High frequency plasma CVD apparatus, high frequency plasma CVD method and semiconductor thin film manufacturing method

A high-frequency plasma, plasma technology, applied in the ion CVD method. , In the field of ion CVD method, it can solve the problems of difficult uniform film formation, breakdown, leakage current, etc., and achieve the effect of good Raman spectral characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

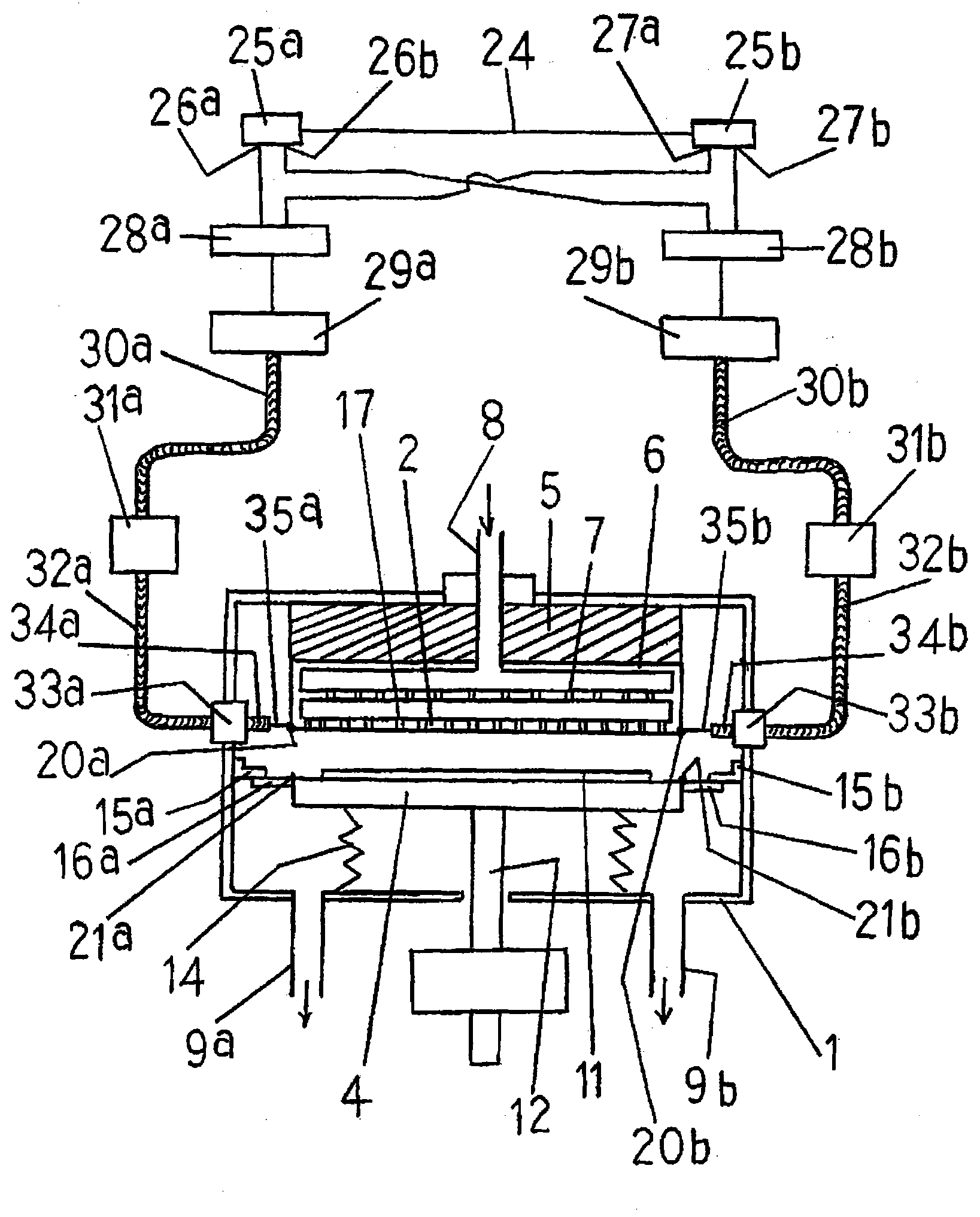

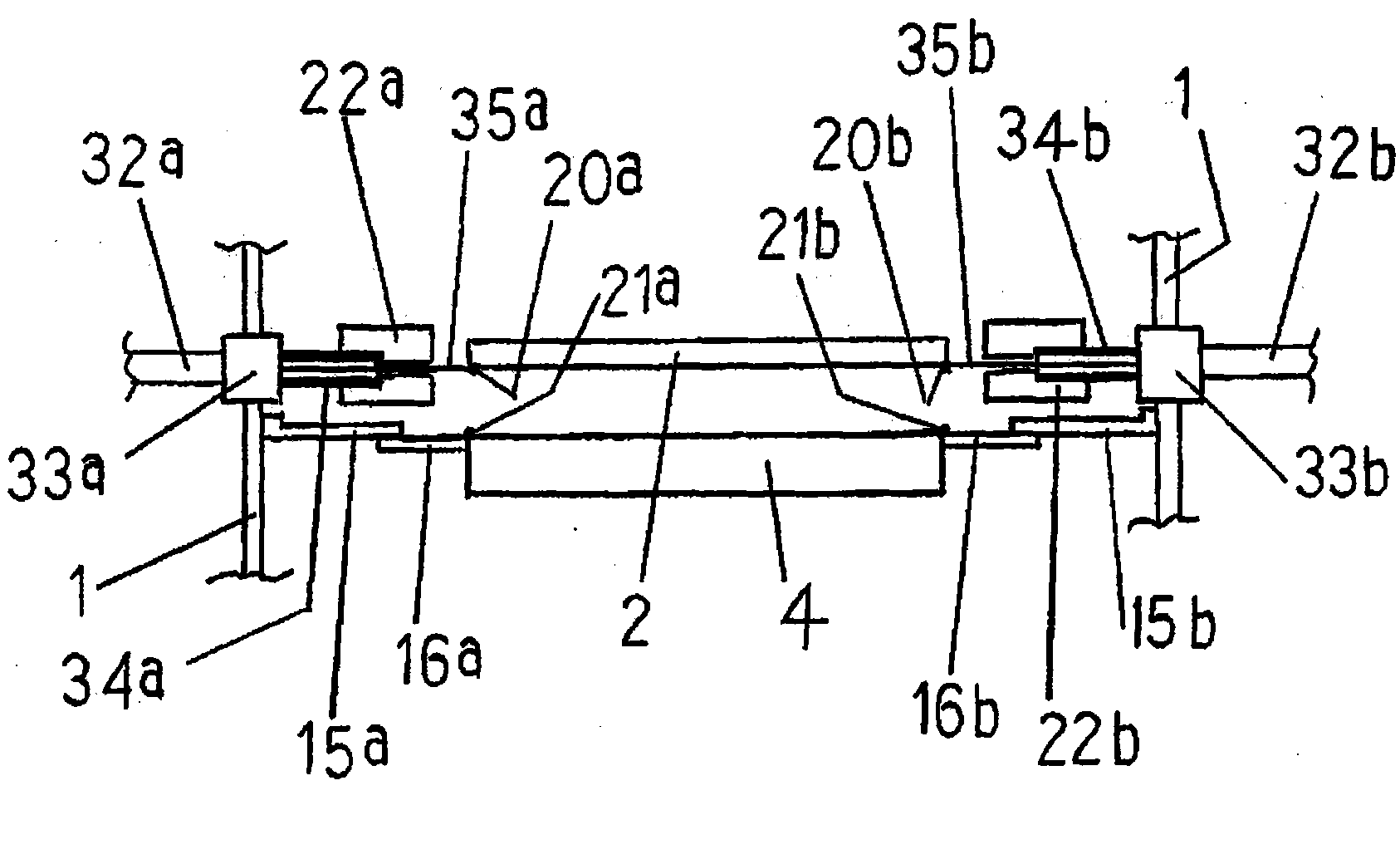

[0247] First, refer to Figure 1 to Figure 8 The plasma CVD apparatus and the plasma CVD method related to the first embodiment of the present invention will be described.

[0248] figure 1 It is a schematic diagram showing the whole plasma CVD apparatus related to the first embodiment of the present invention; figure 2 is to figure 1 An explanatory diagram of the structure of a power supply unit that supplies power to a pair of electrodes inside the plasma CVD apparatus shown; image 3 is to figure 1 A conceptual diagram of propagation of electric power supplied by a pair of electrodes inside the plasma CVD apparatus shown; Figure 4 is indicated by using figure 1 An explanatory diagram of an example of a method of adjusting power transmission when forming an i-type microcrystalline silicon film in the plasma CVD apparatus shown and performing power supply; Figure 5 is from figure 1 An explanatory diagram of a typical example of the pulse-modulated output output...

Embodiment 2

[0456] Next, refer to Figure 9 to Figure 11 A plasma CVD apparatus and a plasma CVD method related to the second embodiment of the present invention will be described.

[0457] Figure 9 It is a schematic diagram showing the whole of the plasma CVD apparatus related to the second embodiment of the present invention, Figure 10 is for figure 2 An explanatory diagram of a power supply device that supplies power to a pair of electrodes using a balun inside the plasma CVD apparatus shown, Figure 11 yes Figure 10 The shown conceptual diagram shows the flow of high-frequency current at a power supply device that supplies power to a pair of electrodes using a balun.

[0458] First, the configuration of the device will be described. However, the same reference numerals are assigned to the same components as those shown in the plasma CVD apparatus related to the first embodiment of the present invention described above, and description thereof will be omitted.

[0459] First,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com