Process method for forming integral top cover and heading die thereof

A forming process and upsetting technology, which is applied to the forming process method of the integral top cover and its upsetting mold field, can solve problems such as instability, unsafe use, and difficult one-time forming, and achieve high strength, reliable use, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: a kind of molding process method of integral top cover, its steps are as follows:

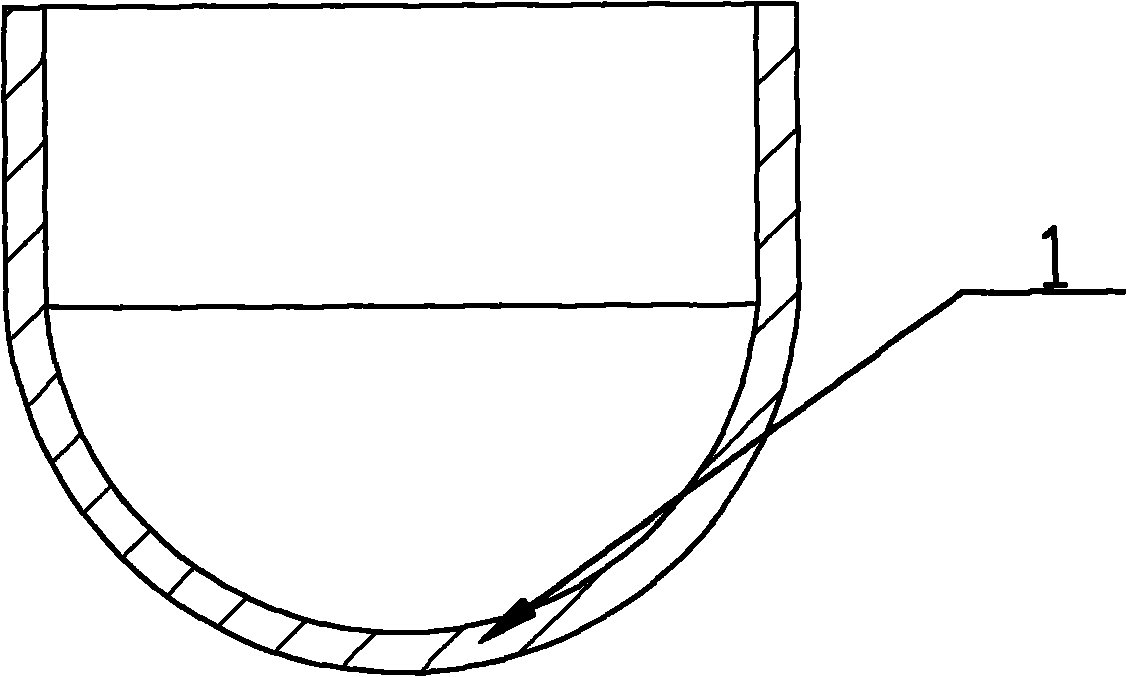

[0022] a. Billet making: after the riser is removed from the high-temperature steel ingot, a distributed extrusion process is used to form a barrel blank 1 with an open upper end and a closed lower end;

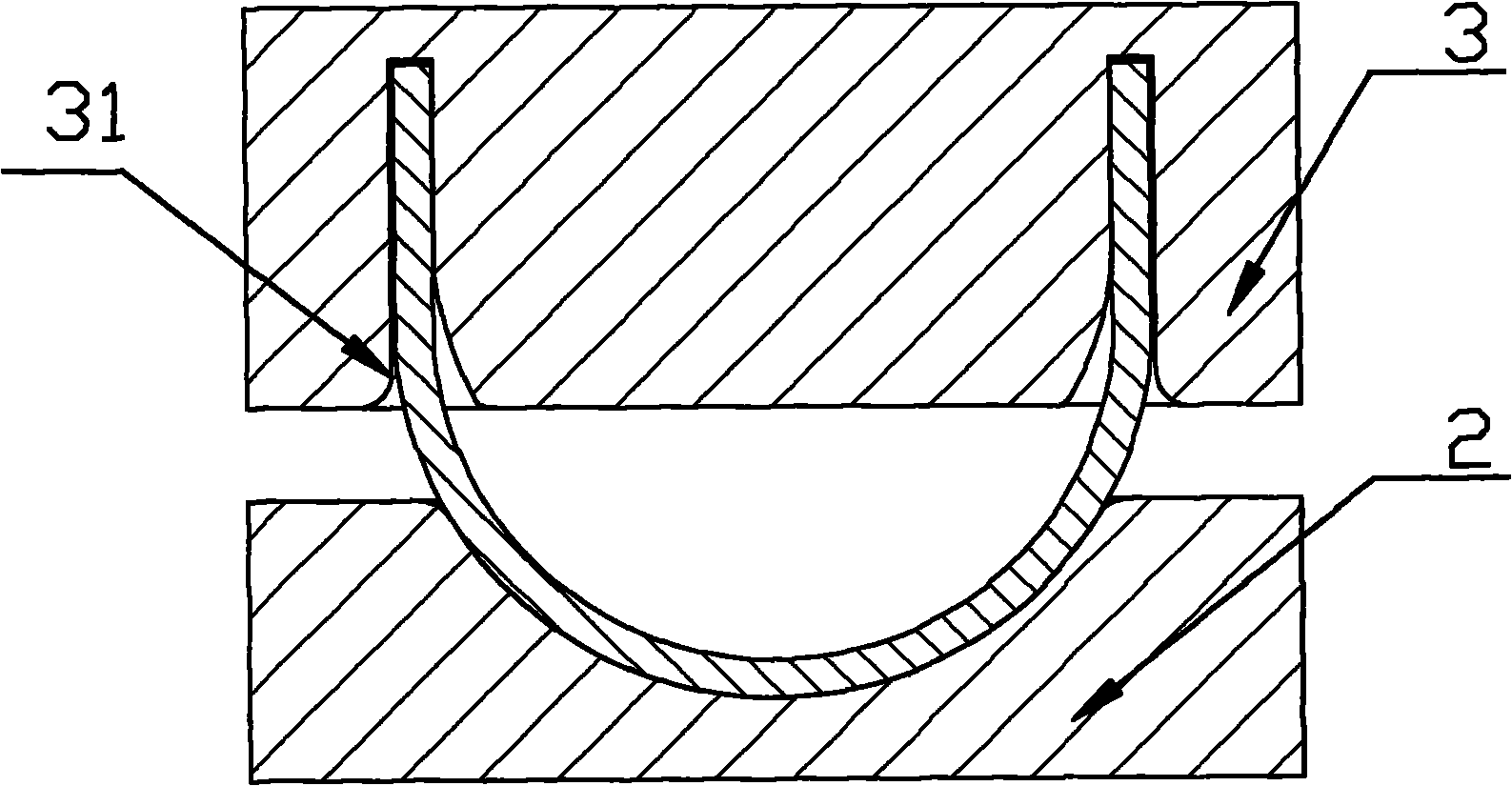

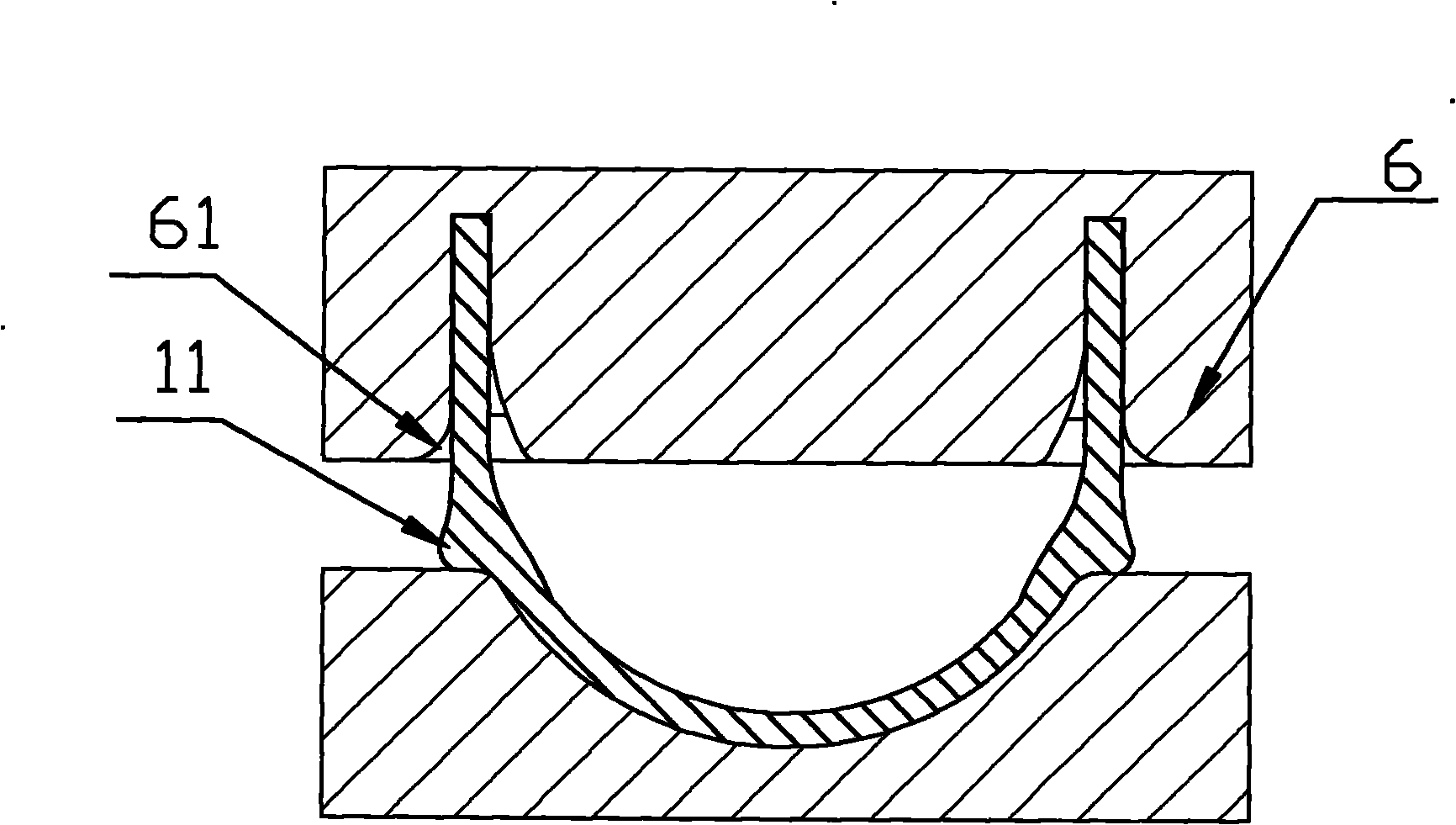

[0023] b. Flange upsetting: The flange upsetting process is divided into multiple upsetting, followed by the first upsetting: the center of the upsetting upper die 3 is aligned with the center of the upsetting lower die 2, and the upper side wall of the barrel blank 1 is just accommodated. In the longitudinal annular opening 31 of the upsetting upper die 3, the upsetting upper die 3 moves downward to the set position, so that the side wall of the barrel blank 1 forms an annular protrusion 11 along the upper end of the outer wall of the upsetting lower die 2; Second upsetting: the center of the second upsetting upper die 6 is aligned with the center of the upsetting lower die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com