Coreless wooden heat-insulating fireproof door

A technology of fire doors and inorganic fire boards, applied in fire doors, door leaves, ventilation layout, etc., can solve the problems of increased door weight, increased operating burden, waste of materials, etc., and achieves high structural strength, prevents temperature rise, and is easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings. The present invention can be single leaf door, also can be combination door.

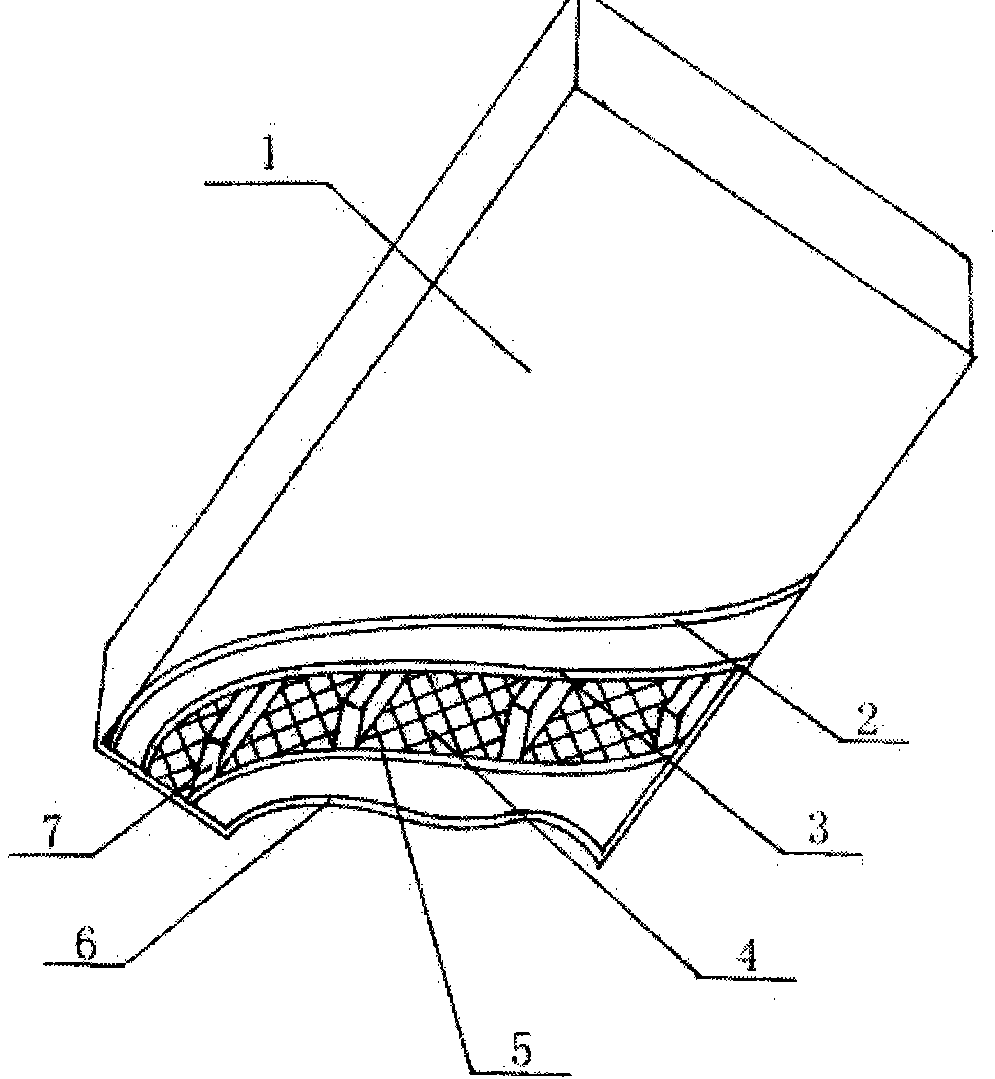

[0048] Such as Figure 4 As shown, a wooden heat-insulated fire door is provided here, including a door leaf 1 and a door frame 2, and a fireproof lock 8 is installed on the door leaf 1.

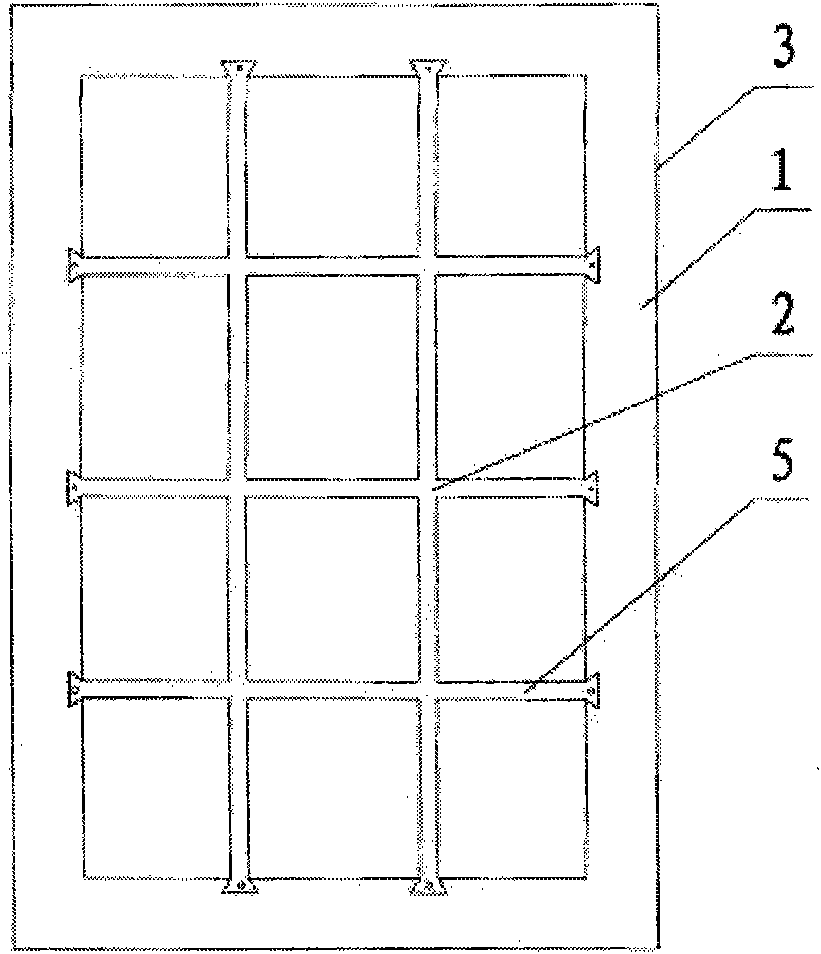

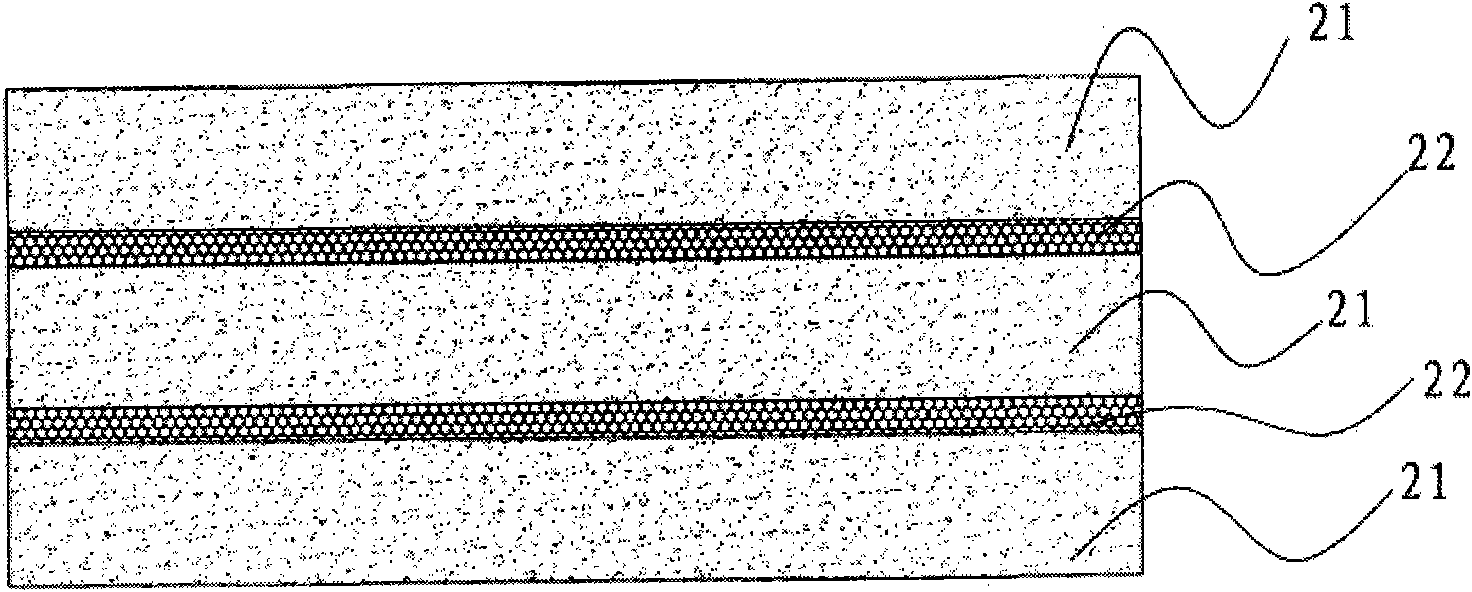

[0049] Then the door leaf 1 includes a door leaf skeleton in terms of composition, and the formation of the door leaf skeleton includes the skeleton 7 arranged on both sides and the middle skeleton 10 provided between the skeleton 7, such as Figure 6 shown. And the glass magnesium inorganic fireproof board 5 is pressed on both sides of the door frame, and the outer surface of the glass magnesium inorganic fireproof board 5 is covered with a flame-retardant plywood 4, such as Figure 5 . The two sides of the door leaf 1 respectively form the fire-receiving surface and the back-fire surface. When conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com