Fixed bed multistage reactor for aromatizing reaction of olefin-containing liquefying gas

A reactor and liquefied gas technology, applied in the field of catalytic conversion reactors, can solve problems that do not involve multi-bed reactor equipment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

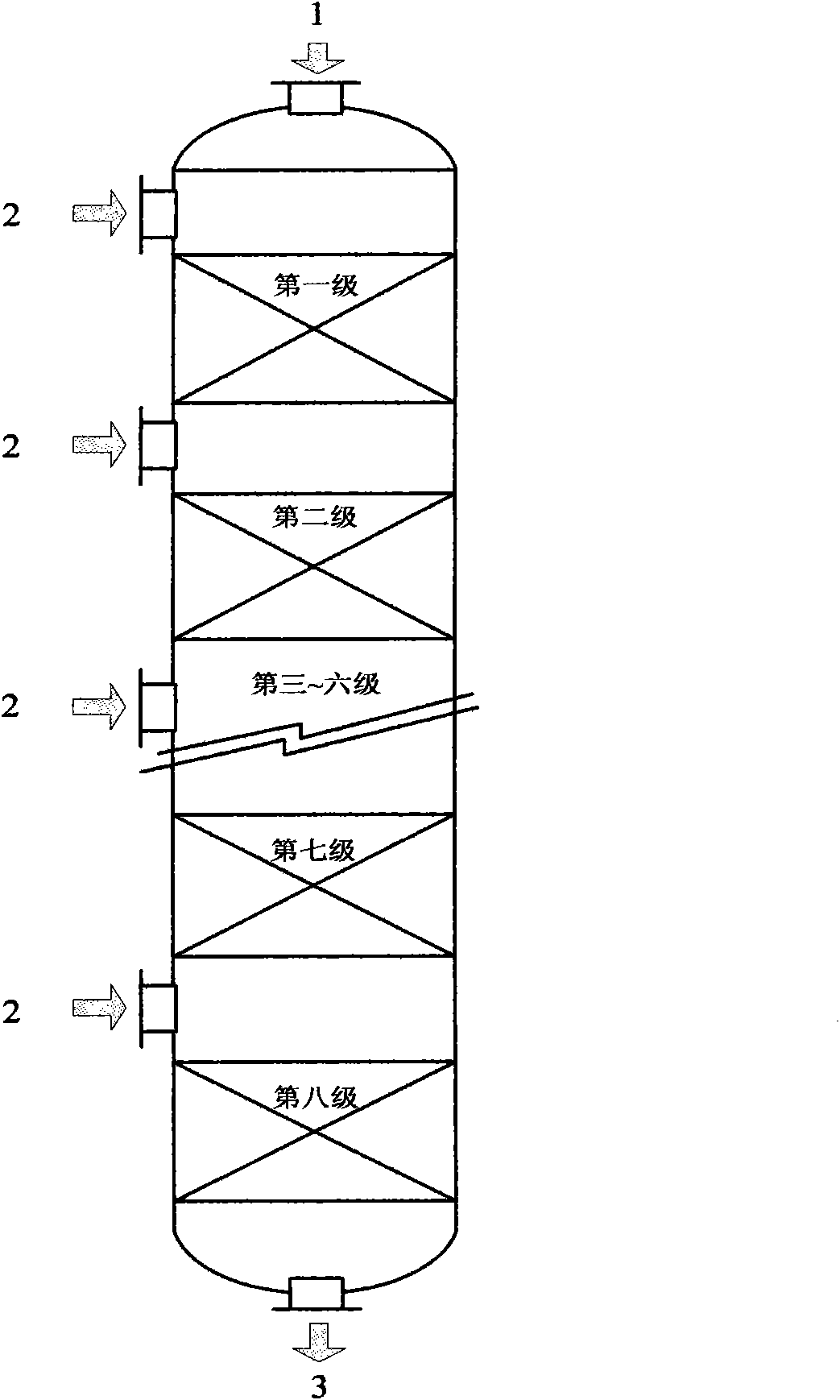

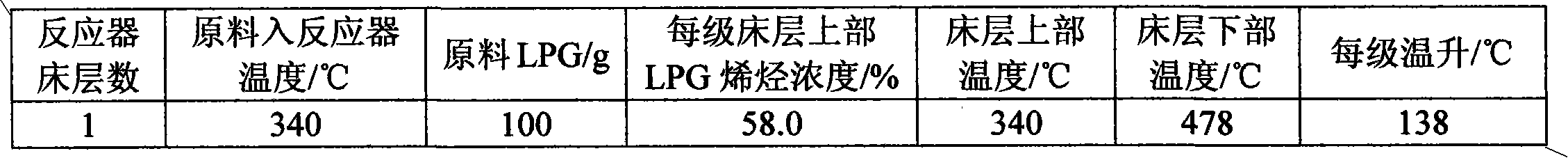

[0030] Low-temperature production of gasoline from liquefied gas: When the concentration of olefins in liquefied gas (LPG) is 58% (others are alkanes), and the conversion rate of olefins is 90%, the temperature rise of each catalyst bed is controlled to 40°C, design 8 stage fixed bed reactor (such as figure 1 As shown, the experimental results are shown in Table 4). At the same time, the number of stages of the fixed bed reactor can be adjusted according to the LPG circulation amount of the injected saturated liquefied gas accounting for the raw material. The number of levels can be less, generally 4-8 levels.

[0031] Table 4 Example 1 The conversion rate of olefins in each stage of reaction bed is 90%, and the result of adiabatic temperature rise of each stage of bed

[0032]

Embodiment 2

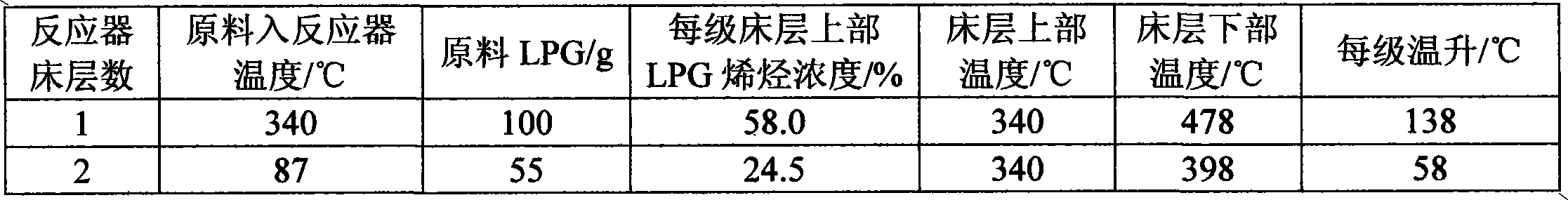

[0034] BTX aromatics from liquefied gas: When the concentration of olefins in liquefied gas (LPG) is 58% (others are alkanes), and the conversion rate of olefins is 90%, the temperature rise of each catalyst bed is pre-controlled to 50°C, and the design 6-stage fixed bed (experimental results are shown in Table 5), similar to the situation of liquefied gas to gasoline, the number of stages of the fixed-bed reactor can be adjusted according to the LPG circulation volume of the injected saturated hydrocarbon accounted for the raw material, if the circulation volume is high, in In the case of maintaining the temperature rise of catalyst beds at all levels at 50°C, the number of fixed-bed reactor stages can be less.

[0035] Table 5 Example 2 The conversion rate of olefins in each stage of the reaction bed is 90%, and the result of the adiabatic temperature rise of each stage of the bed

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com