Hoisting slide devices and hoisting slide equipment

A sliding device and hoisting technology, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of high rental cost of steel structure tower cranes, short tower crane service life, waste of manpower and material resources, etc., so as to facilitate popularization and use , Solve the difficulty of installation and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

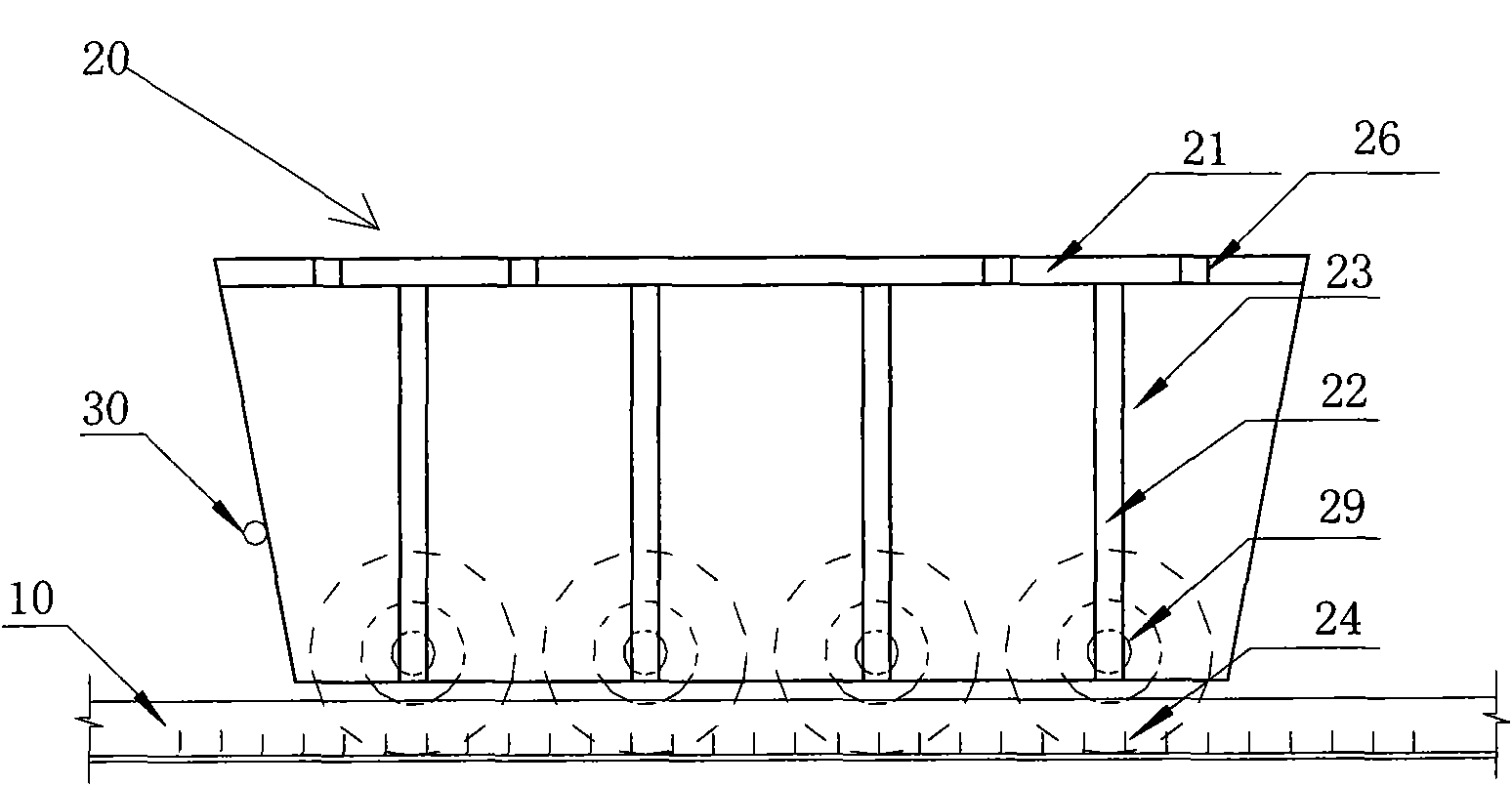

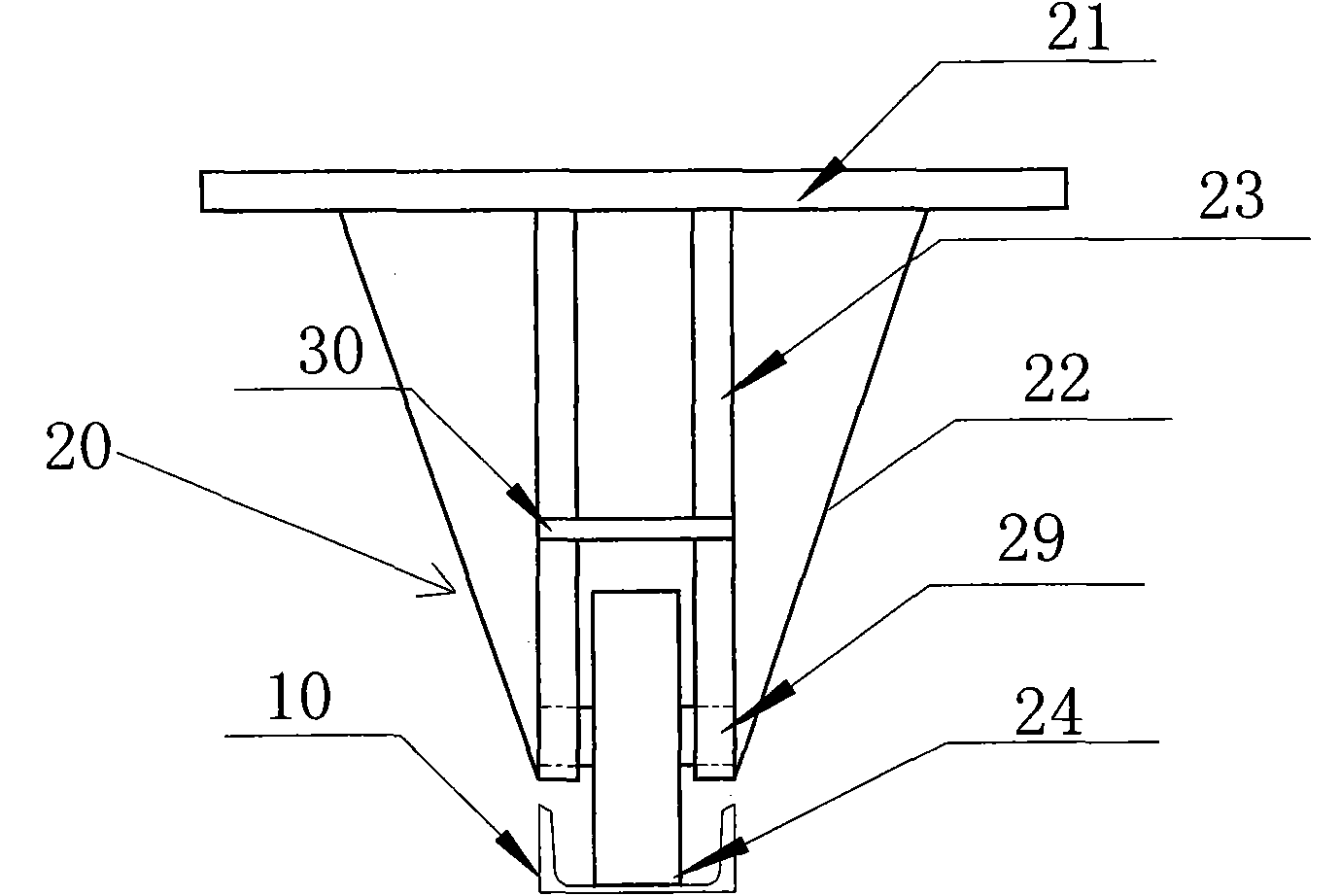

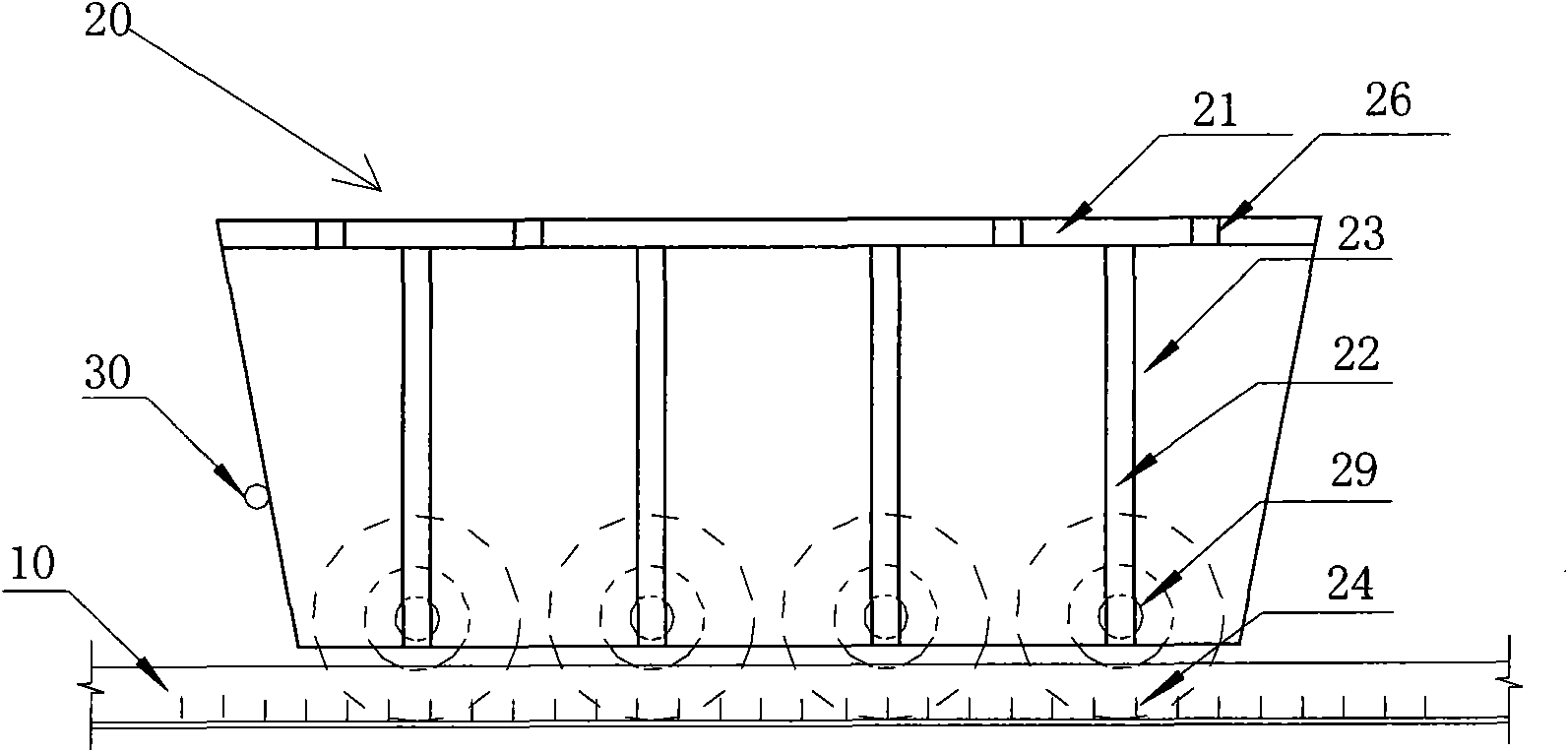

[0020] figure 1 It is a schematic diagram of the structure of the lifting and sliding device according to the present invention, combined with reference to figure 2 , as shown in the figure, the present invention provides a lifting and sliding device, comprising: a slide rail 10 and a bearing part 20 movably arranged on the slide rail 10 . The invention is simple in structure, easy to use, low in cost, easy to carry and easy to popularize and use.

[0021] see in conjunction figure 1 and figure 2 , Preferably, the slide rail 10 has a concave slideway; the bottom of the bearing part 20 is provided with a roller 24, and the roller 24 is arranged in the concave slideway. In this way, the structure is stable and easy to use.

[0022] see in conjunction figure 1 and figure 2 , preferably, the load-bearing part 20 also includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com