Premix coating trace elements and preparation method thereof

A technology of trace elements and compound trace elements, which is applied in the field of coating trace element premix and its preparation, can solve the problems of trace element loss, accelerated unsaturated fatty acid oxidation, rancidity, and volatile elements, etc., so as to reduce vitamin loss and reduce Fatty rancidity and uniform distribution of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

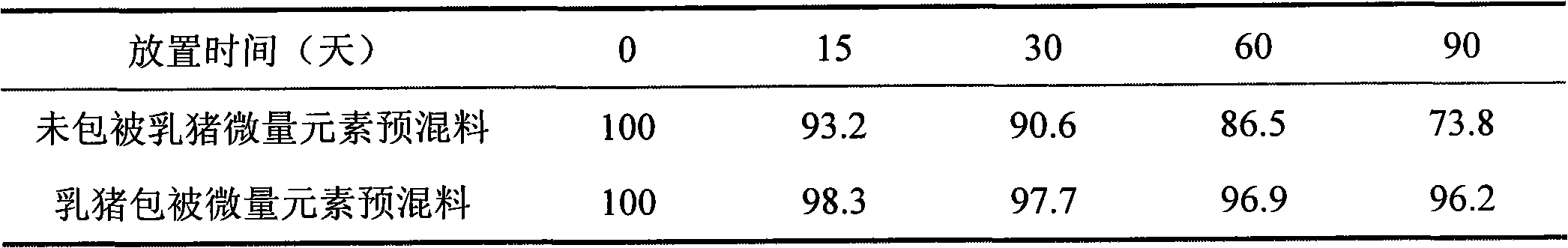

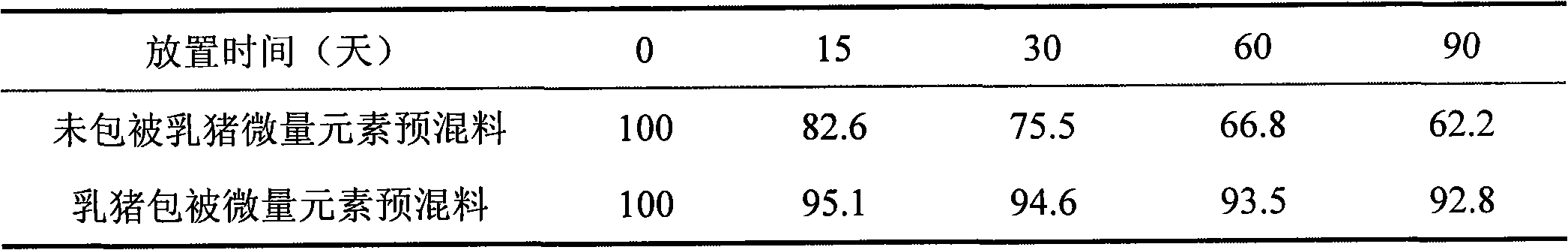

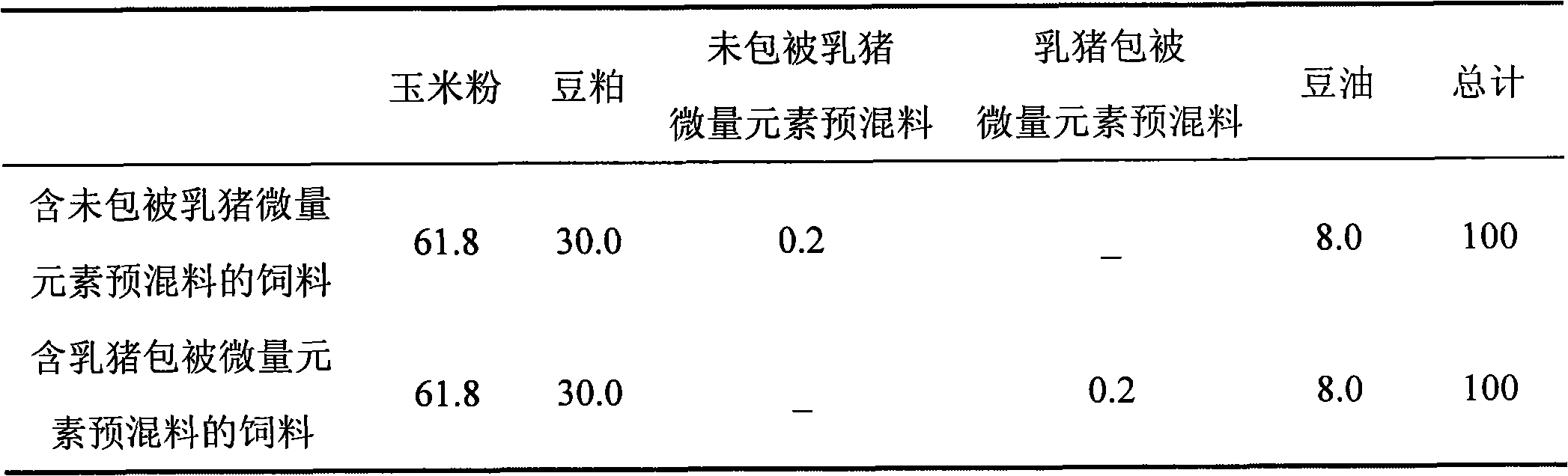

[0050] Suckling pig coated trace element premix

[0051] Prepare suckling pig trace element premix, its compound trace element formula is shown in Table 1, the trace element monomer in Table 1 is pulverized, after passing through a 60-mesh sieve, weigh various trace element monomers, and put them into the mixer Mixed to make complex trace elements.

[0052] Table 1: Trace element premix formula for suckling pigs

[0053] raw material name

Recipe dosage

raw material name

Recipe dosage

ferrous fumarate

101.4kg

Zinc Sulfate Monohydrate

51.9kg

Manganese Sulfate Monohydrate

20.2kg

Copper Sulfate Pentahydrate

16.9kg

1% sodium selenite

8.2kg

5% calcium iodate

1.4kg

[0054] Weigh 120kg of the prepared composite trace elements and put them into the tank mixer, add 50kg of cornstarch, 9kg of talcum powder, 20kg of microcrystalline cellulose, and 1.0kg of gum arabic, add 60kg of tap water while stirrin...

Embodiment 2

[0092] Effects of coated trace element premix on the performance of laying hens

[0093] Table 10: Trace element premix formula for laying hens

[0094] raw material name

Recipe dosage

raw material name

Recipe dosage

Ferrous Sulfate Monohydrate

60.8kg

Zinc Sulfate Monohydrate

72.2kg

Manganese Sulfate Monohydrate

47.3kg

Copper Sulfate Pentahydrate

9.4kg

1% sodium selenite

8.5kg

5% calcium iodate

1.8kg

[0095]According to the formula in Table 10, copper sulfate pentahydrate was first dried at 90°C for 1.5 hours, crushed to 60 mesh, and then all the materials were put into a mixer and mixed to make composite trace elements for laying hens. Get 160kg of the compound trace elements that the above-mentioned prepared laying hens use and put into the trough mixer, add 60kg of tap water while stirring, add 20kg of cornstarch, 3kg of talcum powder, 16kg of microcrystalline cellulose, and 1.0kg of gum a...

Embodiment 3

[0106] Medium and large pig coated trace element premix

[0107] Prepare medium and large pig coated trace element premix, its composite trace element formula is shown in Table 13, the trace element monomer in Table 13 is pulverized, after passing through a 60-mesh sieve, various trace element monomers are weighed, and put into Mix in the mixer to make compound trace elements.

[0108] Table 13: General Trace Element Premix Formula for Zhongda Pig

[0109] raw material name

[0110] Weigh 120kg of the above-mentioned compound trace elements commonly used for medium and large pigs, put them into a trough mixer, add 55kg of cornstarch, 5kg of talcum powder, and 20kg of microcrystalline cellulose, add 50kg of tap water while stirring, and mix to form a soft material Then add it into the swinging granulator, extrude it into a cylindrical chain-shaped material with a 60-mesh sieve, and then put the cylindrical material into a spheronizer for 15 minutes; dry it with hot a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com