Bentonite surface modification and intercalation technique

A mycotoxin adsorption and surface modification technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of not being able to simultaneously adsorb multiple mycotoxins in the feed, and possibly adsorbing nutrients or health care drugs in the feed. , to achieve the effect of no toxic and side effects, wide range of uses and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

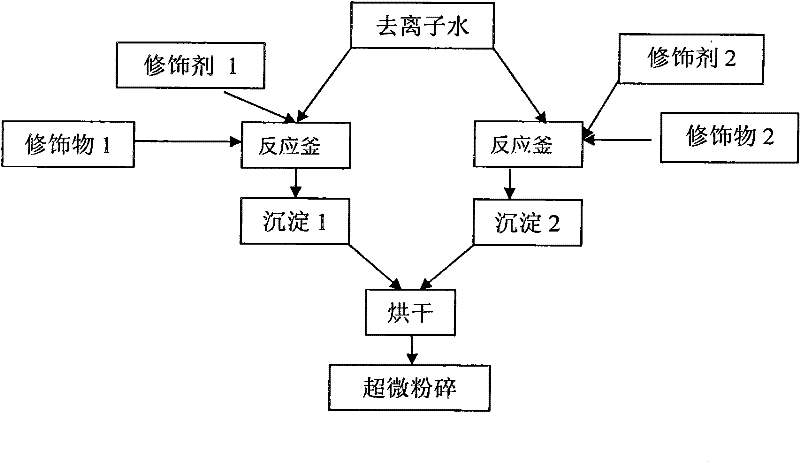

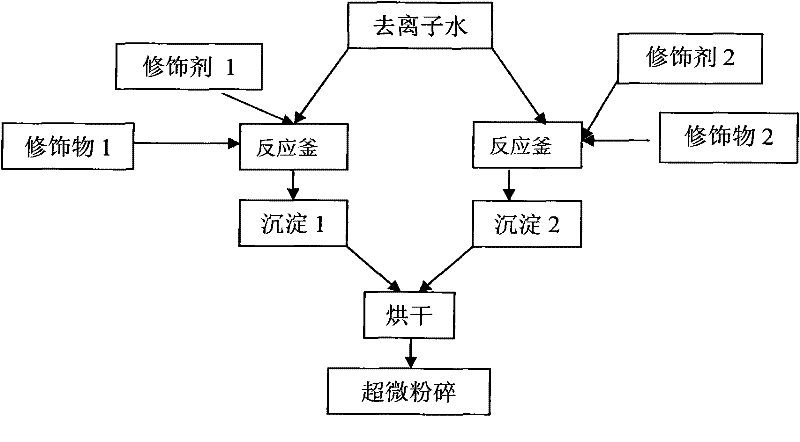

Method used

Image

Examples

Embodiment 1

[0032] Technology 1: Production of surface-modified bentonite, based on sodium-based bentonite, first put 0.1kg of cetylpyridinium chloride with a purity of 96% into the reactor, add 100L of deionized water to the reactor, and then react The kettle is heated, and the temperature is set to 60°C, the pressure in the reactor is set to normal pressure, and the reactor is stirred, the stirring time is 8 minutes, the stirring speed is 300rpm, and 10kg of sodium bentonite powder is added during the stirring process , During the stirring period, the high-speed shearing machine matched with the reactor is used for shearing every 3 minutes, the shearing speed is 2500rpm, and the shearing time is 1 minute. After shearing, it is emulsified, placed in a precipitator, and finally dried And crushing, the total time-consuming of the whole surface modification technology is about 55 minutes.

[0033] Technology 2: Production of intercalation bentonite, based on sodium bentonite, put 0.2kg of β...

Embodiment 2

[0036] Technology 1: Production of surface-modified bentonite, based on calcium-based bentonite, 1kg of cetylpyridinium chloride with a purity of 99%, 80L of deionized water, temperature of 180°C, pressure of 1MPa, stirring time of 15 minutes, stirring speed Be 800rmp, shear velocity and time are respectively 3500rpm and 1min, and other conditions and reaction process are identical with embodiment 1;

[0037] Technology 2: Production of intercalated bentonite, based on calcium-based bentonite, 1kg of β-glucan of 300,000 Daltons, 80L of deionized water, temperature of 60°C, pressure of 1MPa, stirring time of 15 minutes, stirring speed of 700rmp, shear velocity and time are respectively 3500rpm and 1min, and other conditions and operating process are exactly the same as in embodiment 1;

[0038] The results of techniques 1 and 2 were mixed and tested for aflatoxin B 1 It was found that the adsorption efficiency had significantly increased from 83.84% before modified intercalati...

Embodiment 3

[0040]Technology 1: Production of surface modified bentonite, based on sodium bentonite, 0.8kg of cetylpyridinium chloride with a purity of 98%, 100L of deionized water, temperature of 100°C, pressure of normal pressure, stirring time of 10 minutes, Stirring velocity is 600rmp, and shear rate and time are respectively 3000rpm and 1min, and other conditions and process are exactly the same as in Example 1;

[0041] Technology 2: Production of intercalated bentonite, based on nano-bentonite, 0.8kg of β-glucan of 280,000 Daltons, 100L of deionized water, temperature of 120°C, normal pressure, stirring time of 12 minutes, stirring speed Be 600rmp, shear velocity and time are respectively 3000rpm and 1min, and other conditions and operating process are identical with embodiment 1;

[0042] The results of techniques 1 and 2 were mixed and tested for aflatoxin B 1 The adsorption effect, found that the adsorption efficiency has significantly increased from 83.84% before modified inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com