Solar silicon slice cleaning agent and method for preparing same

A technology for solar silicon wafers and cleaning agents, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems affecting device quality and yield, inappropriate solution concentration, black surface of silicon wafers, etc. To solve the problem, to achieve the effect of complete dissolving scale, cheap and easy-to-obtain chemicals, and strong ability to remove oil and stubborn scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

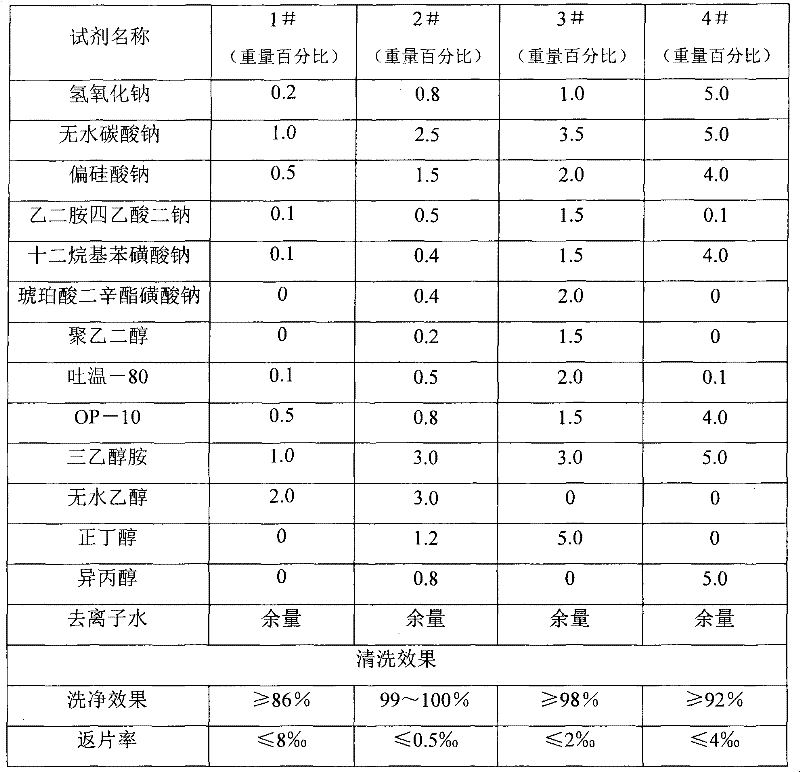

Examples

Embodiment Construction

[0015] 1. Cleaning solution preparation steps:

[0016] 1. Dissolve an appropriate amount of sodium hydroxide in deionized water to make an alkaline solution, then mix 1-5% sodium carbonate and 0.5-4% sodium silicate and dissolve them in the above-mentioned warm water to obtain a mixed solution.

[0017] 2. Add 0.1-1.5% chelating agent disodium ethylenediamine tetraacetate into the above mixed solution and stir evenly to prepare solution A.

[0018] 3. Add 0.1-4% of anionic surfactant sodium dodecylbenzene sulfonate, 0.4-2% dioctyl sodium sulfosuccinate, 0-1.5% of non-ionic surfactant polyethylene glycol, 0.1 ~2% of non-ionic surfactant Tween-80, 0.5-4% of non-ionic surfactant OP-10 were dissolved in deionized water and stirred evenly to prepare solution B.

[0019] 4. Mix 1-5% additive triethanolamine and 2-5% organic solvent absolute ethanol or n-butanol or isopropanol to prepare solution C.

[0020] 5. Dissolve solution B in solution C and mix well, then add the mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com