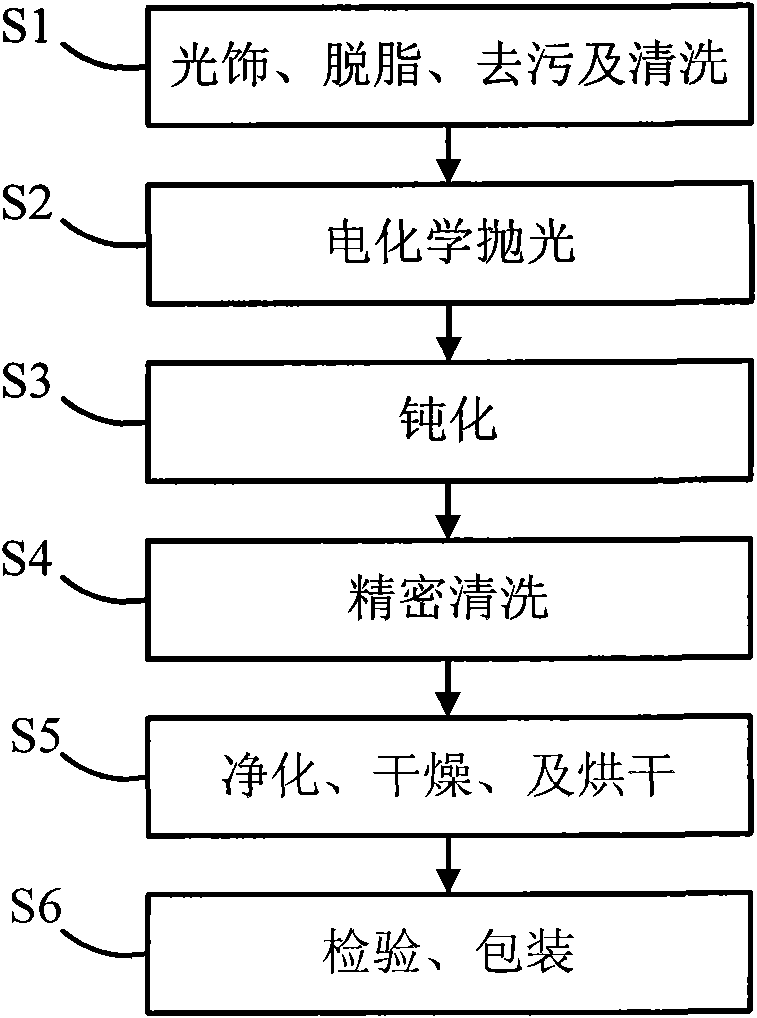

Method for treating stainless steel surfaces

A surface treatment, stainless steel technology, applied in the direction of metal material coating process, can solve the problems such as unreachable, and achieve the effect of simple operation, detailed and clear process, high purity and quality reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The present invention will be further described below through specific examples.

[0053] Choose 316L (V / V) or 316L stainless steel material for parts processing, adjust and control the cutting parameters, so that the cutting stress and roughness generated on the surface of the parts are as small as possible, and the finished parts are measured in a non-contact or small contact force way. Qualified; then carry out light decoration, you can choose honing, abrasive grain flow or cotton, wool and abrasive materials to carry out surface decoration, or you can choose chemical method light decoration; then carry out degreasing and decontamination (select special cleaning agent for composite stainless steel) Ultrasonic degreasing, decontamination, do not use strong alkali solution), spraying, rinsing, cleaning must be thorough, ultrasonic cleaning can be used; then electrochemical polishing (EP), electrochemical polishing (EP) is very important, is the stainless steel surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com