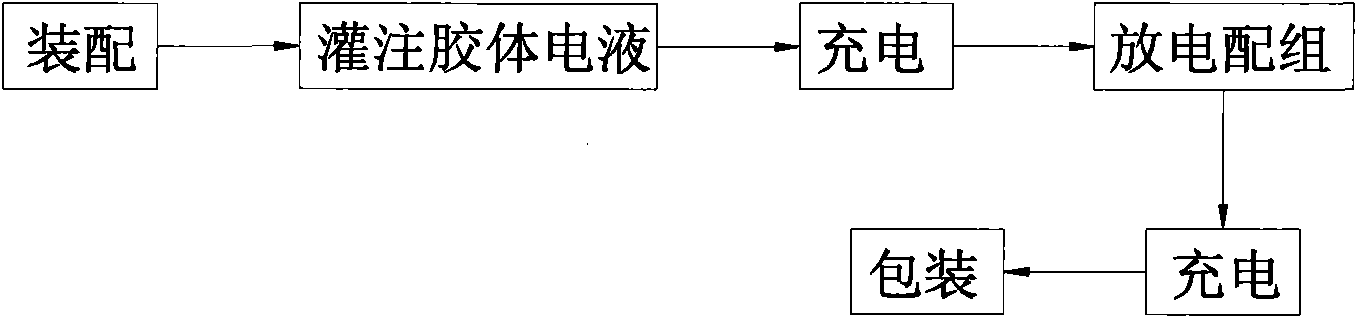

Internal formation process for high-capacity gel battery

A colloidal battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problems of short life, poor battery consistency, etc., to prolong service life, improve consistency, reduce Effect of waste acid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

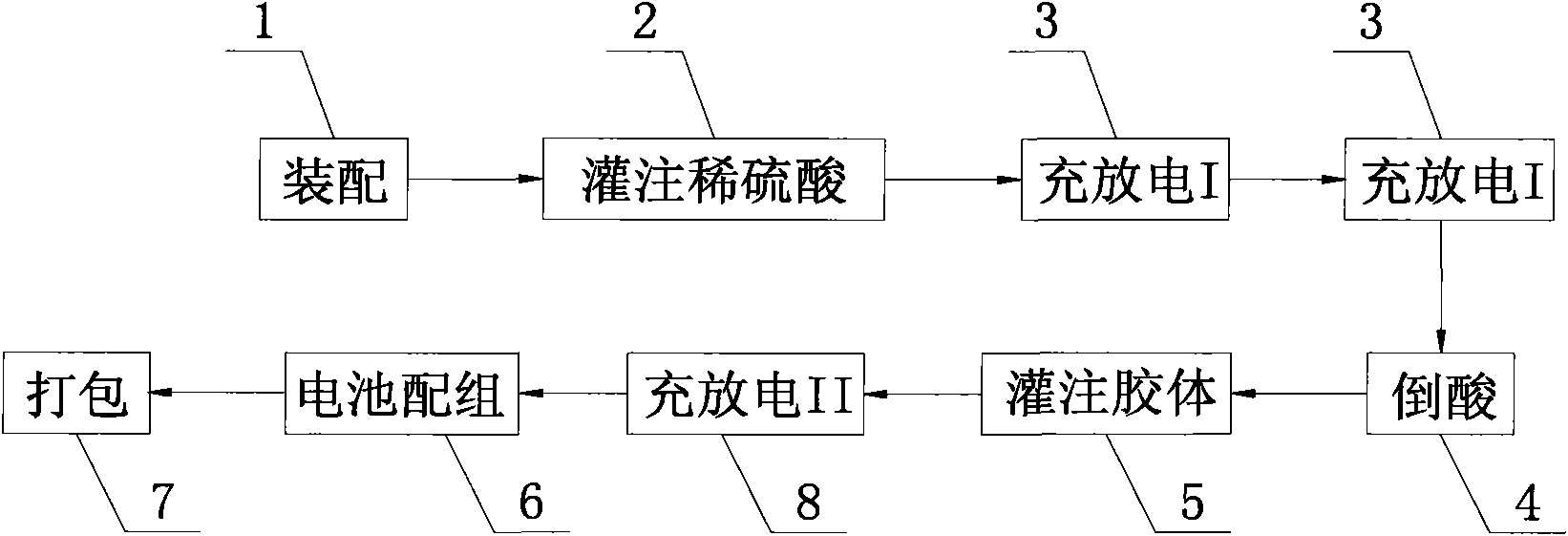

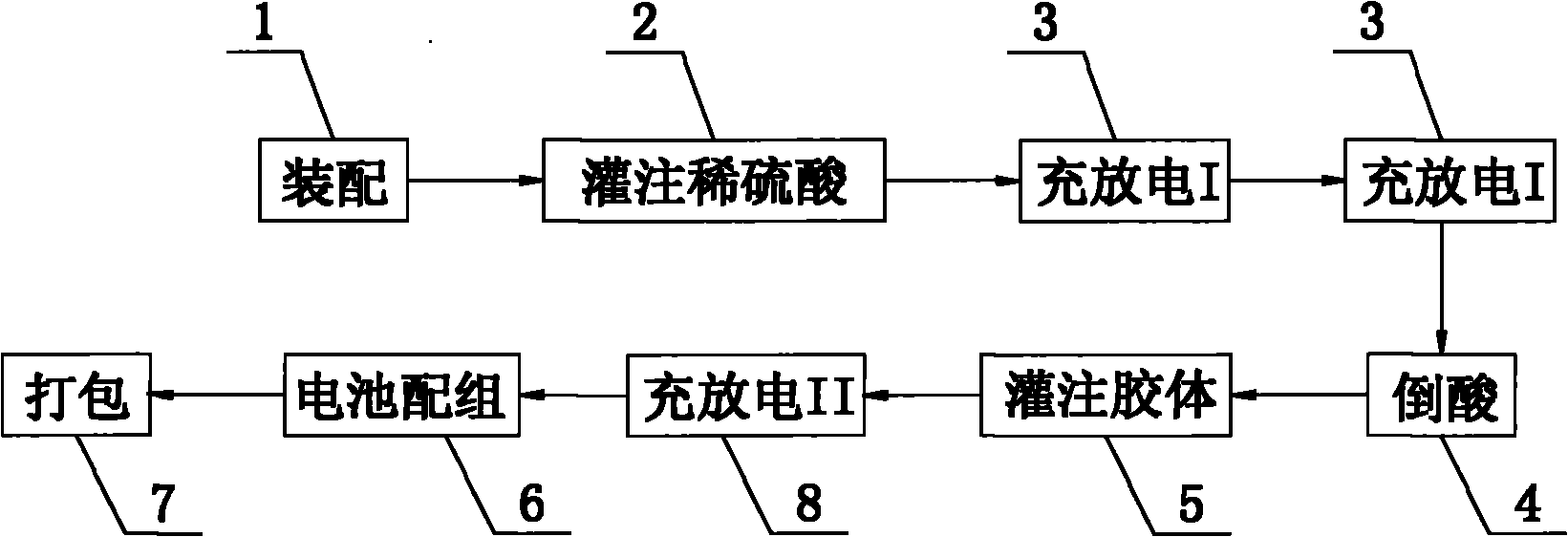

[0023] An internal formation process for a large-capacity colloidal battery, comprising the following steps in sequence:

[0024] A. Assembly 1: The polar plates after curing and drying are first assembled according to the weight, and the polar plates and separators are welded into a pole group through a special tooling fixture, put into a plastic case, and assembled into a non-liquid-injected Rechargeable Battery;

[0025] B. Infusion of dilute sulfuric acid 2: use concentrated sulfuric acid and water to prepare a density of 1.240g / cm 3 dilute sulfuric acid, then add 1% by weight sodium sulfate, 0.5% potassium sulfate, and 0.4% stannous sulfate, and pour it into the storage battery by vacuum injection;

[0026] C. Charge and discharge Ⅰ 3: charge and discharge twice, in the last discharge process, discharge the battery capacity to 105% of the rated capacity, and the discharge termination voltage is 9.60V ~ 10.50V;

[0027] D. Pour acid 4: Pour out excess acid;

[0028] E. ...

Embodiment 2

[0033] An internal formation process for a large-capacity colloidal battery, comprising the following steps in sequence:

[0034] A. Assembly 1: The polar plates after curing and drying are first assembled according to the weight, and the polar plates and separators are welded into a pole group through a special tooling fixture, put into a plastic case, and assembled into a non-liquid-injected Rechargeable Battery;

[0035] B. Infusion of dilute sulfuric acid 2: use concentrated sulfuric acid and water to prepare a density of 1.240g / cm 3 dilute sulfuric acid, then add 1.25% sodium sulfate, 0.1% potassium sulfate, and 0.6% stannous sulfate to it, and pour it into the storage battery by vacuum injection;

[0036] C. Charge and discharge 3: charge and discharge twice, in the last discharge process, discharge the battery capacity to 105% of the rated capacity, and the discharge termination voltage is 9.60V ~ 10.50V;

[0037] D. Pour acid 4: Pour out excess acid;

[0038] E. Per...

Embodiment 3

[0043] An internal formation process for a large-capacity colloidal battery, comprising the following steps in sequence:

[0044] A. Assembly 1: The polar plates after curing and drying are first assembled according to the weight, and the polar plates and separators are welded into a pole group through a special tooling fixture, put into a plastic case, and assembled into a non-liquid-injected Rechargeable Battery;

[0045] B. Infusion of dilute sulfuric acid 2: use concentrated sulfuric acid and water to prepare a density of 1.240g / cm 3 dilute sulfuric acid, then add 11.5% by weight sodium sulfate, 0.3% potassium sulfate, 0.2% stannous sulfate, and pour it into the storage battery by vacuum injection;

[0046] C. Charge and discharge 3: charge and discharge twice, in the last discharge process, discharge the battery capacity to 105% of the rated capacity, and the discharge termination voltage is 9.60V ~ 10.50V;

[0047] D. Pour acid 4: Pour out excess acid;

[0048] E. Per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com