Fence structure

A wall and wall panel technology, applied in the field of new-type walls, can solve the problems of long construction period, high material transportation cost, time-consuming, labor-intensive and labor-intensive problems, and achieve the effect of convenient construction, reduction of engineering cost, and reduction of wet work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

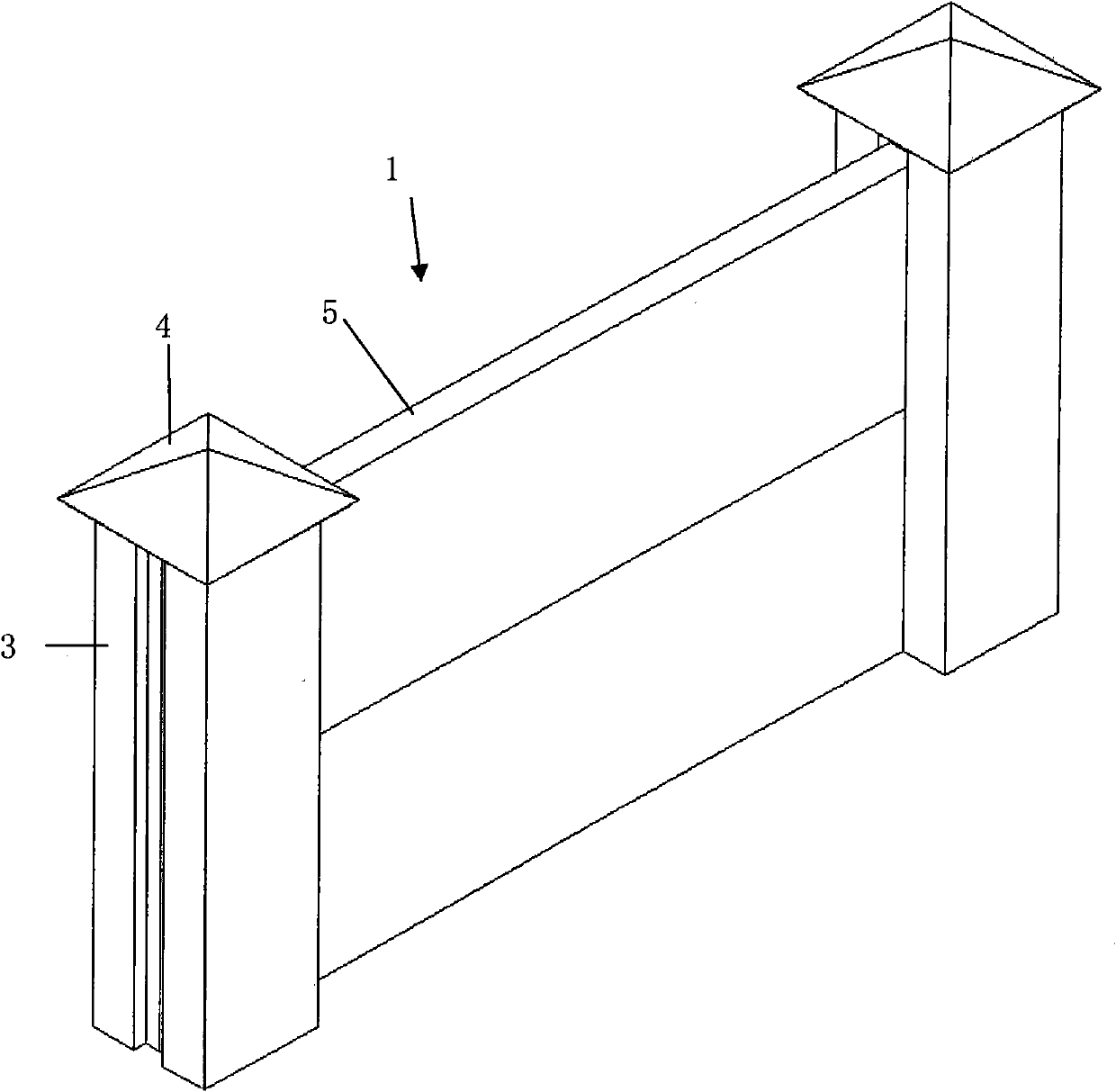

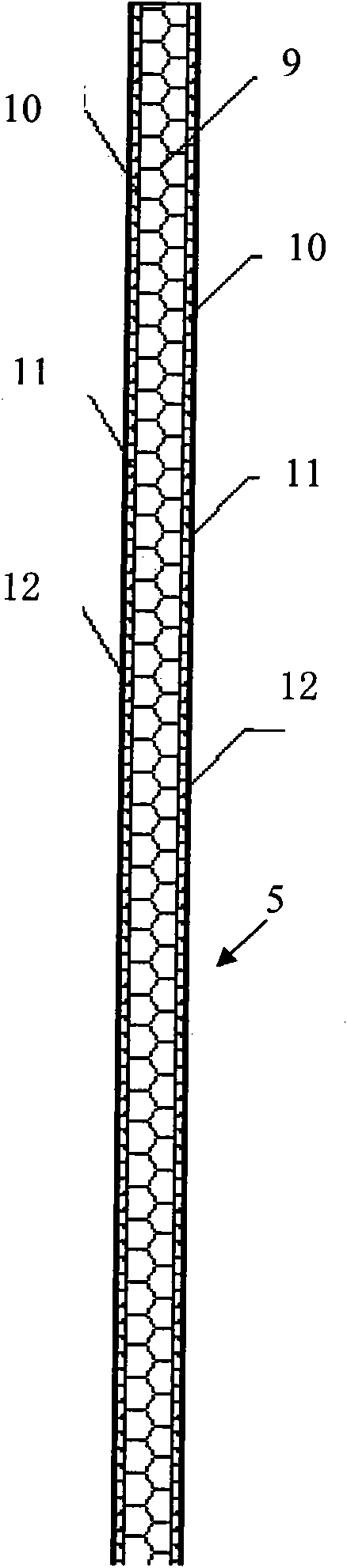

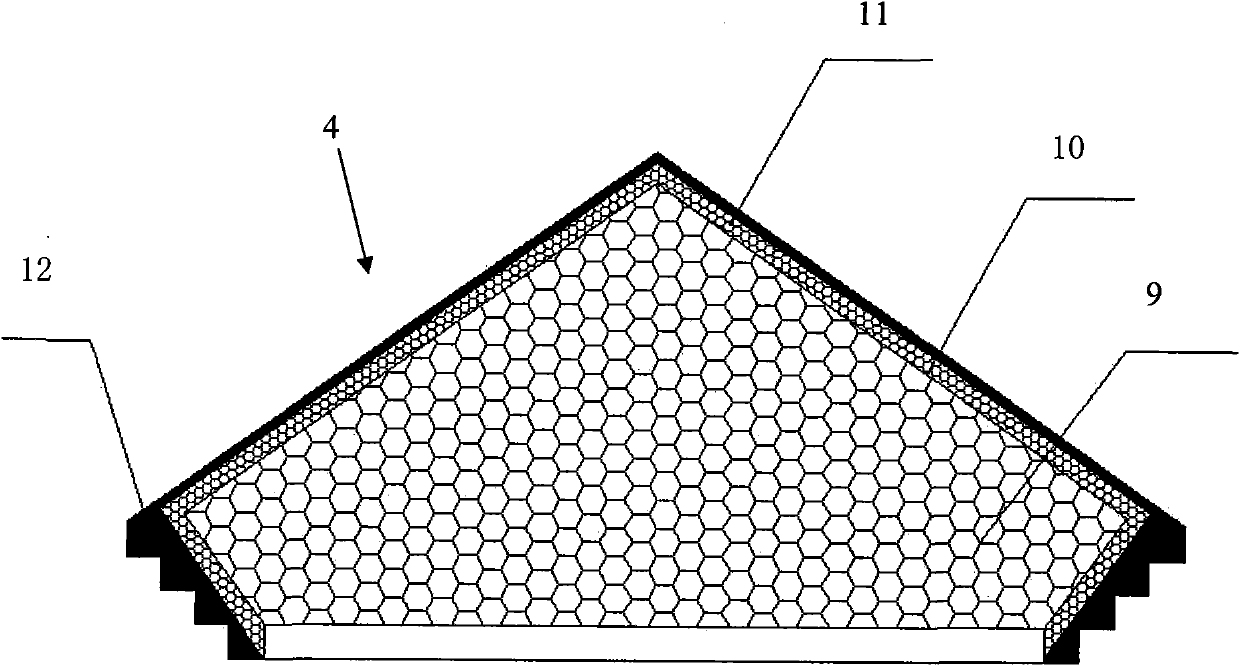

[0029] Embodiment 1: prepare wall 1, such as Figure 1 to Figure 5 Shown, enclosure wall 1 is made of central column 2, column body 3, column cap 4, wallboard 5. Square or circular column center column 2, on the center column 2, use construction glue or connectors to connect two columns 3, the column body 3 is made of polystyrene board 9, reinforced mesh 10, plastering layer 12 or polystyrene board 9. Reinforcing mesh 10. A long cube made of adhesive layer 11 made of adhesive mortar and plastering layer 12 made of plastering mortar. The height of column 3 is slightly higher than that of wallboard 5; column 3 One side is plane, the other side is provided with square protrusions 6 and 7, and a square or semicircular depression 8 is set in the middle of the protrusions 6 and 7, and the width of the depression 8 closely matches the width of the central column 2 One side of wallboard 5 is inserted in the groove formed after the merger of two cylinders 3, and the other side of wall...

Embodiment 2

[0041] Embodiment 2 prepares enclosure wall 13, as Figure 6 Shown, wall 13 is made of central column 2, column body 3, column cap 4, wallboard 14, fence 15. The components of embodiment 2: the structure of the central column 2, the column body 3, and the column cap 4 are the same as those of the components of embodiment 1, and the symbols are also the same, so no detailed description will be given.

[0042] Enclosing wall 13 is made of square or circular column center column 2, and two columns 3 are connected on center column 2 with construction glue or connectors, and column body 3 is made of polystyrene board 9, reinforcing net 10, plastering layer 12 or A long cube made of polystyrene board 9, reinforcing net 10, bonding layer 11 made by bonding mortar, plastering layer 12, the height of column 3 is 2 times of enclosure wall 14. One side of the cylinder 3 is a plane, the other side is provided with a square protrusion 6, a protrusion 7, and a square or semicircular depres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com