Flexible steel sheet contact sealing devices and combined sealing structure thereof

A technology of contact sealing and flexible steel sheet, which is applied in engine sealing, indirect carbon dioxide emission reduction, combustion methods, etc., can solve problems such as large air leakage rate, lower power consumption rate of thermal power plants, unreasonable sealing structure, etc., and achieve Low air leakage rate, less maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

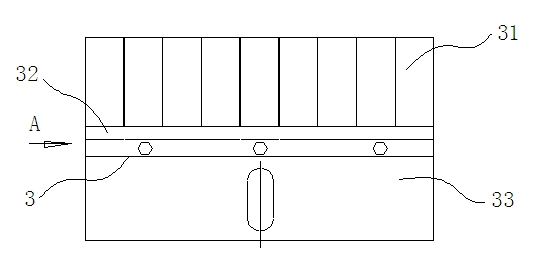

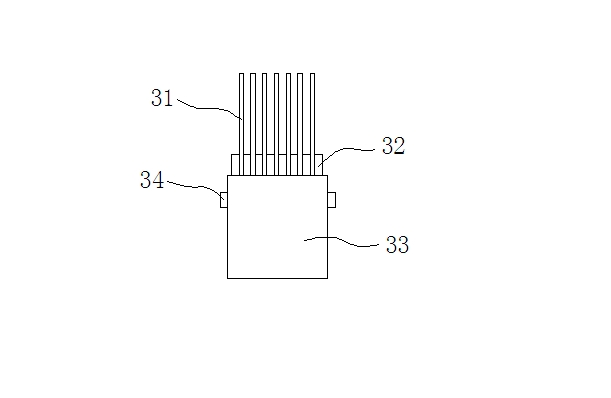

[0034] Embodiment: The flexible steel sheet contact type sealing device of this embodiment, such as figure 1 , 2 As shown, it is composed of a component mounting substrate 33, a flexible steel sheet 31, and a protective sheet 32. The component mounting substrate 33 is block-shaped. A plurality of parallel grooves are formed on the upper end of the component mounting substrate 33, and screws are passed in the grooves. Multiple flexible steel sheets 31 and protective sheets 32 are connected, and the protective sheets 32 are installed between the flexible steel sheets 31. The component mounting substrate 33 is equipped with 7 layers of flexible steel sheets 31, each layer of flexible steel sheet 31 is equipped with a protective sheet 32 on both sides, a total of 8 layers, the protective sheet 32 faces the end of the flexible steel sheet 31 than the end surface of the component mounting substrate 33 It is 8mm higher. Such as image 3 As shown, the flexible steel sheets 31 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com