Refrigeration device

A refrigeration device and refrigerant technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficult liquid-phase refrigerants, equal distribution, and large volume of gas-phase refrigerants, and achieve improved cooling performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

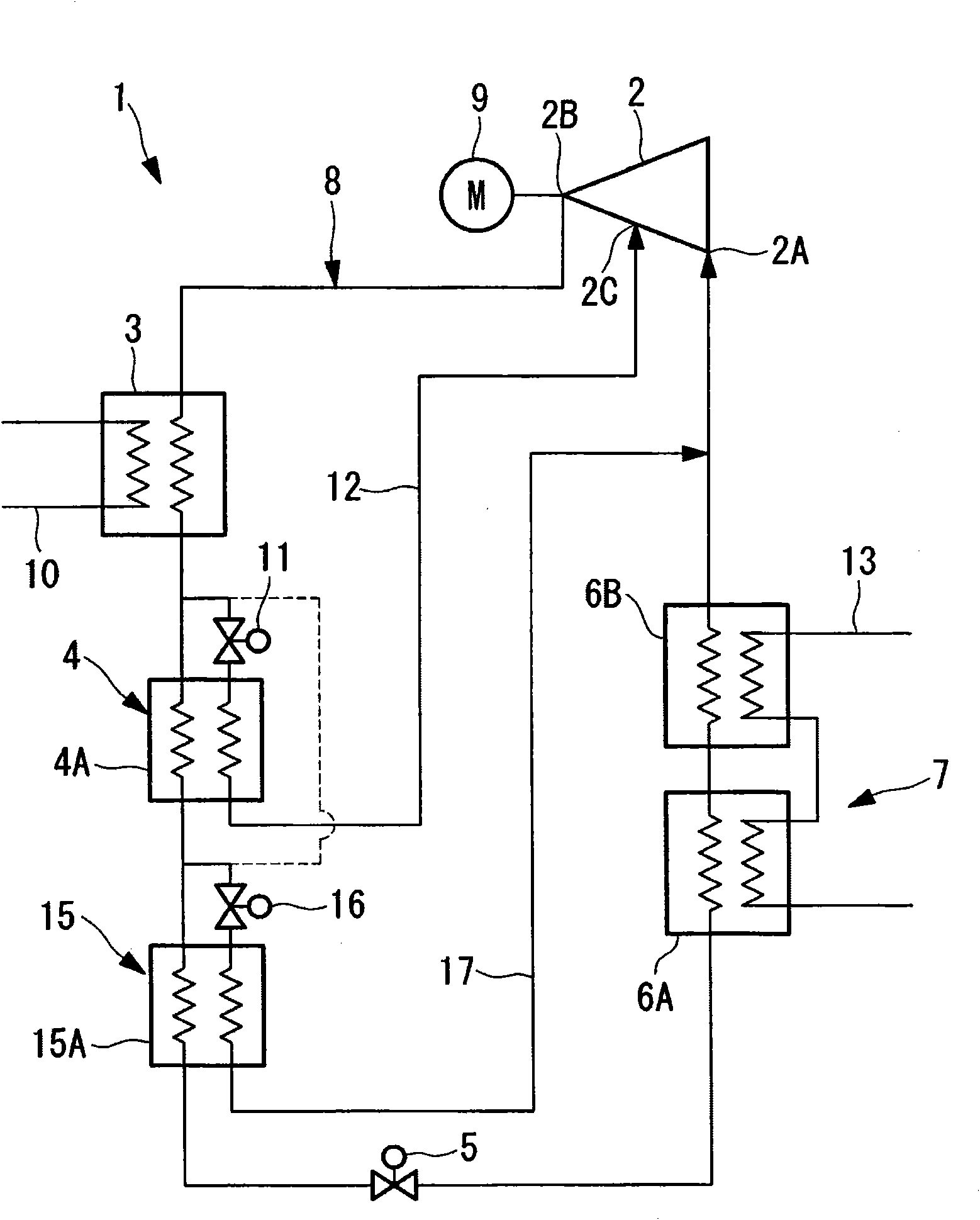

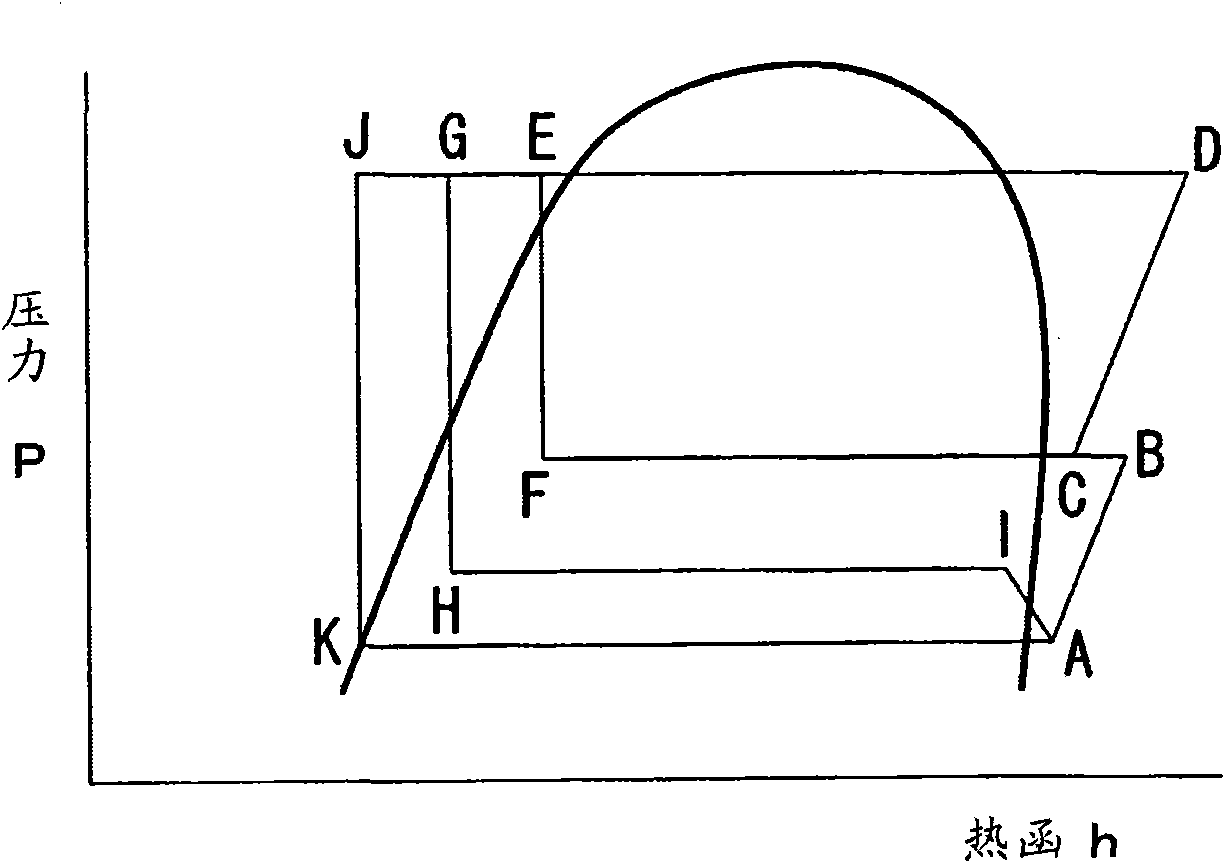

[0051] Below, use Figure 1 to Figure 3 A first embodiment of the present invention will be described.

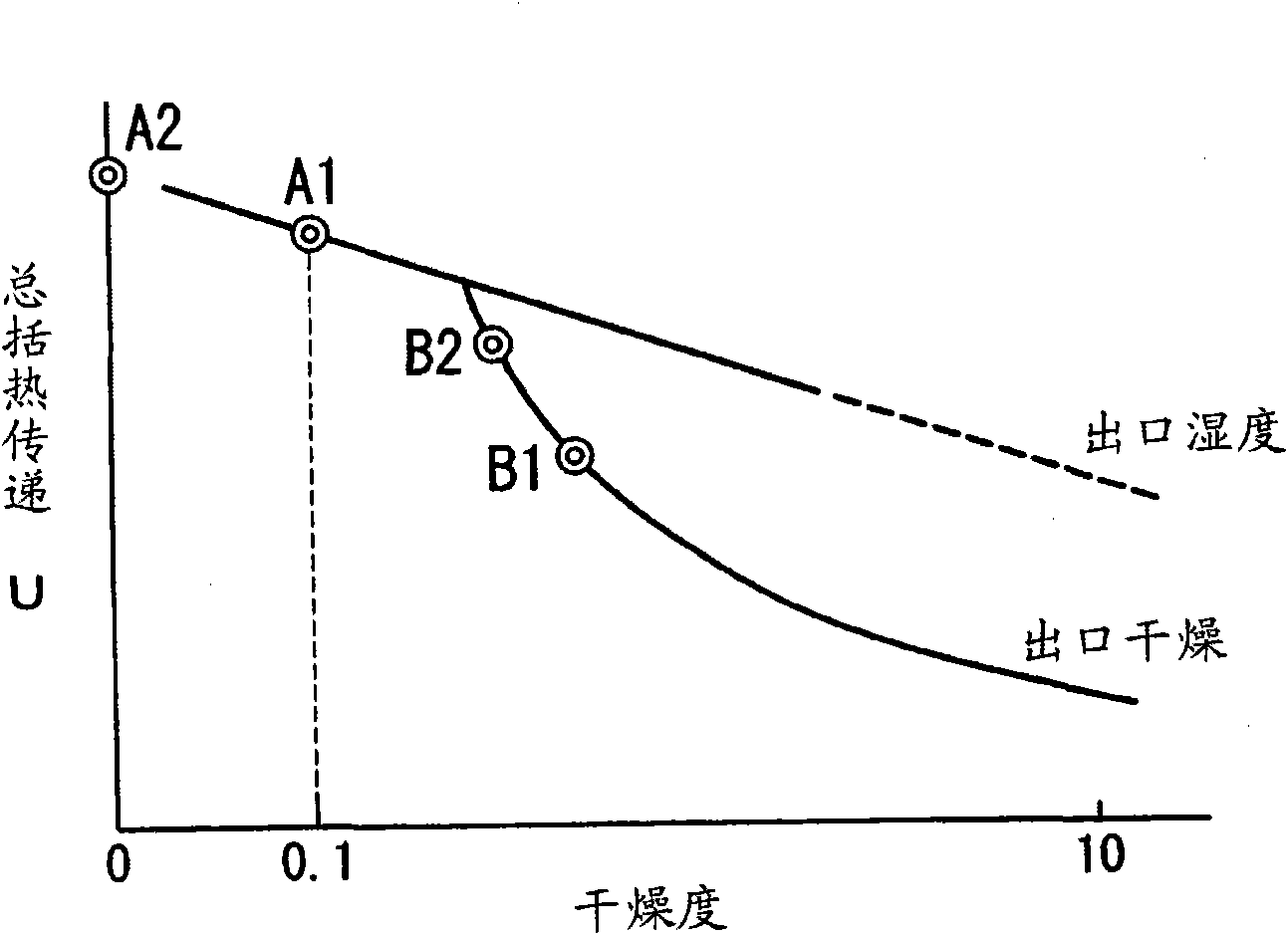

[0052] figure 1 It shows the refrigerating cycle diagram of the turbo refrigerating device according to the first embodiment of the present invention. The turbo refrigeration device 1 has a refrigeration cycle 8 that is connected in sequence by the following components to form a closed circuit. The refrigeration cycle 8 includes: a secondary turbo compressor 2, a condenser 3, an economizer 4, a main expansion valve 5, and two plate heat exchangers. The evaporator 7 constituted by multi-stage connection of the exchangers 6A and 6B in series.

[0053] The two-stage turbo compressor 2 is a multi-stage compressor driven by an inverter motor 9, and has an intermediate suction port 2C provided between a first impeller and a second impeller (not shown in the drawing) in addition to the suction port 2A and the discharge port 2B. , the low-pressure refrigerant gas sucked from the...

no. 2 example

[0072] Use below Figure 4 A second embodiment of the present invention will be described.

[0073] Compared with the above-mentioned first embodiment, this embodiment is different in the structure of the refrigerant pre-cooler 25 . The description of the other points is omitted since they are the same as those of the first embodiment.

[0074] In this embodiment, the refrigerant precooler 25 is constituted by a gas-liquid separator 25A provided on the inlet side of the evaporator 7 (plate heat exchanger 6A). The gas-phase refrigerant separated by the gas-liquid separator 25A returns to the refrigerant suction circuit between the evaporator 7 and the two-stage turbo compressor 2 through the gas circuit 26 having the on-off valve 27 ,

[0075] As described above, even if the refrigerant precooler 25 composed of the gas-liquid separator 25A is provided on the inlet side of the evaporator 7 (plate heat exchanger 6A), it is possible to supply the dryness to the evaporator 7 (pla...

no. 3 example

[0078] Use below Figure 5 A second embodiment of the present invention will be described.

[0079] Compared with the above-mentioned first embodiment, this embodiment is different in the structure of the refrigerant pre-coolers 35 and 36 . The description of the other points is omitted since they are the same as those of the first embodiment.

[0080] Compared with the evaporator 7 composed of a plurality of plate heat exchangers 6A and 6B connected in series and in multiple stages, in this embodiment, the inlets of the plate heat exchangers 6A and 6B are arranged in series and in multiple stages, and are respectively composed of gas-liquid separators 35A and 36A. Refrigerant precoolers 35, 36. The gas-phase refrigerant separated by the respective gas-liquid separators 35A, 36A returns to the refrigerant suction circuit between the evaporator 7 and the two-stage turbo compressor 2 via the gas circuits 37 , 39 having the on-off valves 38 , 40 .

[0081] As described above, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com