Advancing machine

A technology of roadheader and traveling mechanism, which is applied in the direction of slitting machinery, earthwork drilling and mining, etc., which can solve problems such as rock shedding, and achieve the effect of improving cross-section adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

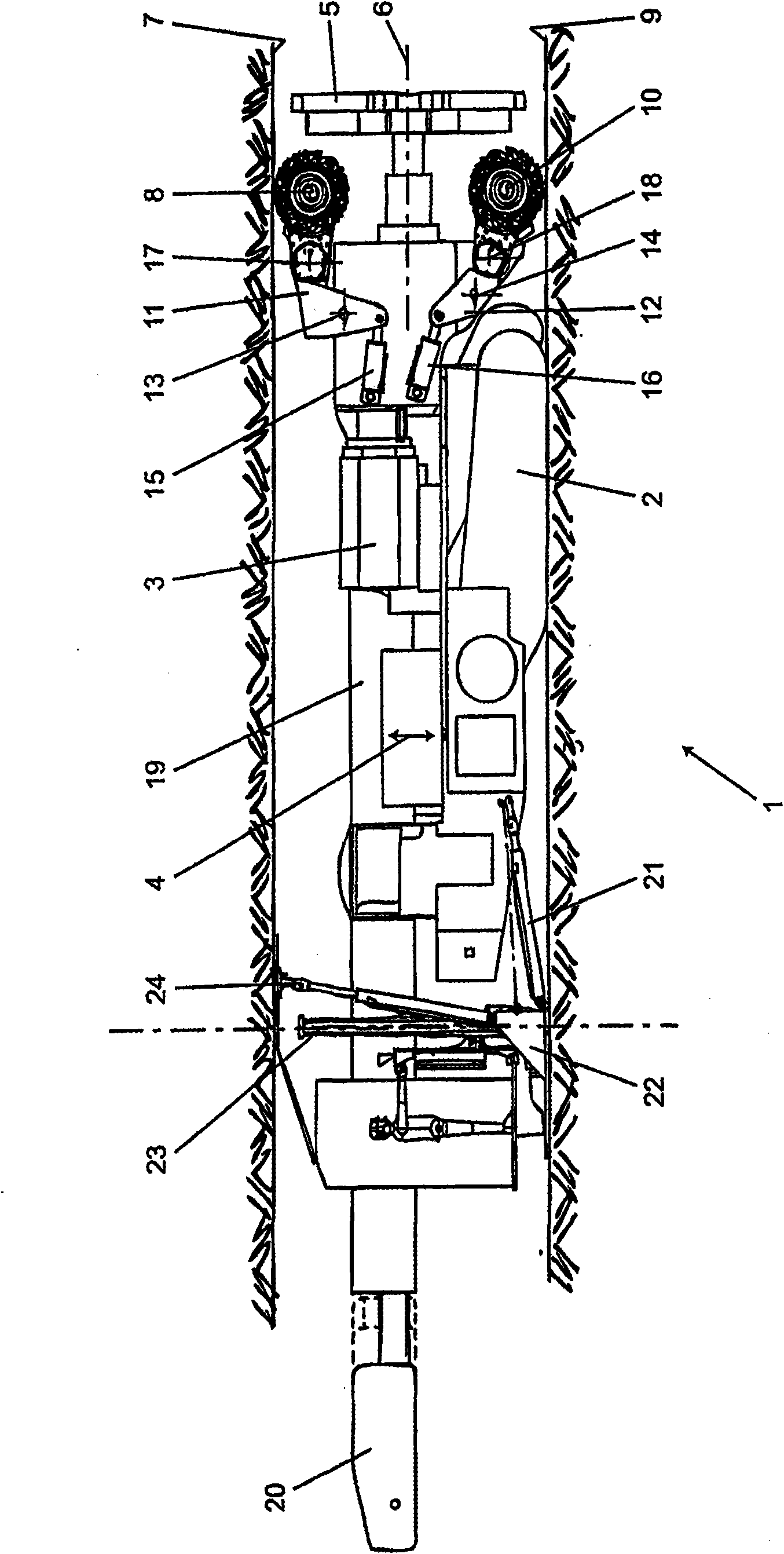

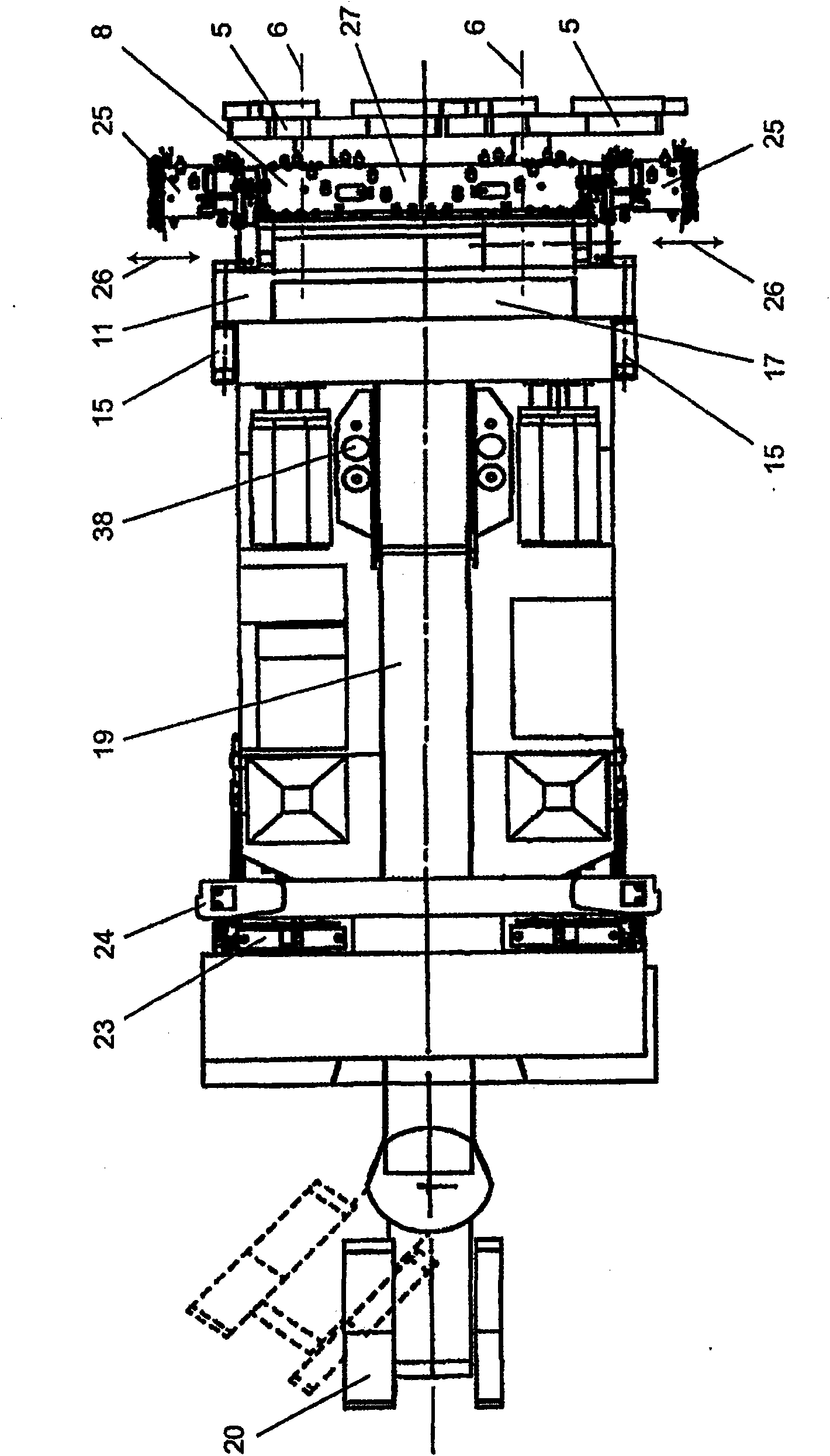

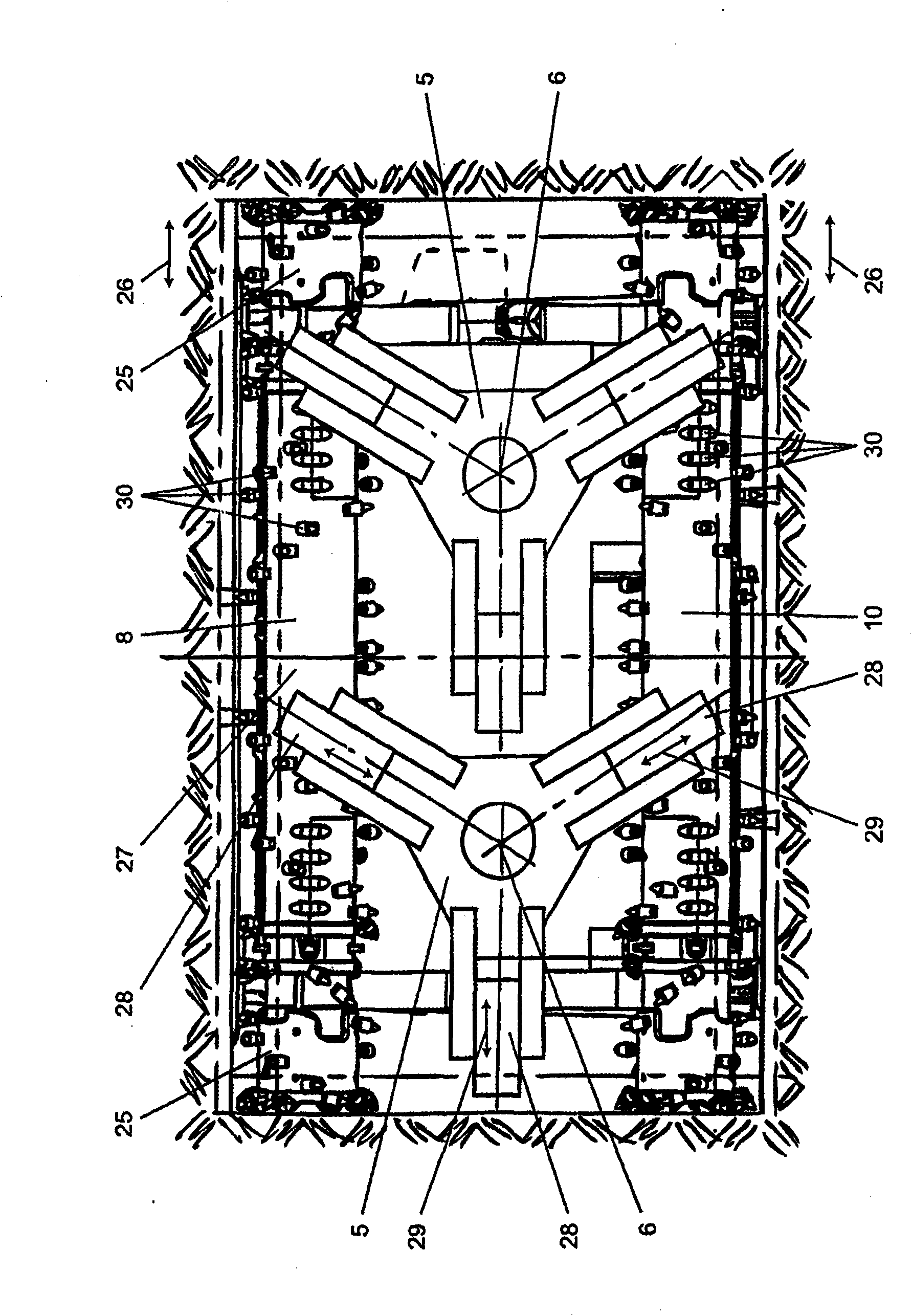

[0017] exist figure 1 In , the roadheader is marked by 1 and has a traveling mechanism 2. The carriage is here configured as a carriage mechanism. A cutting body 5 is mounted on the cutting arm 3 , which can be adjusted vertically along the double arrow 4 by means of a corresponding adjusting device, the cutting body 5 being driven rotatably about an axis of rotation 6 .

[0018] Behind the cutting body 5 there are provided a cutting roller 8 which can be positioned on the top plate 7 and a cutting roller 10 which can be positioned on the bottom plate 9 . Here the cutting rollers 8 and 10 are fixed to a pivot arm 11 or 12 which is pivotable relative to the cutting arm 3 about an axis 13 or 14 . The hydraulic cylinders 15 and 16 each function as a pivot drive. Each of the two cutting rollers 8 and 10 is coupled to a single drive 17 or 18 respectively.

[0019] figure 1 Also depicted is a traction device 19 which extends in the longitudinal direction of the machine as far b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com