Preparation method of 1,1,1,3,3-pentafluorobutane

A technology for pentafluorobutane and pentachlorobutane, which is applied in 1 field, can solve problems such as poor mass transfer and heat transfer effects, and achieve the effects of accelerating the reaction speed, increasing the reaction temperature and increasing the reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

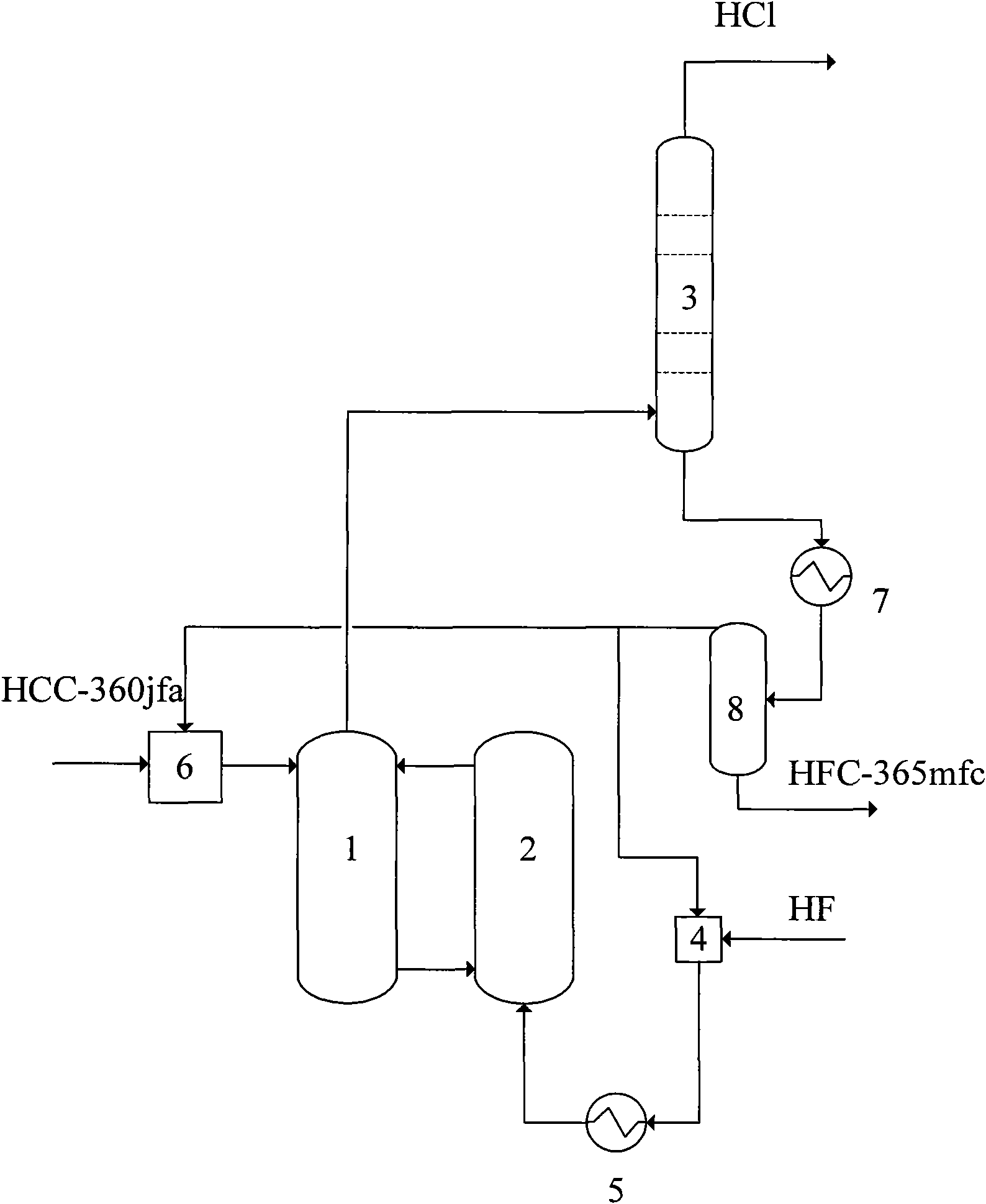

Embodiment 1

[0026] The temperature of the low temperature reaction zone (1) of the liquid phase fluorination reactor is controlled at 90°C, the temperature of the low temperature reaction zone (1) is controlled at 140°C, and the HF entering the liquid phase fluorination reactor is mixed with 1, 1, 1, 3 , the molar ratio of 3-pentachlorobutane is 15:1, the reaction pressure is 1.5MPa, and the catalyst is SbCl 5 . The composition of the organic matter in the lower layer of the phase separator (8) is analyzed by gas chromatography, and the selectivity of HFC-365mfc is 93.3%, and the others are 6.7%.

Embodiment 2

[0028]The temperature of the low temperature reaction zone (1) of the liquid phase fluorination reactor is controlled at 60°C, the temperature of the low temperature reaction zone (1) is controlled at 90°C, and the HF entering the liquid phase fluorination reactor is mixed with 1, 1, 1, 3 , the molar ratio of 3-pentachlorobutane is 15:1, the reaction pressure is 1.0MPa, and the catalyst is SbCl 5 . The composition of the organic matter in the lower layer of the phase separator (8) is analyzed by gas chromatography, and the selectivity of HFC-365mfc is 92.5%, and the others are 7.5%.

Embodiment 3

[0030] The temperature of the low temperature reaction zone (1) of the liquid phase fluorination reactor is controlled at 90°C, the temperature of the low temperature reaction zone (1) is controlled at 110°C, the HF entering the liquid phase fluorination reactor is mixed with 1, 1, 1, 3 , the molar ratio of 3-pentachlorobutane is 6:1, the reaction pressure is 1.2MPa, and the catalyst is SnCl 4 . The composition of the organic matter in the lower layer of the phase separator (8) was analyzed by gas chromatography, and the selectivity of HFC-365mfc was 90.1%, and the others were 9.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com