 is covered at the front end of the microscope lens 13, and uniformly reflects the light emitted from the bottom, so that the illumination on the surface of the screen tube 5 under test is uniform, and the image of the edge of the gap is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com