Method for controlling consistency of processing quality in heating processes of tobacco shred processing rollers

A technology of spinning drum and processing quality, applied in the field of tobacco processing, can solve the problems of incomplete consistency of material temperature and heating time, affecting the consistency of style and sensory quality, and unable to ensure consistency of material sensory quality and chemical composition changes, etc. Consistent processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

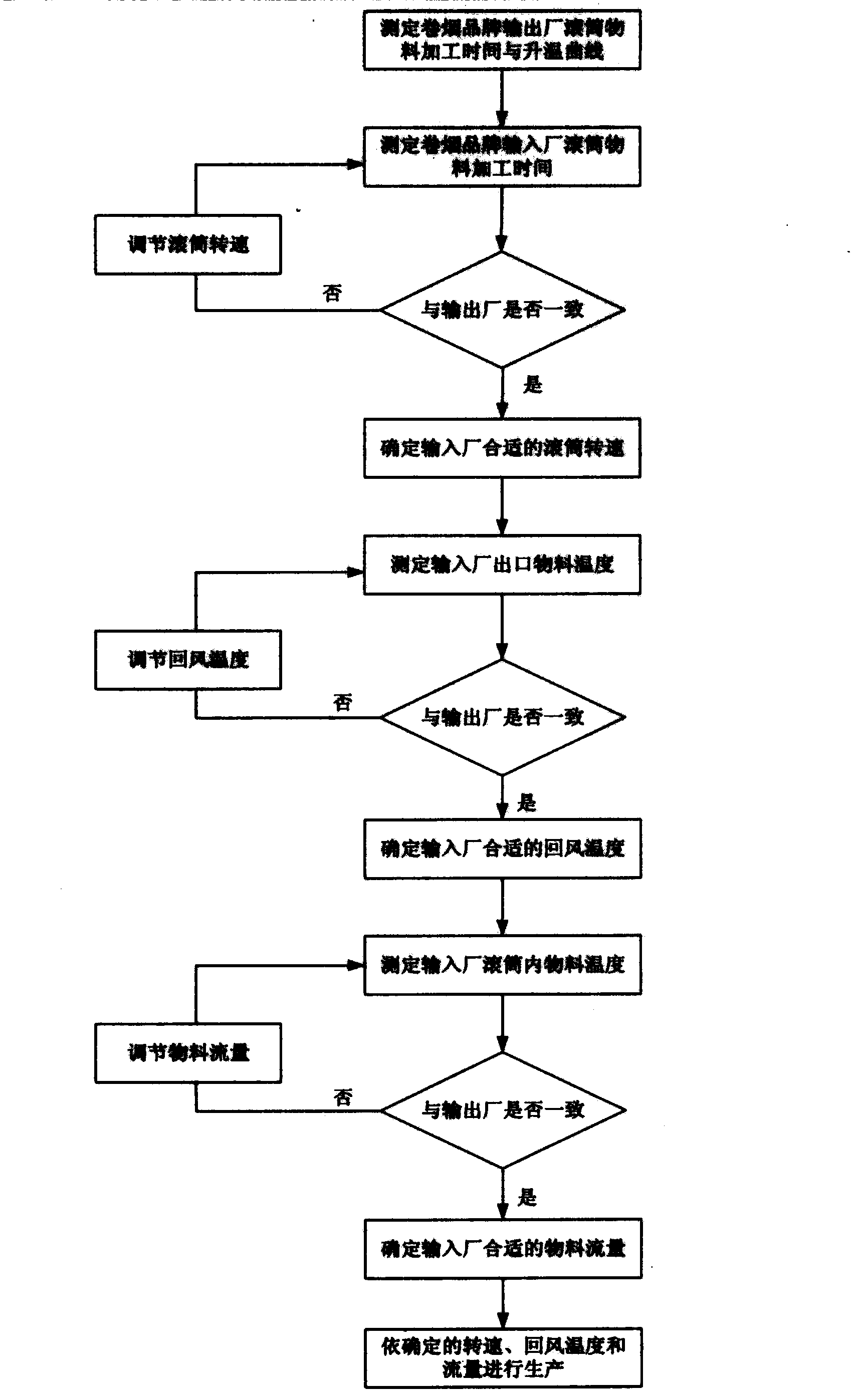

Method used

Image

Examples

Embodiment

[0024] Take factory A (export factory) exporting a certain three types of cigarette brands to factory B (import factory) for processing in the loose rehydration process as an example, the method to maintain the consistency of processing quality in the loose rehydration process is:

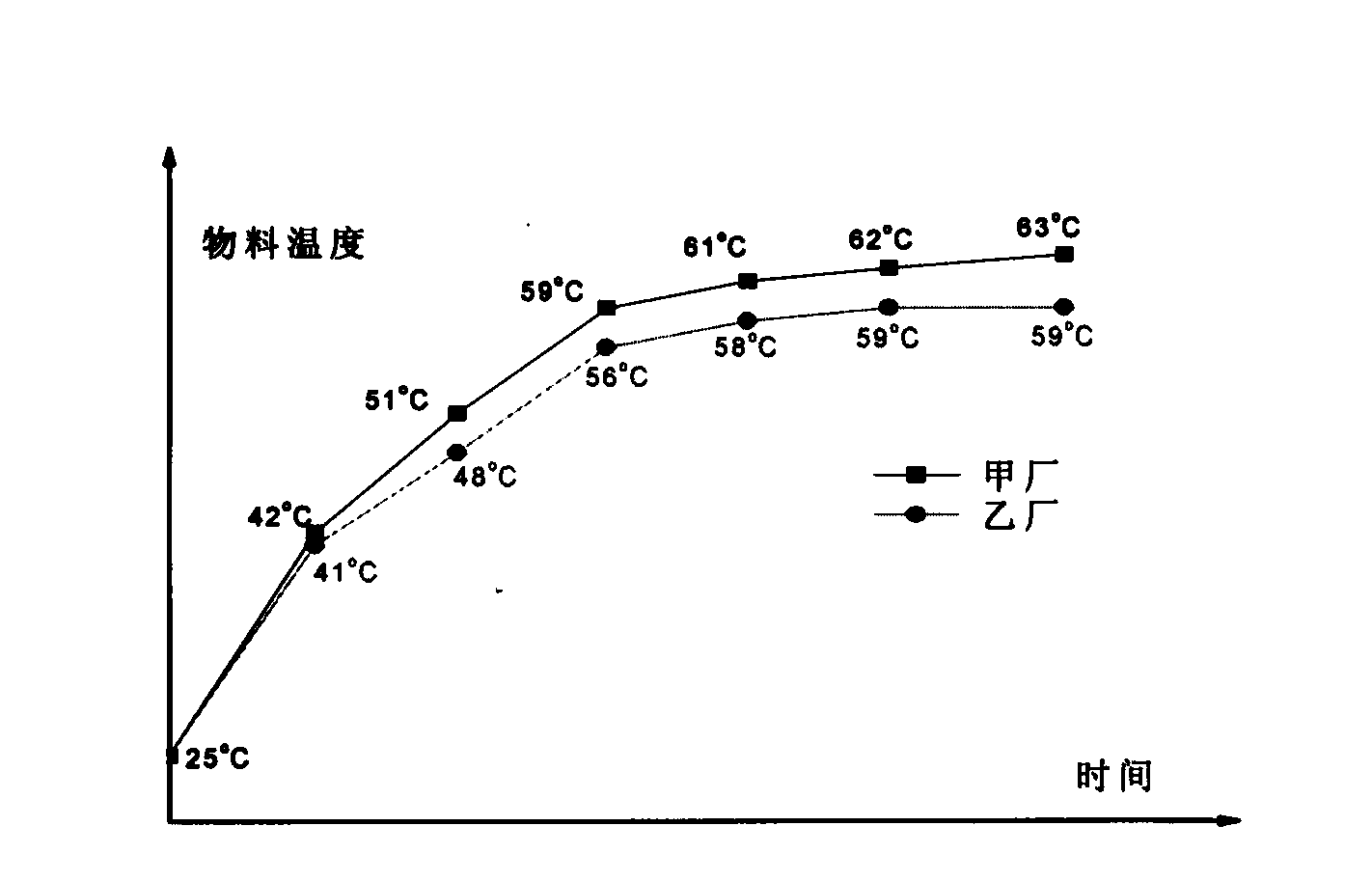

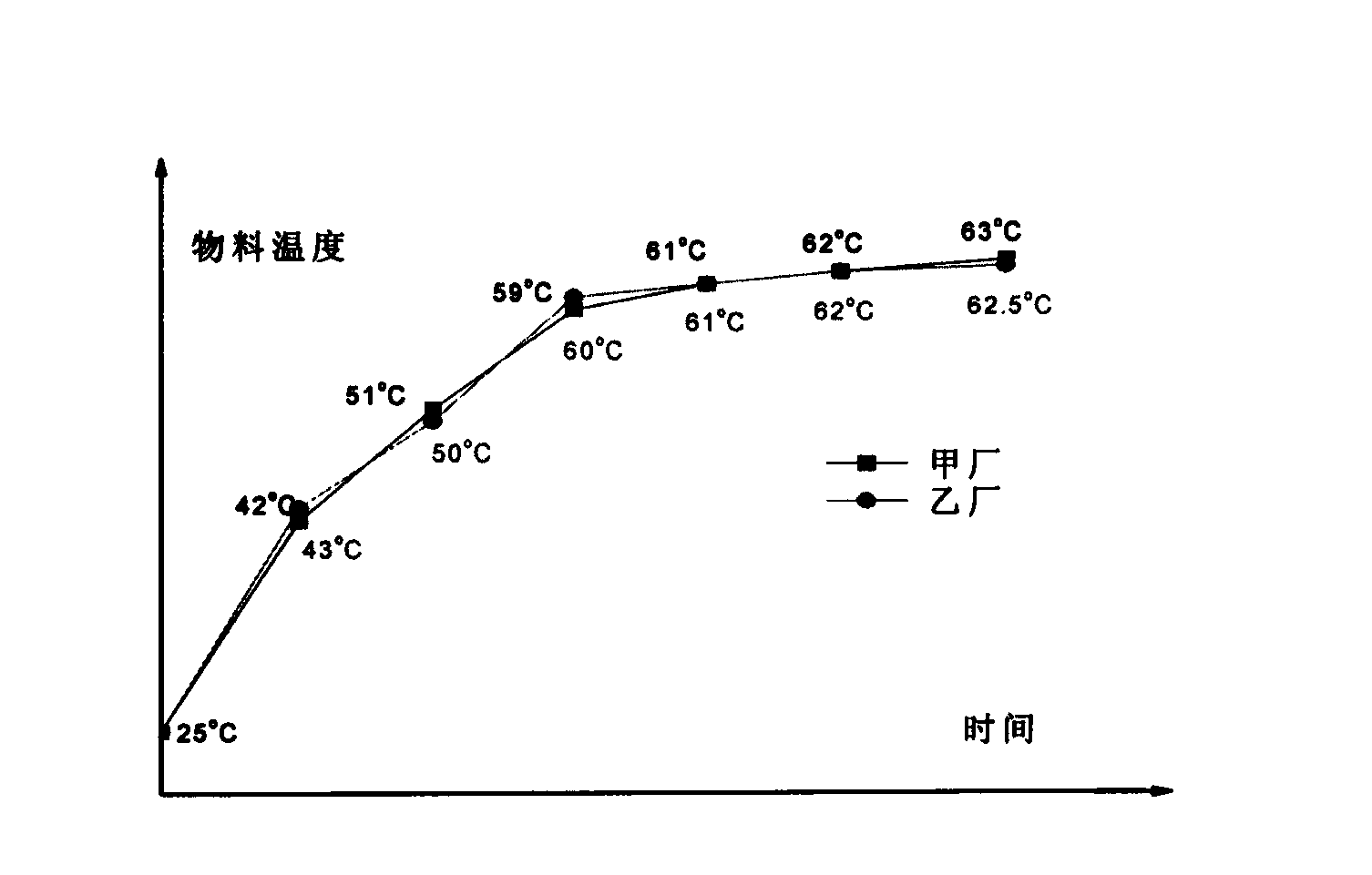

[0025] 1. During the normal production of a certain three-category cigarette brand in Factory A, the material processing time of the loosening and moisture regaining process is determined by weighing method to be 215s, the temperature of the inlet material is 25°C, and the temperature of the outlet material is 63°C. The temperature of the material at the temperature measurement point is 42°C, 51°C, 59°C, 61°C, and 62°C in sequence, and the curve of the temperature of the material in the process of loosening and regaining moisture with the processing time is drawn, as shown in figure 2 (In this embodiment, the temperature measurement points are evenly distributed at equal time intervals, and more te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com