Storage and transportation equipment for outdoor type removable impulse voltage generator

An impulse voltage and generator technology, applied in the container, container, rigid container and other directions of the machine, can solve the problems of high manpower requirements, unsuitable for high requirements, causing accidents, etc., achieve true and accurate test data, and shorten installation and deployment. time, the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

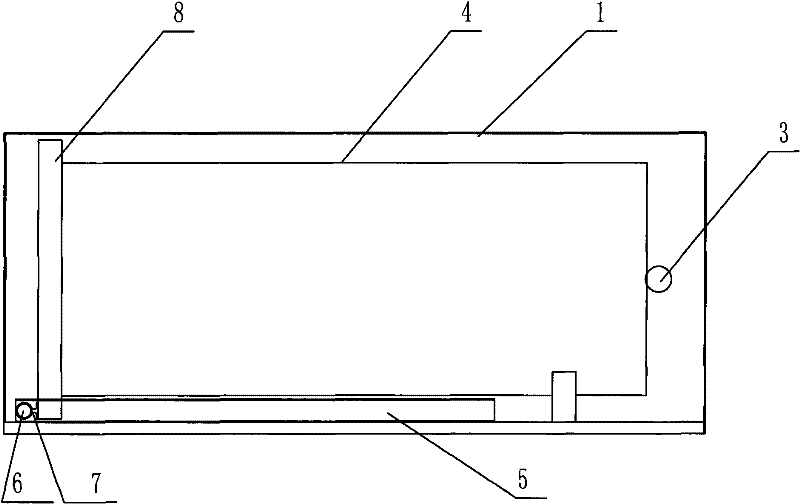

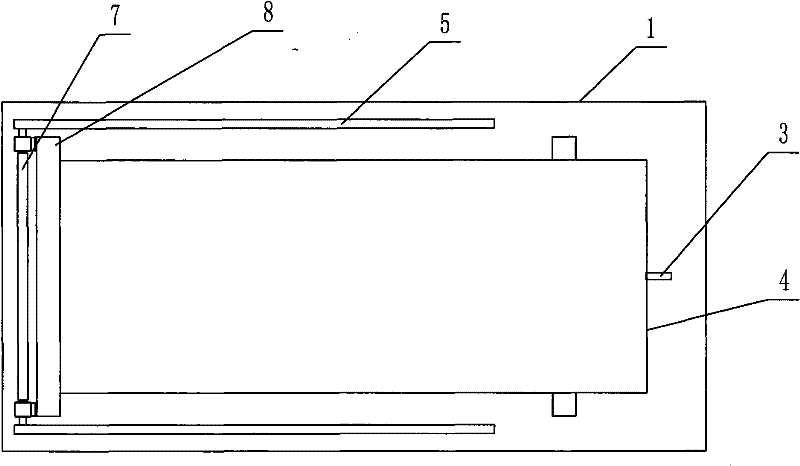

[0027] Such as figure 1 , 2 , 3, and 4, the storage and transportation equipment of an outdoor movable impulse voltage generator according to the present invention includes a container 1 and a container 2, wherein the carrying container 1 is provided with an epoxy barrel with a lifting ring 3 4. The bottom plate of the container 1 is provided with a sliding guide rail 5 with grooves and a rotating shaft 7 with rollers 6 arranged in the grooves of the sliding guide rail 5 at both ends. , the epoxy barrel 4 is sheathed on the outside, and the epoxy barrel 4 is fixedly arranged on the base 8 of the impulse voltage generator body; Turn axis 7.

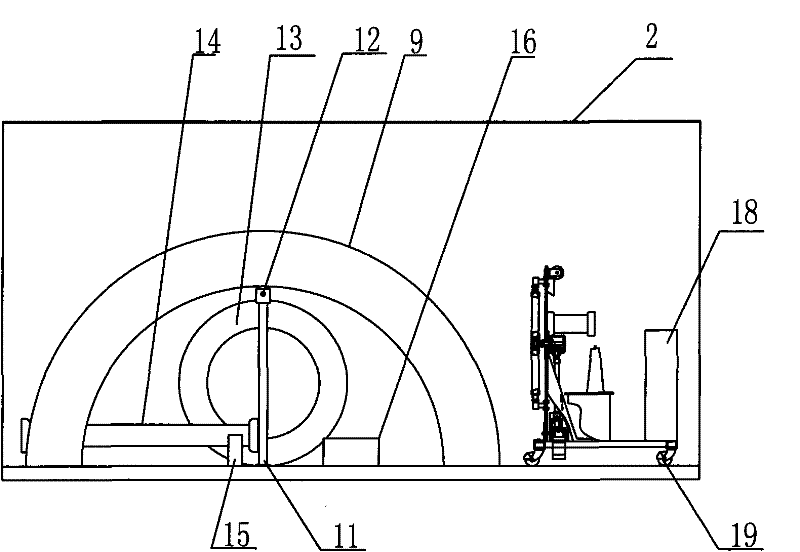

[0028] Such as image 3 , 4 As shown, the container 2 carries other equipment of the impulse voltage generator and is provided with fixing devices for the equipment. Specifically, the pressure equalizing ring 9 of the impulse voltage generator body is divided into two semicircular rings, which are fixedly connected to the flange of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com