LED driving method and LED driving circuit

A technology of light-emitting diodes and driving methods, which is applied to the layout of electric lamp circuits, light sources, electric light sources, etc., can solve the problems of low efficiency of light-emitting diodes and cannot be automatically adjusted, and achieve the effect of improving driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

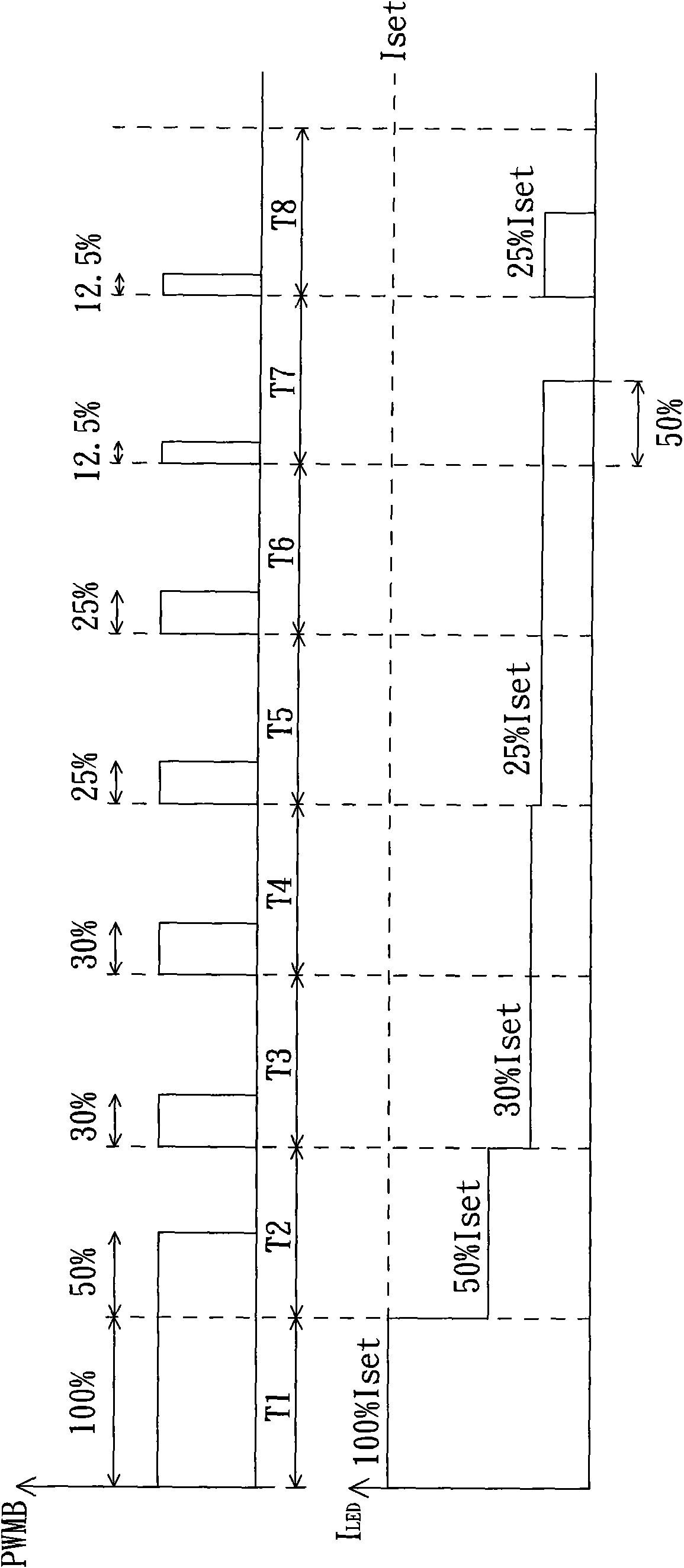

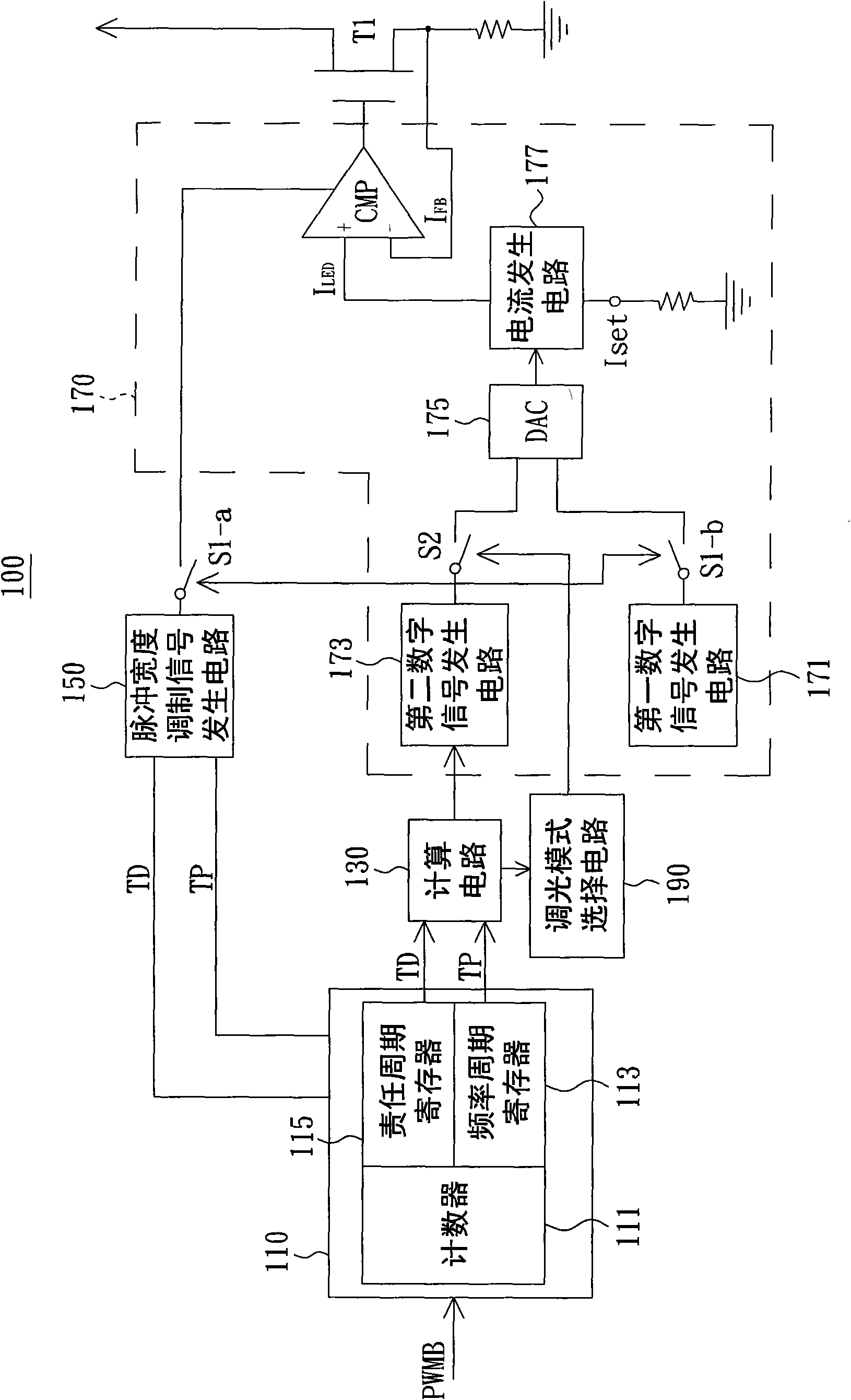

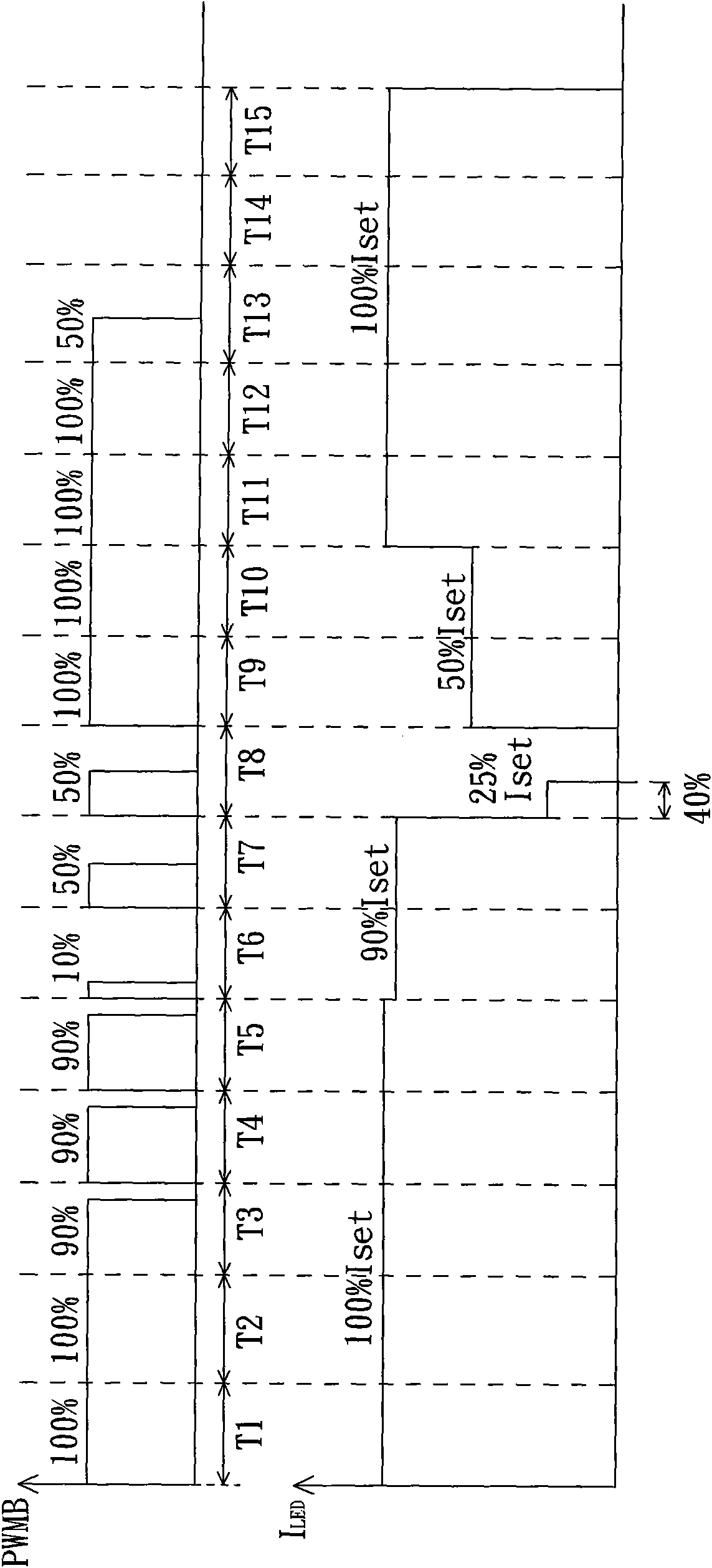

[0035] see figure 1 , which shows a timing diagram of a plurality of signals of a LED driving method according to an embodiment of the present invention. Here, the LED driving method in this embodiment can be applied to driving a backlight source of a non-self-illuminating display, but the present invention is not limited thereto. The following will combine figure 1 Each step of the light emitting diode driving method proposed by the embodiment of the present invention will be described in detail.

[0036] Specifically, the light emitting diode driving method of this embodiment may include the steps of: providing a pulse width modulation signal PWMB to determine the brightness of the light emitting diode, obtaining a duty cycle of the pulse width modulation signal PWMB, and according to the obtained duty cycle and the preset The relative size relationship of the critical value enables the LED to selectively work in the pulse width modulation dimming mode or the DC dimming mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com