Evaluation method of influence of optical element surface waviness on laser damage threshold and method for obtaining element optimal processing parameters therefrom

A technology of laser damage threshold and surface waviness, which is applied in the direction of optical components, optics, and testing optical performance, can solve problems such as inaccurate results and achieve high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

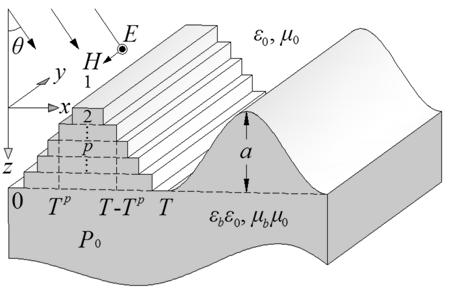

[0018] Specific implementation mode one : the evaluation method of the influence of the surface waviness of the optical element of the present embodiment on its laser damage threshold, its process is as follows:

[0019] Step 1. Obtain the shape data matrix of the original processed surface of the optical element by using the detection instrument;

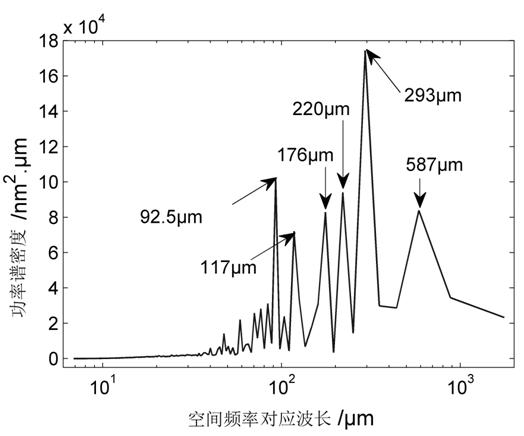

[0020] Step 2. According to the morphology data matrix obtained in step 1, the power spectral density curve of the original processed surface of the optical element is obtained, and then each characteristic frequency and the amplitude of each characteristic frequency of the original processed surface of the optical element are obtained;

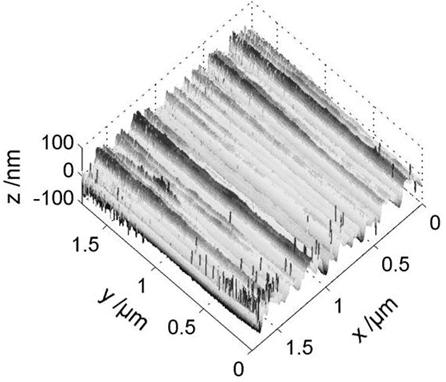

[0021] Step 3. For each characteristic frequency obtained in step 2, use the two-dimensional continuous wavelet transform method to extract and reproduce the three-dimensional shape of each characteristic frequency, and use the Fourier mode method to calculate the light intensity distribution ins...

specific Embodiment approach 2

[0025] Specific implementation mode two: This embodiment is a further description of the evaluation method of the influence of the surface waviness of the optical element on its laser damage threshold in the first embodiment. The specific process of the content described in step two is:

[0026] make z ( x ) represents the topography data matrix of the original processed surface of the optical element obtained in step 1, where z ( x ) contains N data points, and every two adjacent data points have the same sampling interval Δ x , the overall sampling length is L = N Δ x ;

[0027] The power spectral density is defined as the square of the Fourier spectrum amplitude of each frequency component of the wavefront, which is the result of Fourier transforming the surface profile function of the optical element in the space domain in the frequency domain, and its one-dimensional definition is ,in, ν is the spatial frequency, Δ ν is the frequency interval, A ( ν ) is t...

specific Embodiment approach 3

[0035] Specific implementation mode three: This embodiment is a further description of the evaluation method of the influence of the surface waviness of the optical element on its laser damage threshold in the first or second embodiment. The specific process of the content described in step three is:

[0036] The general form of two-dimensional continuous wavelet transform (CWT2D, ContinuousWaveletTransform2D) is:

[0037] ,

[0038] in, is the plane Cartesian coordinates, represents a two-dimensional signal, Represents a two-dimensional continuous wavelet transform, yes , displacement in the direction, , superscripts in expressions T means transpose, is the scale factor, is the coordinate rotation factor, is the counterclockwise rotation angle of the coordinate system, Represents the two-dimensional basic wavelet function The scaling, coordinate rotation and two-dimensional displacement of the for the conjugate;

[0039] Eigenfrequency f s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com