Deepwater blowout preventer set electric control system based on FPGAs (Field Programmable Gate Arrays)

An electronic control system, blowout preventer technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of increasing manufacturing difficulty, reducing system safety, increasing the volume of blue-yellow electronic sealed cabins, etc. The effect of compactness, reduced size, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

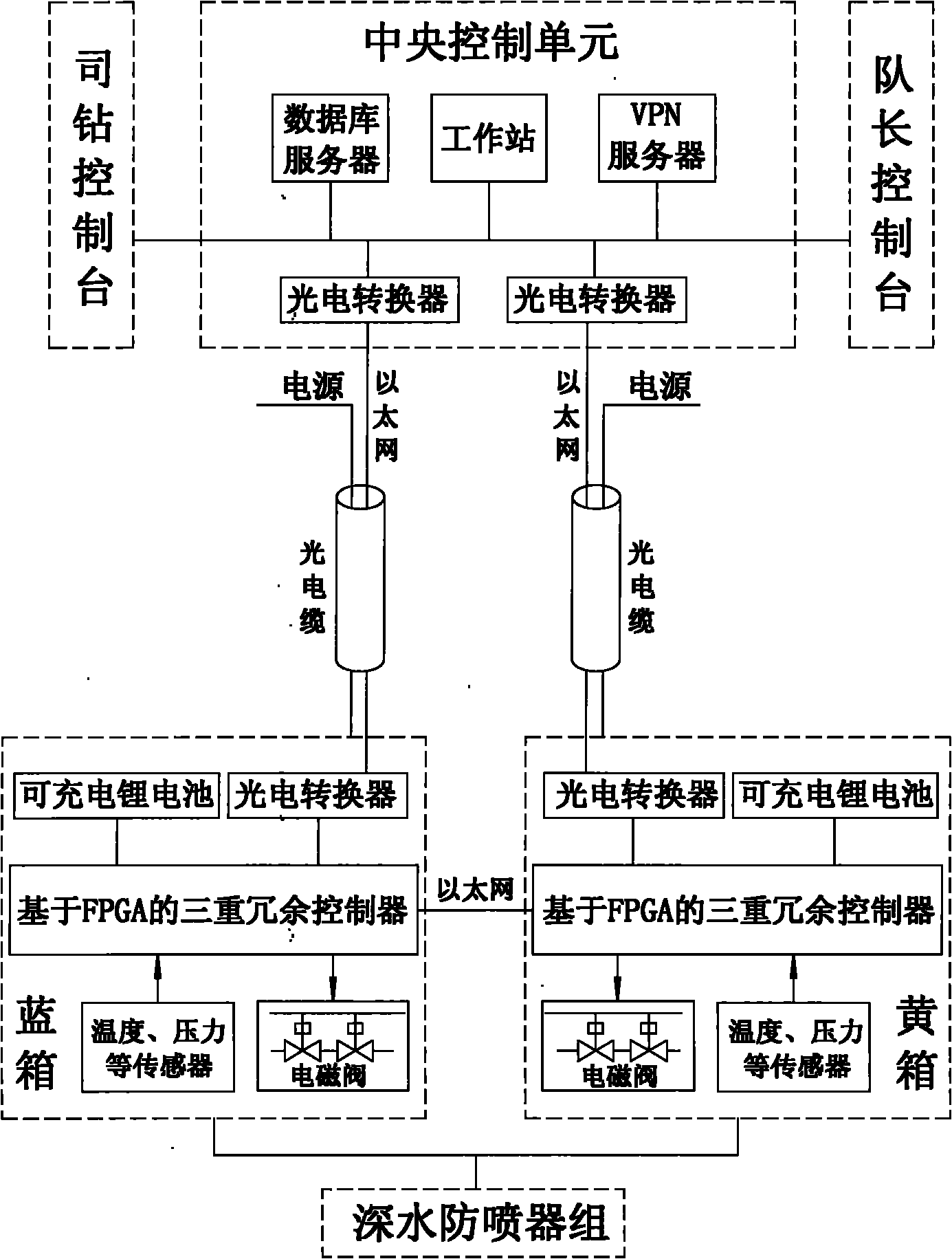

[0011] Such as figure 1 As shown, the FPGA-based deepwater BOP electronic control system is mainly composed of the above-water electric control system, the underwater electric control system and the transmission optical cable connecting the above-water and underwater systems. The water electronic control system is located on the drilling platform, mainly including the central control unit, the driller's console and the captain's console.

[0012] The central control unit is located in the safe area of the platform. It is the core of the electronic control system and provides communication interfaces for the driller's console, captain's console and underwater electronic modules. System workstations, database servers, VPN servers, network equipment and printing equipment are all located in the central console. The driller's console is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com