Measurement method and measurement accessory for zero point calibration of gear measuring center

A technology for gear measurement and zero point calibration, which is used in the testing of machine gear/transmission mechanism, measuring devices, instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

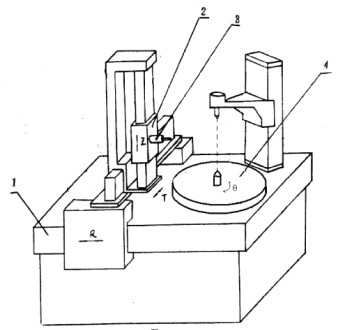

[0050] see Figure 7 The force is measured in the horizontal direction (T direction). The specific steps are:

[0051] 1. Place the standard ball 8 at a suitable position in the upper space of the rotary shaft table 4 of the gear measurement center through the attachment, so as to ensure that the measuring head 5 can touch the standard ball 8 within the stroke range;

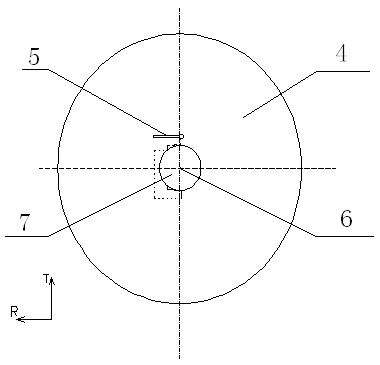

[0052] 2. According to the force measuring direction of the probe 5, manually move the probe 5 so that it is directly in front of the force measuring direction of the standard ball 8 (such as image 3 );

[0053] 3. Driven by the gear measurement center, drive the measuring head 5 to contact the standard ball 8, and measure six uniform points within the semicircle range of the horizontal section in contact with the standard ball 8 and the measuring head 5, and according to the least square circle The coordinate values of each axis of the center of the sphere (T1, R1, q1) are calculated by the method; the au...

Embodiment 2

[0059] For the gear measurement center using a three-dimensional measuring head, the method of Embodiment 1 can be used for zero point calibration.

Embodiment 3

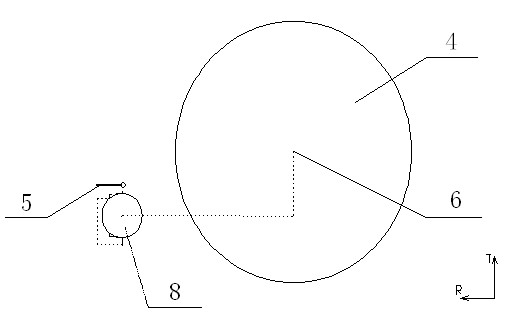

[0061] see Figure 8 , Measuring force of the probe 5 is in the vertical direction (Z direction). The specific implementation steps are as follows:

[0062] 1. After the gear measurement center is powered on, the indication values of the gratings on each axis will be cleared. Adsorb the standard ball 8 on the rotary table 4, manually move the measuring head 5 to the position 1 directly above the standard ball 8 (such as Figure 4 );

[0063] 2. Driven by the gear measurement center, the measuring head 5 is automatically driven to move along the R and Z directions, contact with the standard ball 8, and measure the uniformity within a quarter circle of the vertical section of the standard ball 8 and the measuring head 5. Six points, and calculate the R-axis coordinate value R1 of the center of the sphere based on the six points (such as Figure 5 );

[0064] 3. The measuring head 5 returns to the starting point, automatically drives the measuring head 5 to move along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com