Direct current quick breaker

A technology of rapid circuit breaking and circuit breaker body, which is applied to circuit breaker components, circuits, electrical components, etc., can solve the problems of elongated arc, increased arc burning time, and large arc resistance, and achieves improved arc resistance and arc voltage. The effect of reducing the arcing time and improving the arc extinguishing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

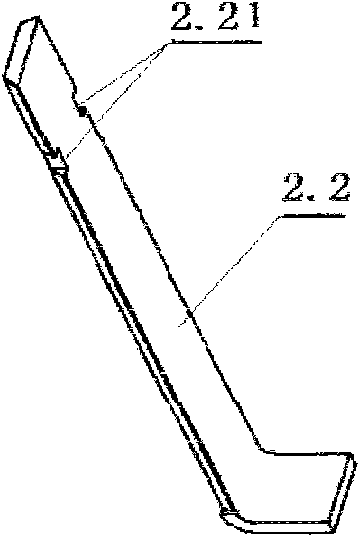

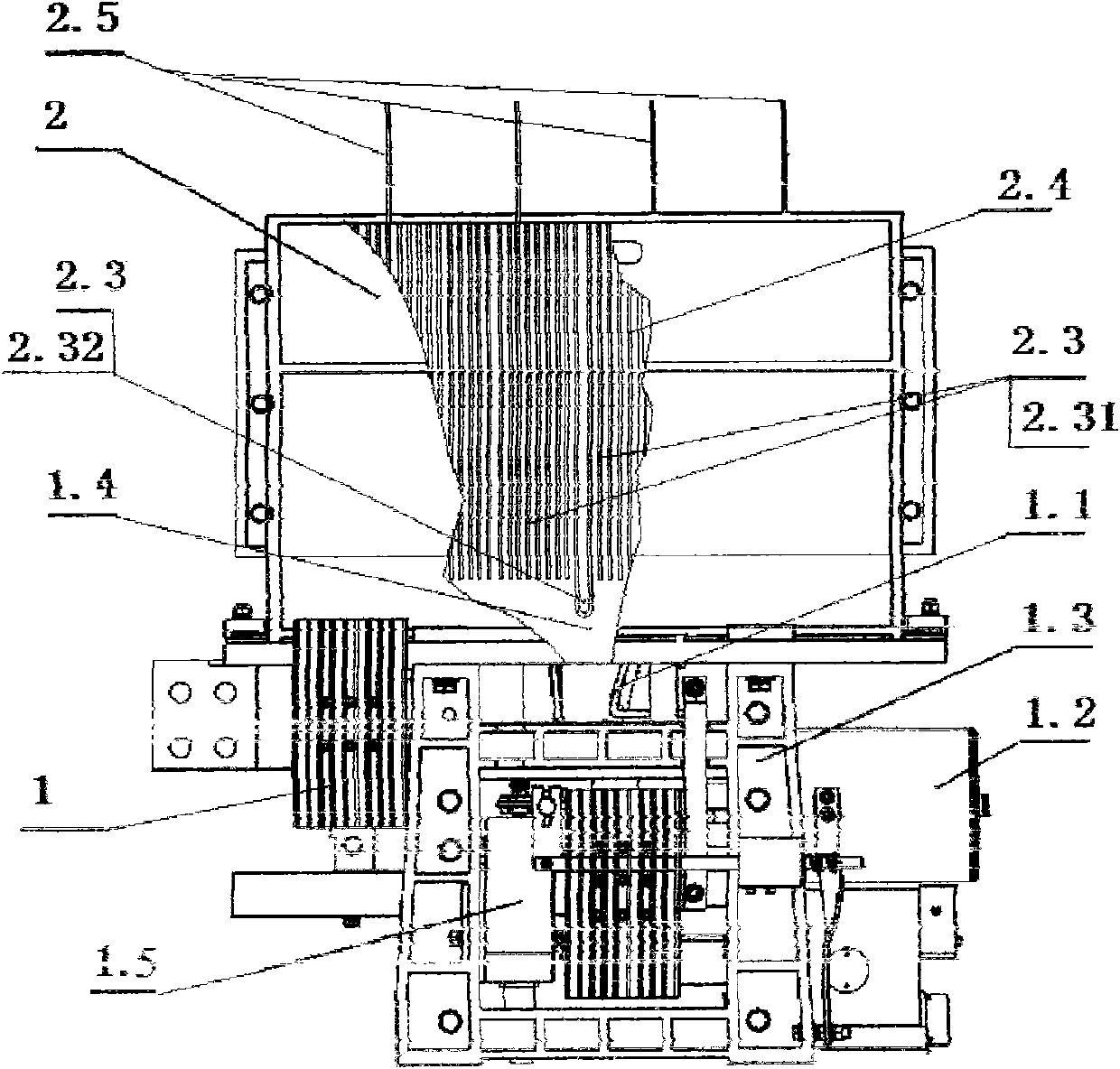

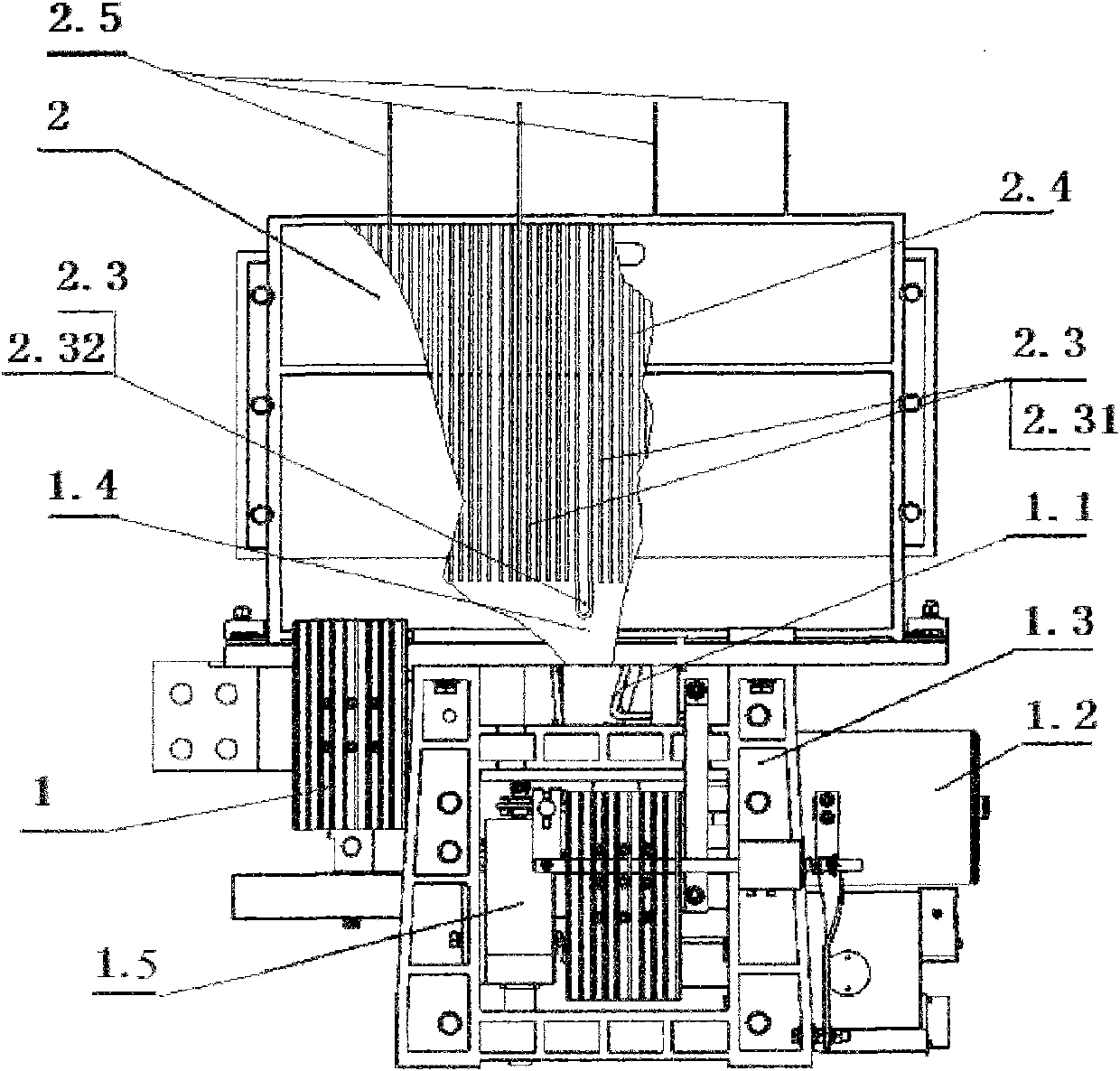

[0035] like figure 1 , 2 As shown in , 8: it is a DC fast circuit breaker, which has a circuit breaker body 1 and an arc extinguishing chamber 2; the circuit breaker body 1 has a contact system 11, an operating mechanism 1.2, a frame 1.3, and a release device 1.5; The arc extinguishing chamber 2 has a pair of insulating shells 2.1, an arc strike angle 2.2, and the inner cavity of the arc extinguishing chamber 2 has a metal grid 2.3, an insulating grid 2.4, and a diaphragm 2.5; wherein the metal grid 2.3 and the insulating grid 2.4 Located in the middle of the arc extinguishing chamber 2, the transverse partition 2.5 is located on the upper part of the arc extinguishing chamber 2; this embodiment is for example figure 2 As shown: there are a pair of insulating shells 2.1, a pair of arc strike angles 2.2, a group of metal grids 2.3, insulating grids 2.4, and four transverse partitions 2.5 to form an arc extinguishing chamber 2; the metal grids 2.3 are flat The part is the fro...

Embodiment 2

[0037] Different from the above-mentioned embodiment 1, the arc extinguishing chamber 2 of this embodiment is as Figure 9 As shown: there are a pair of insulating shells 2.1, a pair of arc striking angles 2.2, a group of metal grids 2.3, insulating grids 2.4, and two transverse partitions 2.5 to form the arc extinguishing chamber 2; the structure of this embodiment reduces the straight plate type The number of metal grids 2.31, insulating grids 2.4, and transverse partitions 2.5, and the length of the insulating housing 2.1 are correspondingly reduced. This embodiment can be applied to circuit breakers with lower voltage levels. The angle of the notch 2.01 of the straight metal grid sheet 2.31 is 90 degrees. The notch 2.02 angle of the U-shaped metal grid 232 is 105 degrees, and the distance between the metal grids 23 is 8 mm.

Embodiment 3

[0039] Different from the above-mentioned embodiment 2, the angle of the notch 2.01 of the straight metal grid 2.31 in this embodiment is 40 degrees; the angle of the notch 2.02 of the U-shaped metal grid 2.32 is 75 degrees, and the The metal grid pieces 2.3 maintain a spacing distance of 2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com