Control system and method of opening-closing die motor and push-out motor of fully-electric injection molding machine

A technology of motor control and control method, applied in sequence/logic controller program control, comprehensive factory control, electrical program control and other directions, can solve the problems of product overflow product accuracy, control requirements, and uncompact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0178] The present invention will be further described below in conjunction with drawings and embodiments. However, the embodiments of the present invention are not limited thereto.

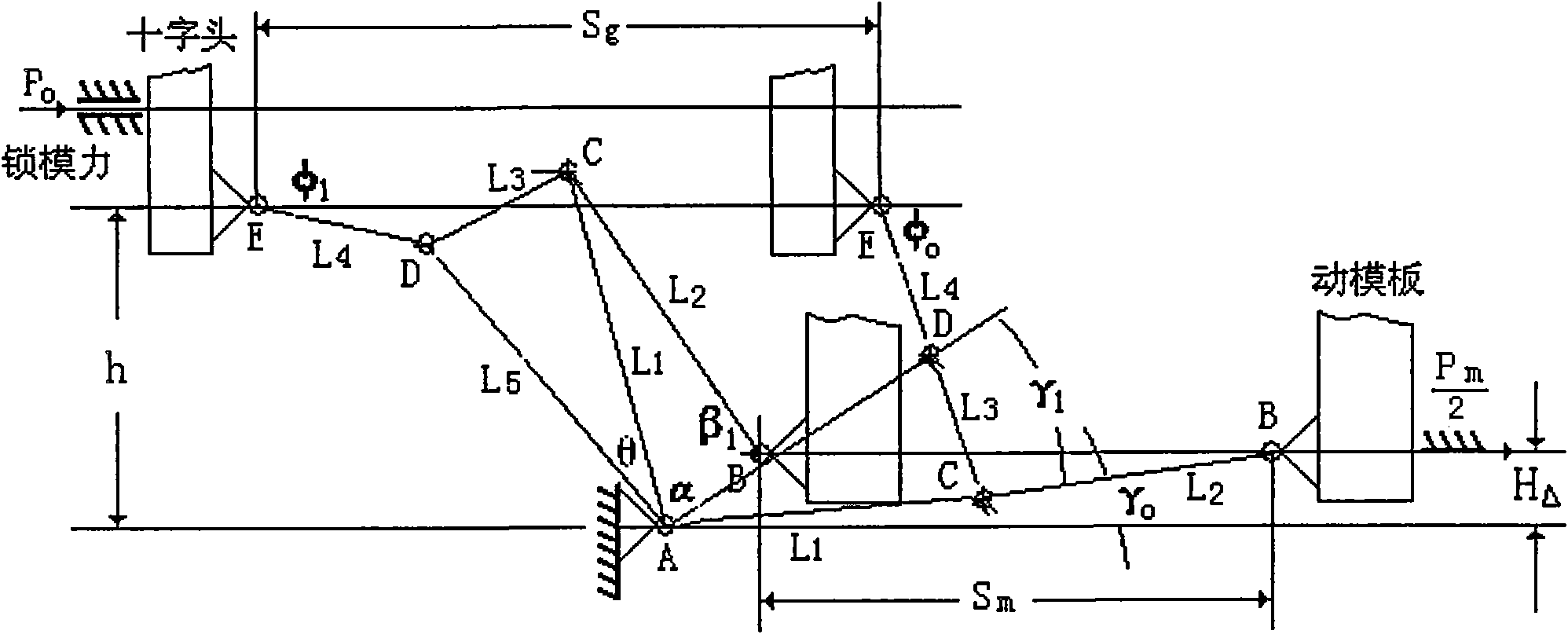

[0179] Such as figure 1 The mold clamping mechanism used by the all-electric injection molding machine is shown, including three parts: five hinge mold double toggle mold clamp mechanism, crank slider ejector device and control system, among which five hinge mold double toggle mold clamp mechanism It consists of mold opening and closing motor, adjusting platen, toggle mechanism, moving platen, moving mold, fixed mold, ejector motor, ball screw, guide rod, and fixed platen. The crank slider ejector device consists of ejector motor, ball wire Rod, ejector rod, top plate, toothed pulley, belt, movable template; one end of the mold opening and closing motor is connected to the adjusting template, the ball screw and the cross head of the toggle mechanism, and the other end of the adjusting template i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com