Feeding and filtering device for homogenizer

A filter device and homogenizer technology, which is applied in filtration and separation, fixed filter element filters, mixers, etc., can solve the problems that the filter device cannot be disassembled, the function of the homogenizer is limited, and the function is single, so as to achieve humanized design, Reasonable structure and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

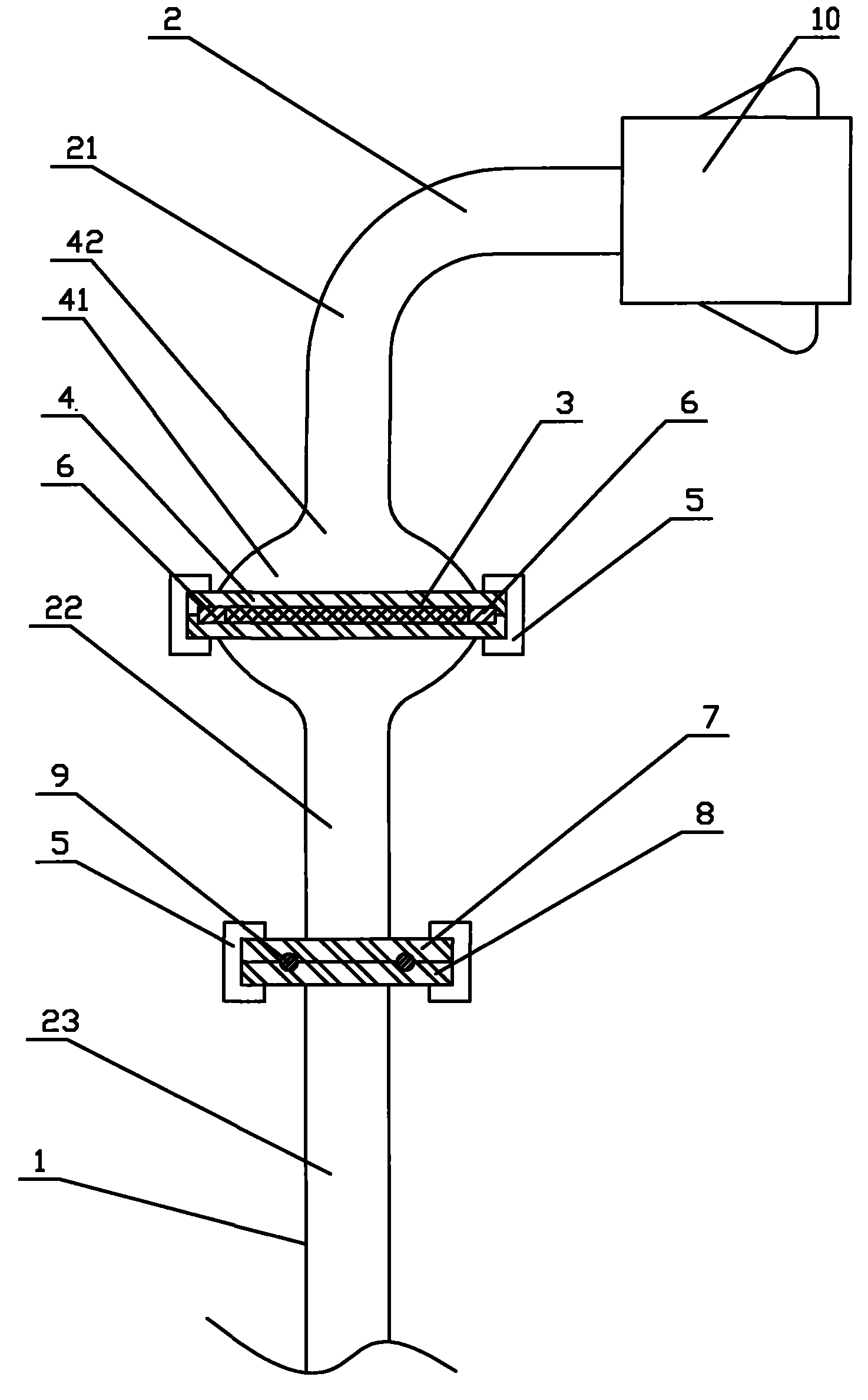

[0012] Such as figure 1 As mentioned above, the homogenizer feed filter device described in this embodiment mainly includes a conduit 1, which is provided with a filter screen 3, and the conduit 1 is formed by connecting three conduit bodies 2, wherein the first conduit body 21 and the second conduit body One end of the two conduit bodies 22 is provided with a filter head 4, the filter head 4 is divided into upper and lower two pieces, the filter screen 3 is clamped between the upper and lower two filter heads 4, and the upper and lower two filter heads 4 are fastened through the hoop 5 . And a gasket 6 is arranged between the upper and lower filter heads 4 . On the second conduit body 22, an end opposite to the filter head 4 and an end of the third conduit body 23 are provided with an upper clamp ring 7 and a lower clamp ring 8 that cooperate with each other to connect; the upper clamp ring 7 and the lower clamp ring 8 The clamps 5 are fastened together, and a sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com