Composite luminescent film containing rare earth polyacid and brucite and preparation method thereof

A technology of luminescent film and rare earth polyacid, which is applied in the field of composite luminescent film containing rare earth polyacid and hydrotalcite and its preparation, to achieve the effect of strong operability, directional arrangement and uniform dispersion, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

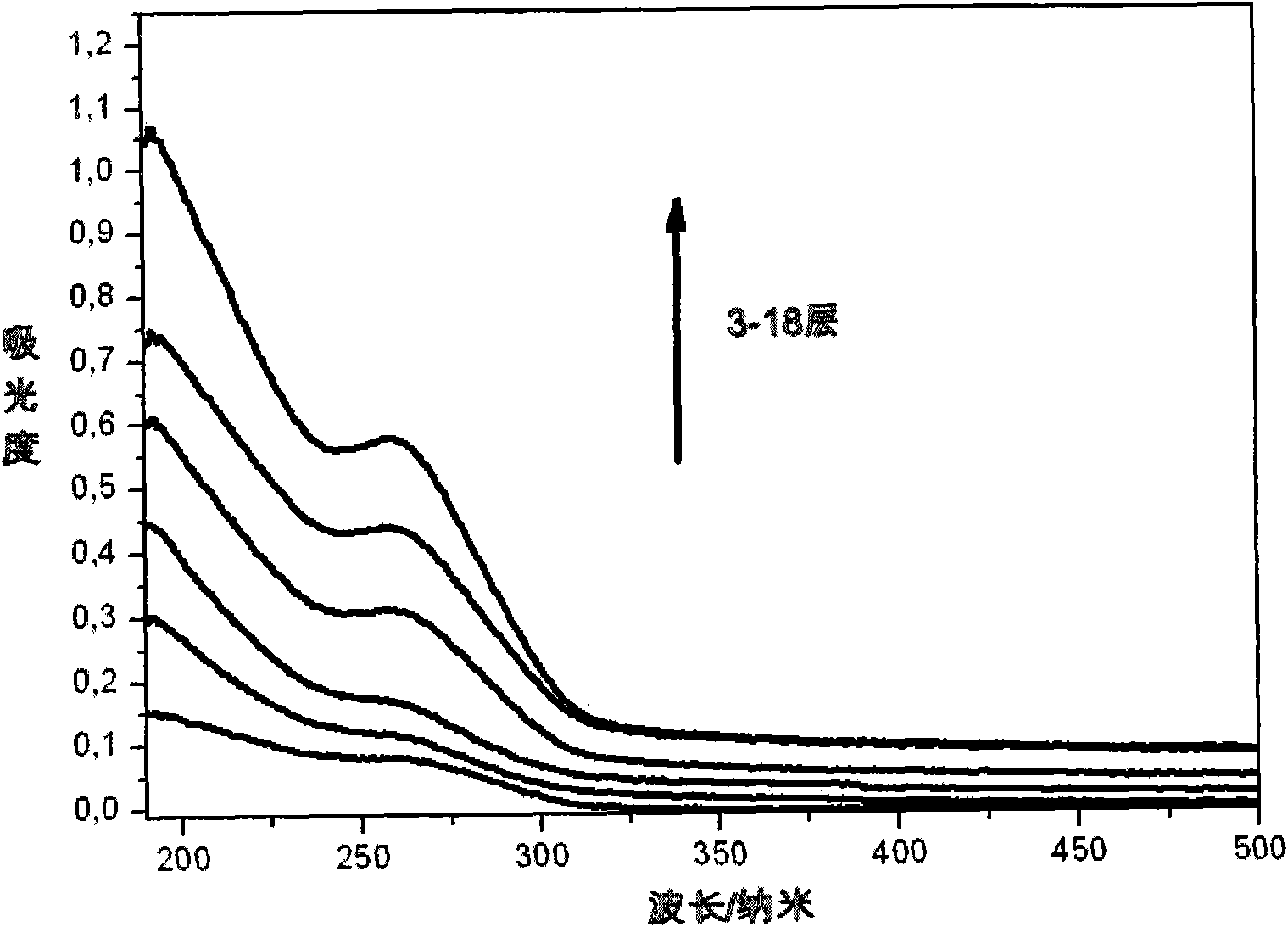

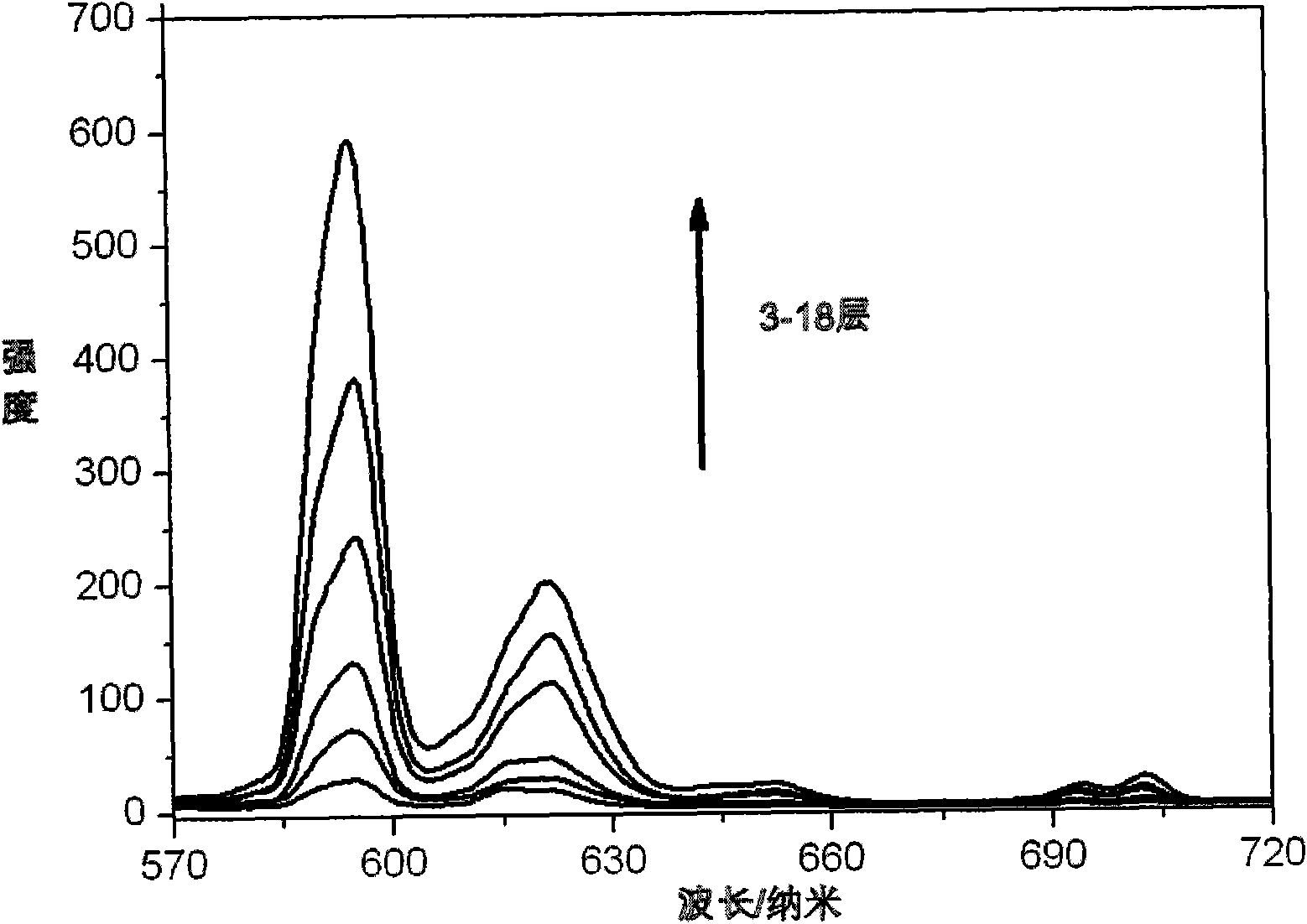

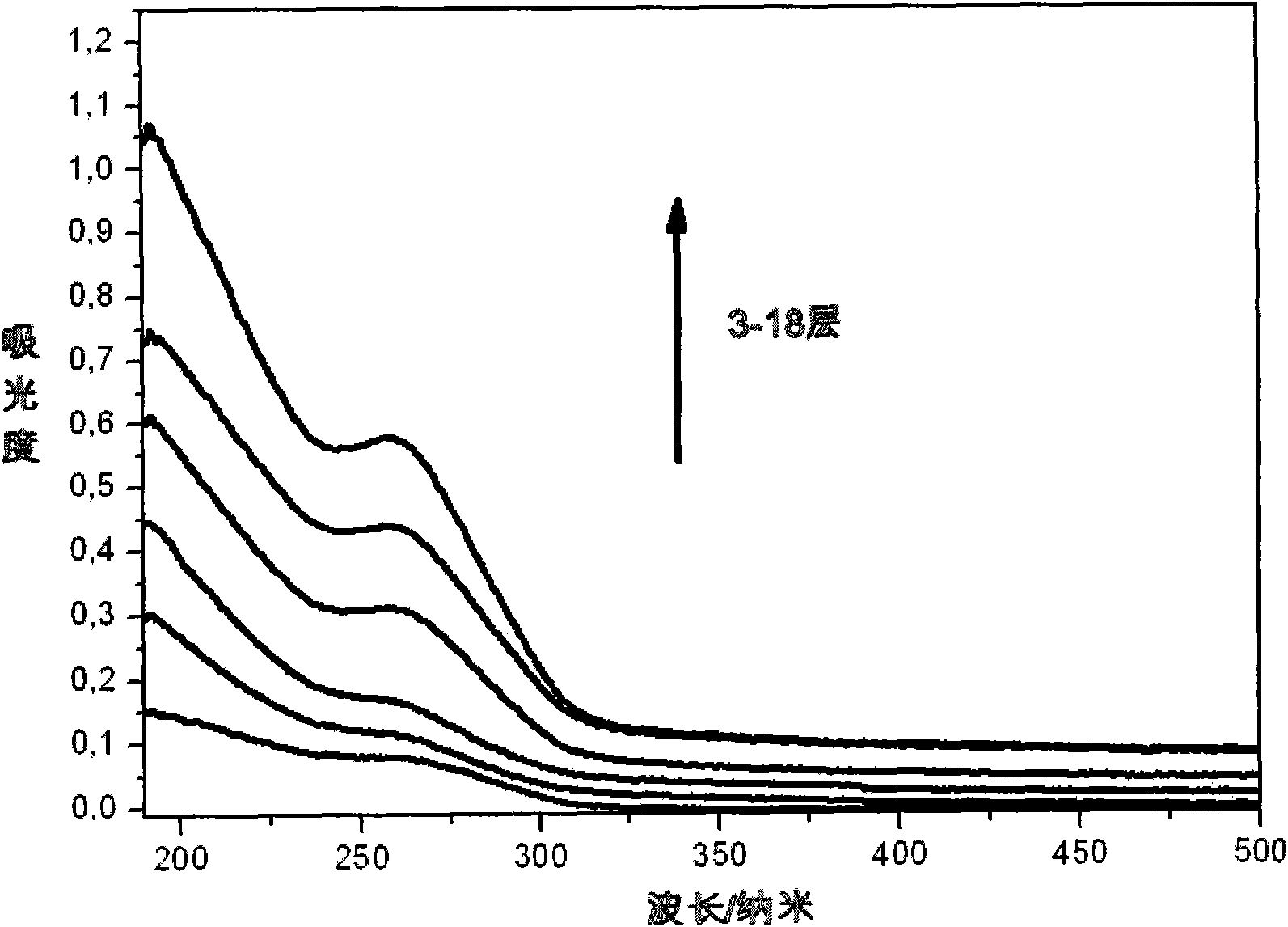

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of hydrotalcite precursor with nitrate between layers by ion exchange method:

[0023] a, 0.02mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.01mol of solid Al(NO 3 ) 3 ·6H 2 O and 0.026mol hexamethylenetetramine were dissolved in 70ml of deionized water, crystallized at 140°C for 24 hours in a 90ml PTFE pressure reactor, washed with deionized water, and dried at 70°C for 12h , to obtain carbonate intercalation hydrotalcite;

[0024] b. Dissolve 0.3g of the above-mentioned carbonate hydrotalcite and 63.75g of solid sodium nitrate in 300ml to remove CO 2 After uniform dispersion in deionized water, add 0.07ml of concentrated nitric acid, stir at 25°C under nitrogen atmosphere, carry out ion exchange reaction for 12 hours, and then use 2 Wash with deionized water until neutral, and dry at 70°C for 18 hours to obtain a hydrotalcite precursor with nitrate between layers.

[0025] 2. Take 0.1 g of the hydrotalcite precursor prepared in step 1 with nitrate betwe...

Embodiment 2

[0030] 1. Preparation of hydrotalcite precursor with nitrate between layers by ion exchange method:

[0031] a, 0.02mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.01mol of solid Al(NO 3 ) 3 ·6H 2 O and 0.026mol hexamethylenetetramine were dissolved in 70ml of deionized water, crystallized at 140°C for 24 hours in a 90ml polytetrafluoroethylene pressure reactor, washed with deionized water, and dried at 70°C for 12h , to obtain carbonate intercalation hydrotalcite;

[0032] b. Dissolve 0.3g of the above-mentioned carbonate hydrotalcite and 63.75g of solid sodium nitrate in 300ml to remove CO 2After uniform dispersion in deionized water, add 0.07ml of concentrated nitric acid, stir at 25°C under nitrogen atmosphere, carry out ion exchange reaction for 12 hours, and then use 2 Wash with deionized water until neutral, and dry at 70°C for 18 hours to obtain a hydrotalcite precursor with nitrate between layers.

[0033] 2. Take 0.1g of the above-mentioned nitrate intercalated hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com