Processing method and device of metal shell brattice for cambered refrigerator

A metal shell and processing method technology, which is applied to household appliances, hollow objects, other household appliances, etc., can solve the problems of heavy processing machinery, unusable molds, and difficulty in realizing automated operations, and reduce the number of molds and costs. Equipment manufacturing The effect of low cost and easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

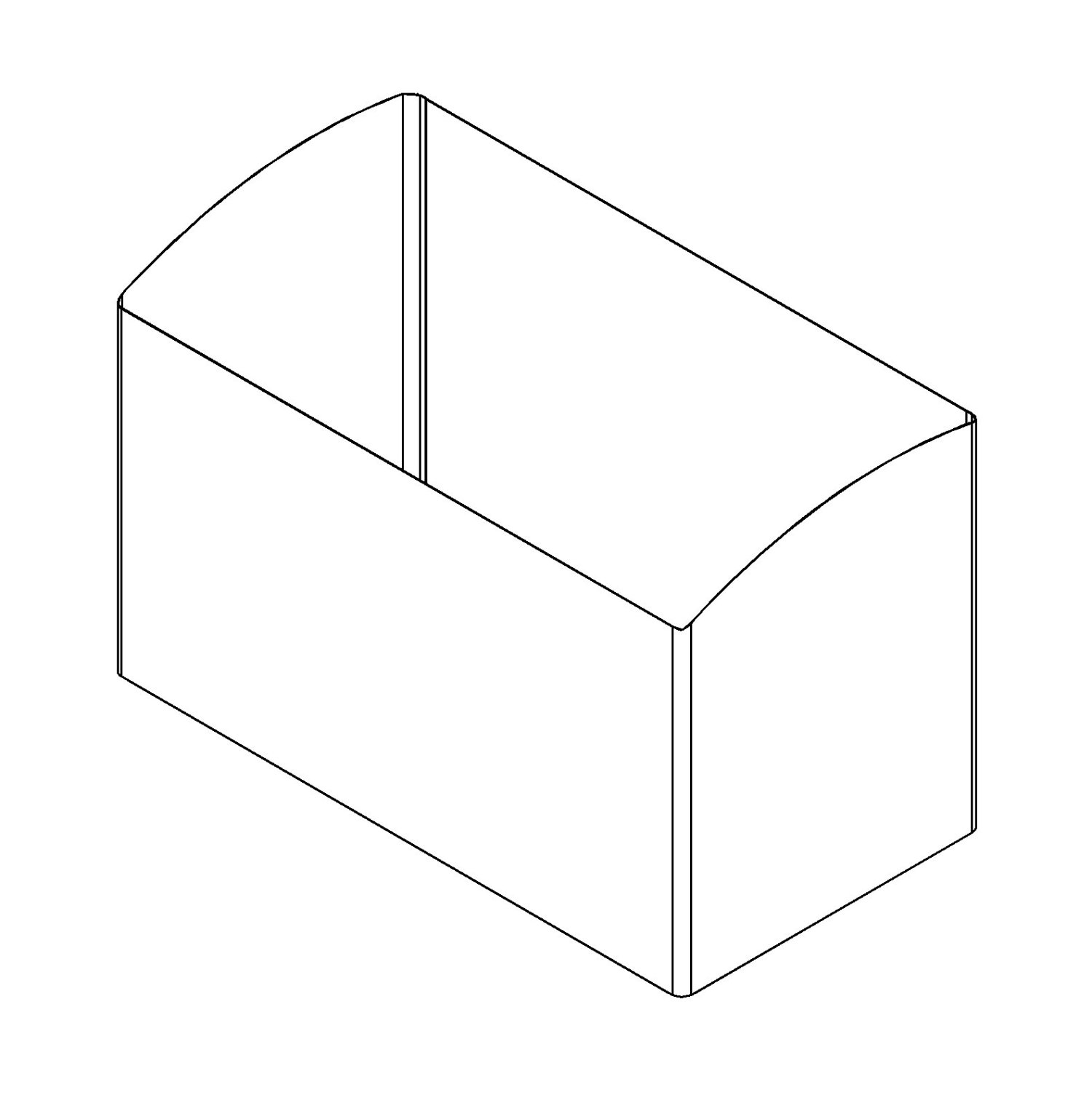

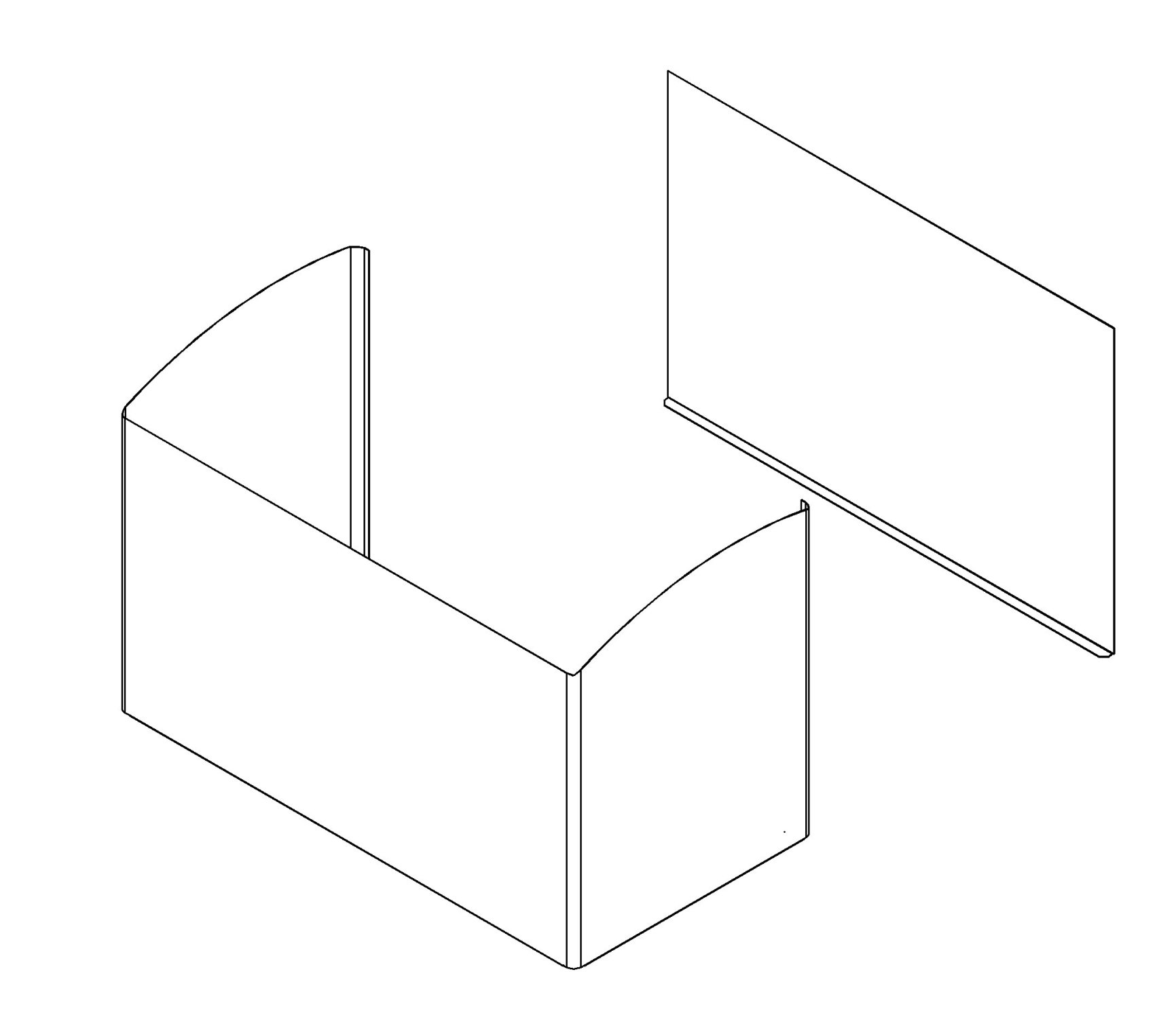

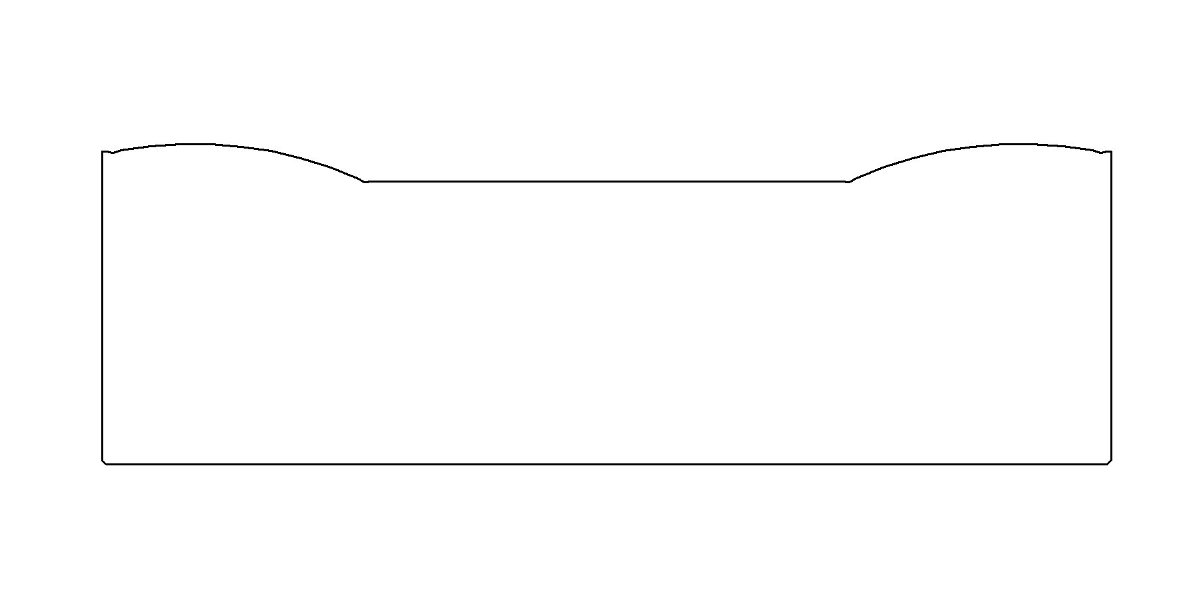

[0015] The processing device for the metal enclosure of the arc-shaped refrigerator, such as Figure 7 , Figure 8 The first station 1 and the second station 2 are set in the front and rear directions of the conveying line for conveying the workpiece 1, and the first station is provided with two pressure punching machines 3 arranged at intervals, and the two punching machines 3 are respectively installed with workpieces. 1 The blanking dies corresponding to the arcs on the left and right sides, the second station is equipped with a linear shearing machine 4, and the front and rear side plates 5 of the linear shearing machine along the conveying direction are provided with opposite shearing plates The notch 6 of the cutting part of the machine is concave inward, and the arc-shaped part 7 of the workpiece 1 can be placed in the notch 6 when cutting the workpiece.

[0016] When the workpiece (rectangular metal plate) placed on the conveyor belt for processing the coaming is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com