Camera module

A camera module and lens module technology, applied in the field of camera modules with an optical anti-shake function, can solve the problems of increasing the total height of the camera module, increasing the manufacturing cost of the camera module, and unfavorable thinning of the camera module. Achieve the effect of reducing height, saving cost and eliminating image blur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The camera module of the technical solution will be further described in detail below in conjunction with the drawings and multiple embodiments.

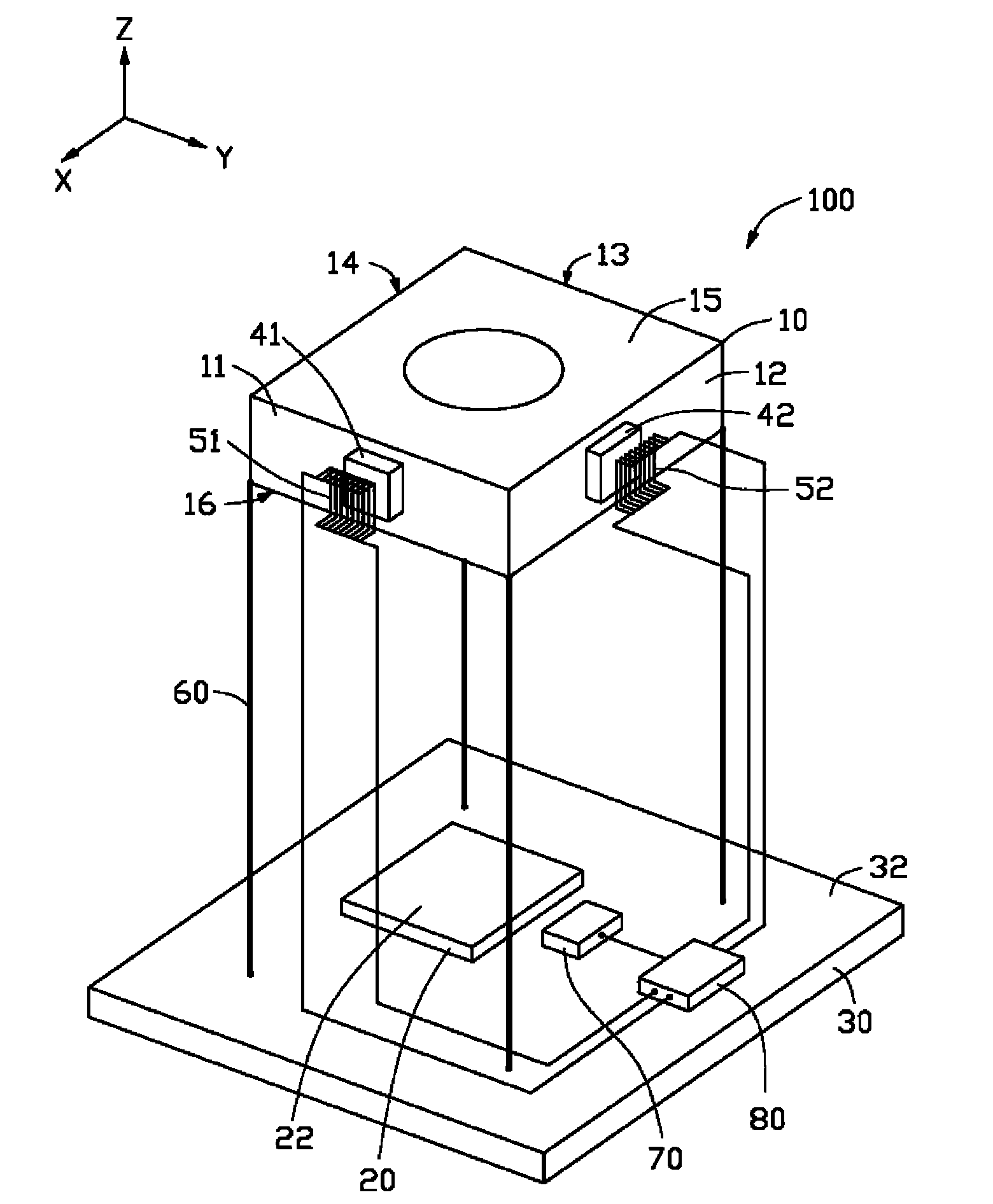

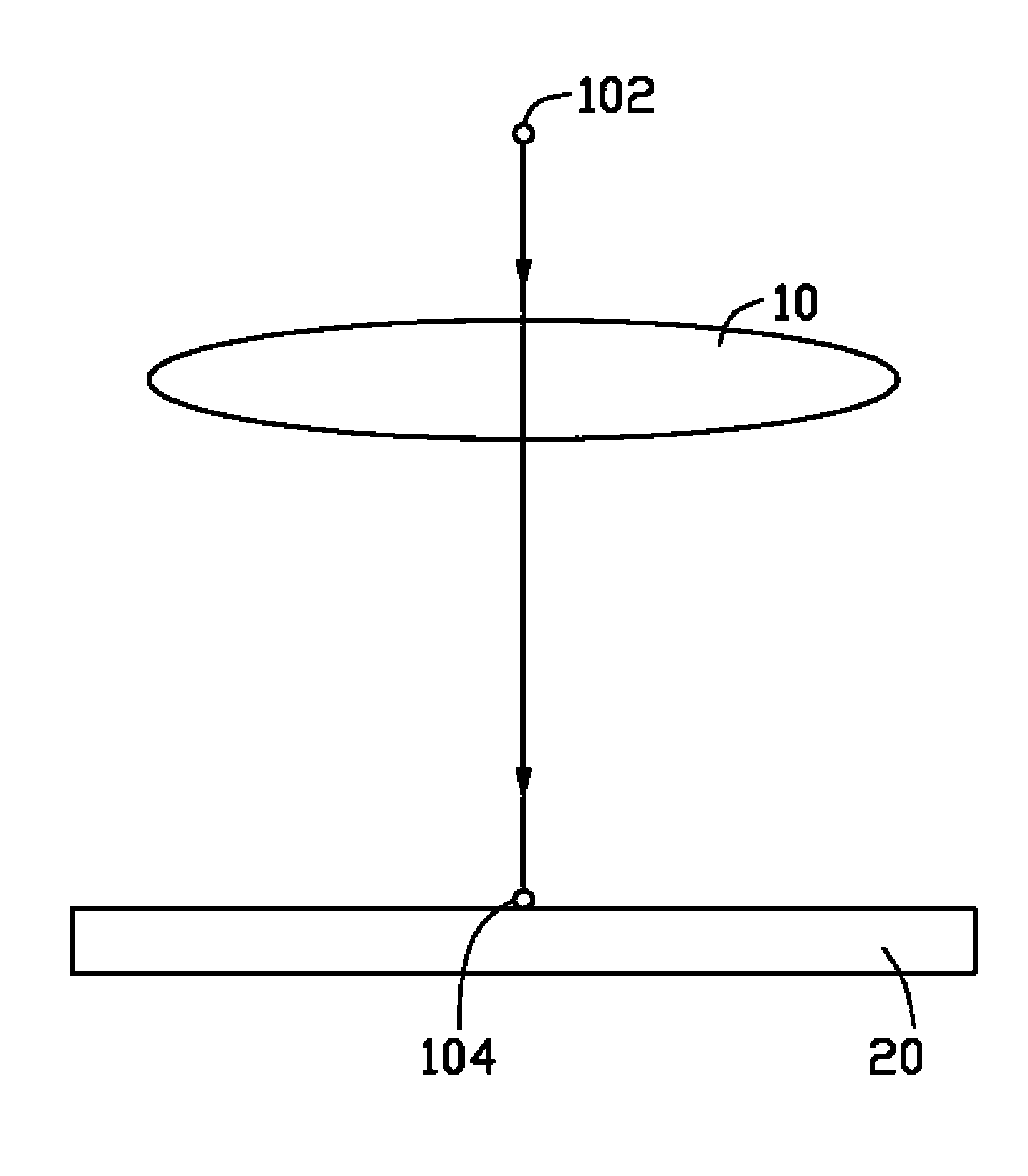

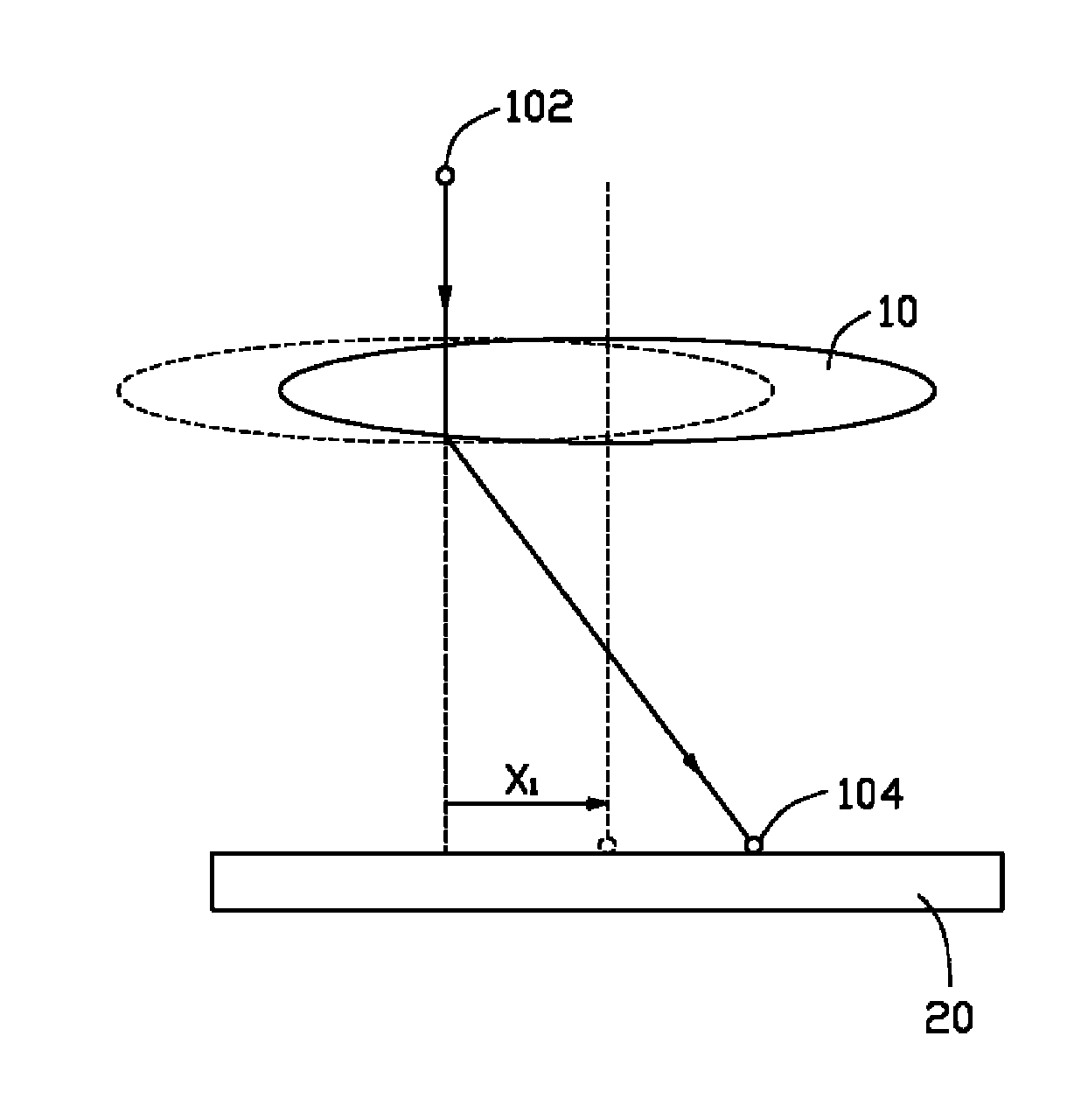

[0016] see figure 1 The optical image stabilization camera module 100 provided in the first embodiment of the technical solution includes a circuit board 30, an image sensor 20, a displacement sensor 70, a processor 80, a lens module 10, a flexible support body 60, a first Magnet 41 , second magnet 42 , first wire 51 , second wire 52 .

[0017] The circuit board 30 has a surface 32 on which the image sensor 20 , the displacement sensor 70 and the processor 80 are disposed, and the image sensor 20 and the displacement sensor 70 are fixed relative to the circuit board 30 . The lens module 10 is opposite to the image sensor 20 . The image sensor 20 has an image sensing surface 22 perpendicular to the optical axis of the lens module 10 . One end of the flexible supporting body 60 is connected to the surface 32 , and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com