Device for extracting metals or metal compounds from a material containing the metal or the metal compound

A technology of metal compounds and metals, which is applied in the field of devices for obtaining metals or metal compounds, and can solve problems such as heat loss and slag cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

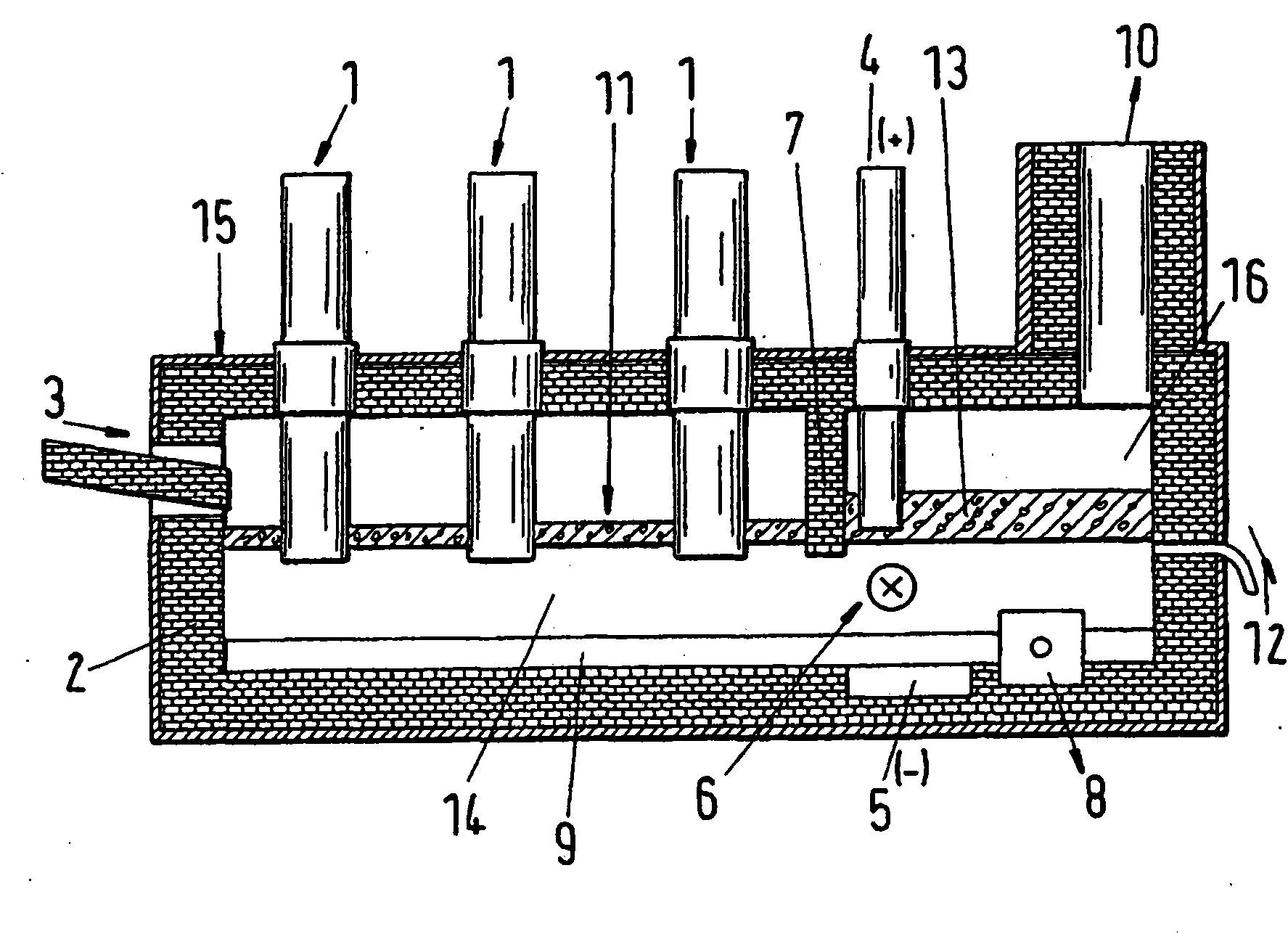

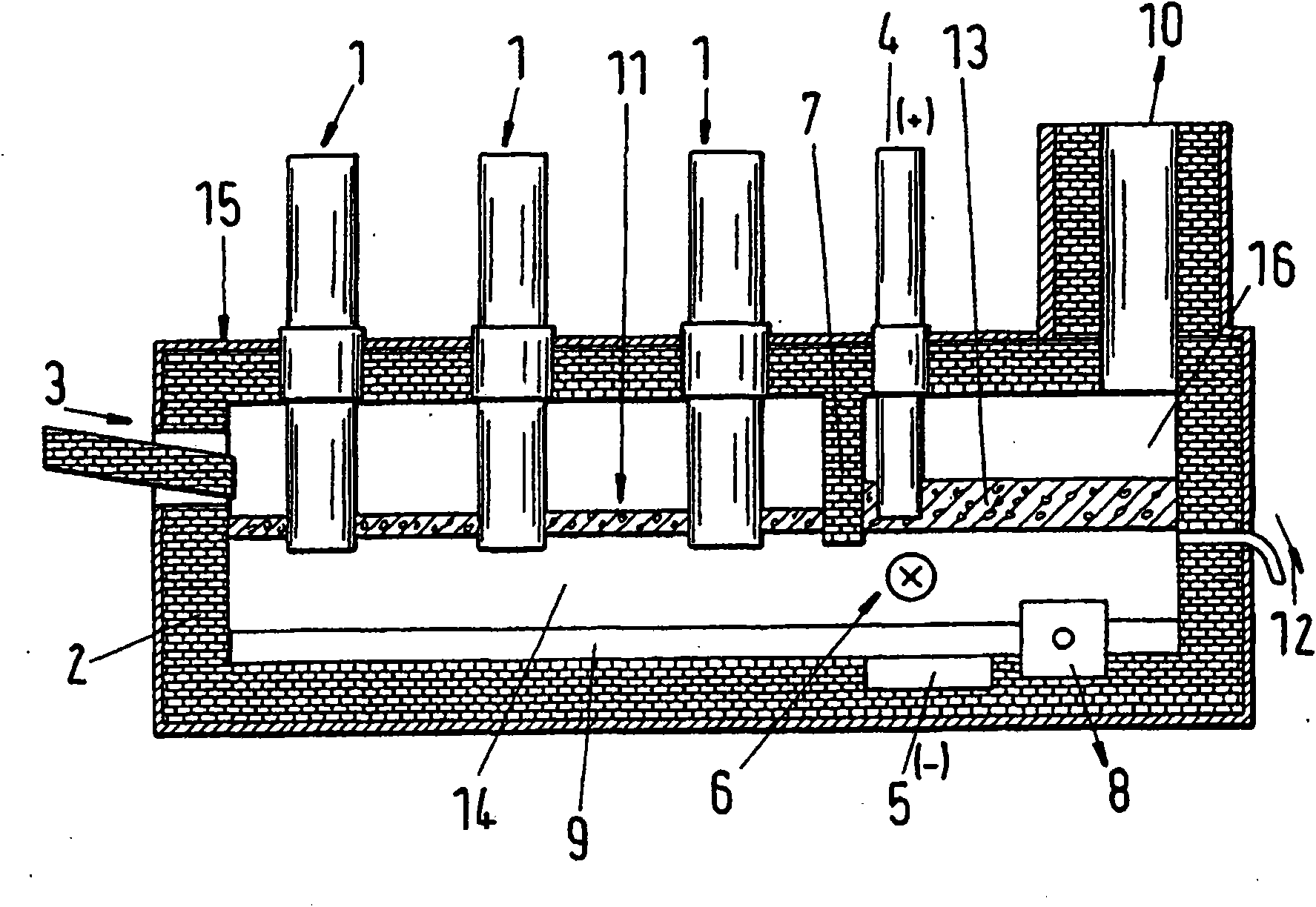

[0026] The embodiment comprises a combination of a conventional electric reduction furnace (SAF) of circular or polygonal design, usually operated with alternating current (AC), and a direct current (DC) reduction furnace with anodes and cathodes, giving the DC reduction furnace Supplemented with a permanent or electromagnet oriented transversely to the DC reduction furnace. Thus, in terms of process technology and according to the invention, the furnace combines a known electric reduction furnace and an enhanced slag cleaning furnace in one device.

[0027] Furnaces (intensified slag cleaning furnaces) of this type, denoted 15 , generally have three or six electrodes 1 arranged in rows or on a pitch circle in a circular or polygonal furnace chamber 2 . The medium (slag) 14 is supplied with the energy required for reduction, for melting and for deposition via these electrodes, usually operated with AC. However, the furnace is now configured differently from known furnaces in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com